A method for preparing copper-zinc-tin-sulfur thin films based on water-based nano-ink

A nano-ink, copper-zinc-tin-sulfur technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inability to achieve good dispersion, easy generation of hydrogen sulfide gas, and solvents that are not environmentally friendly. Achieve good photoelectric conversion efficiency, stable and uniform properties, and improve the effect of compactness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A method for preparing copper-zinc-tin-sulfur film based on water-based nano-ink, comprising the following steps:

[0035] (1) Weigh 0.001mol of zinc acetate, 0.001mol of stannous chloride, 0.0018mol of copper nitrate and 0.009mol of thioacetamide and dissolve them in 50mL of ethylene glycol in sequence. After they are completely dissolved, add 0.64g of PVP to make a precursor body solution.

[0036] (2) The precursor solution was heated by microwave, the microwave power was 400W, and the microwave time was 10min to prepare Cu 2 ZnSnS 4 Nanoparticle ink.

[0037] (3) Apply the nano-ink to the glass substrate and place it in a vacuum annealing furnace. Under a nitrogen atmosphere, the temperature was raised to 400°C at 10°C / min, kept for 60 minutes, and then cooled to room temperature with the furnace.

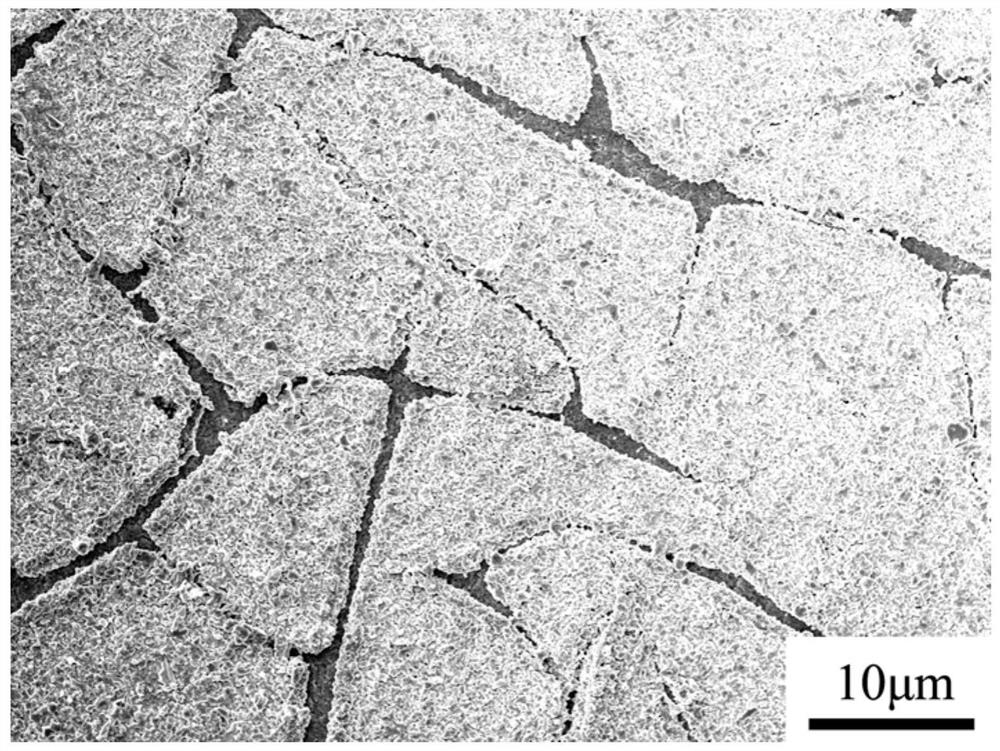

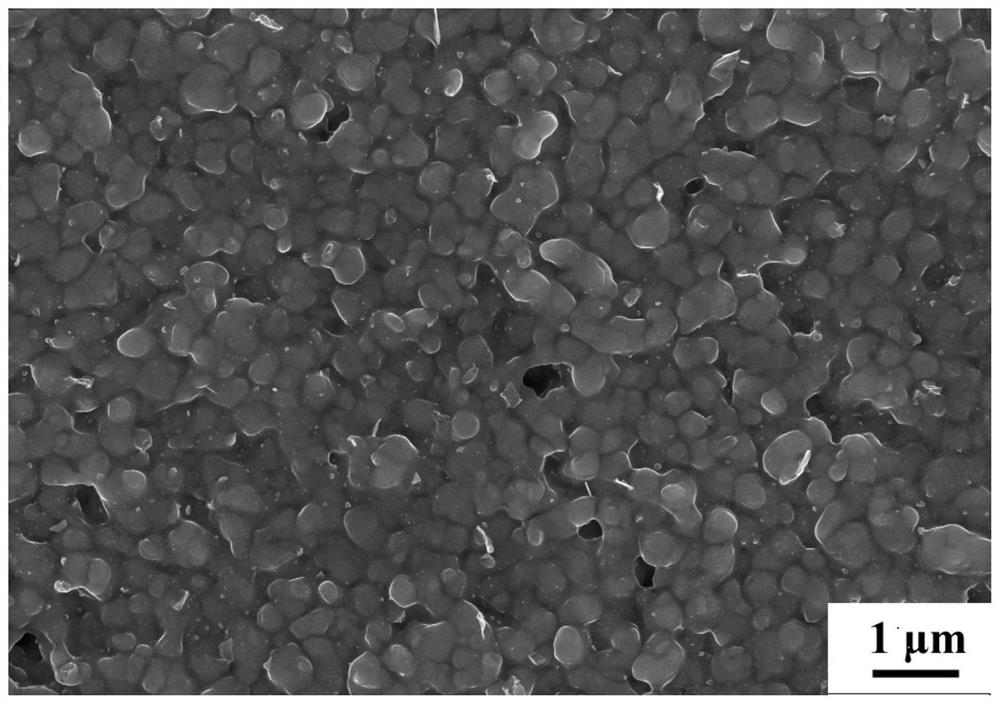

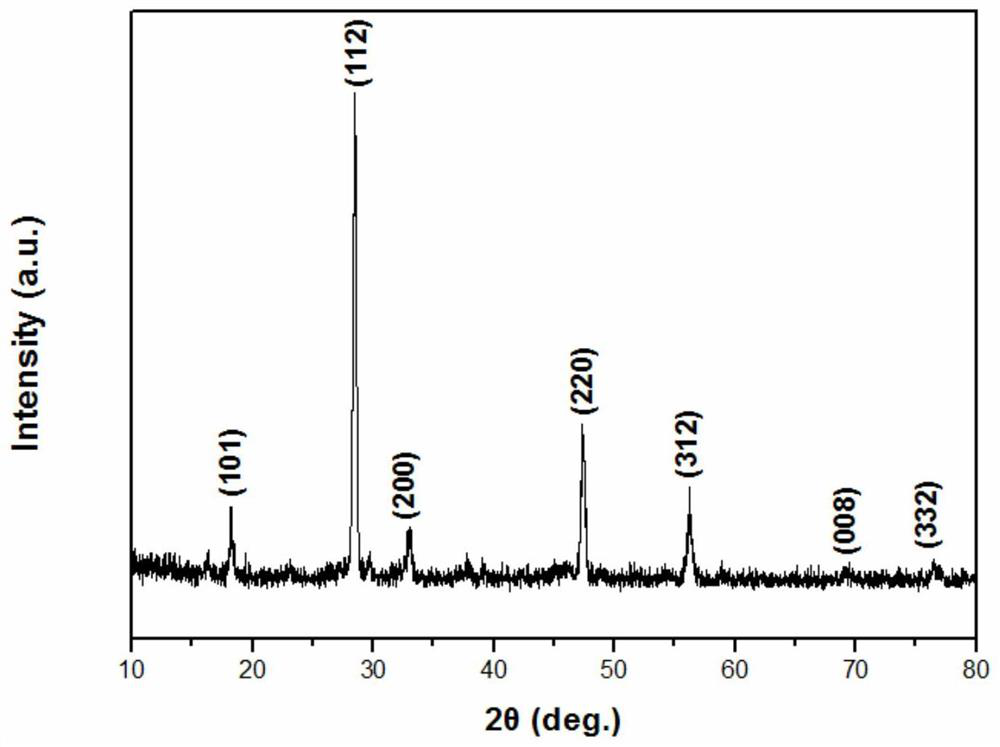

[0038] To test the obtained products, figure 1 For the prepared Cu 2 ZnSnS 4 The SEM picture of the film shows that compared with the film prepared in the comparat...

Embodiment 2

[0040] A method for preparing copper-zinc-tin-sulfur film based on water-based nano-ink, comprising the following steps:

[0041] (1) Weigh 0.001mol of zinc acetate, 0.0012mol of stannous chloride, 0.00176mol of copper chloride and 0.0396mol of thiourea and dissolve them in 50mL of n-propanol. After they are completely dissolved, add 0.7g of PVP to prepare a precursor solution.

[0042] (2) microwave the precursor solution by microwave method, the microwave power is 600W, and the microwave time is 8min to obtain Cu 2 ZnSnS 4 nano ink.

[0043] (3) Apply the nano-ink to the glass substrate and place it in a vacuum annealing furnace. In an argon atmosphere, heat up to 500°C at 20°C / min, hold for 20 minutes, and then cool to room temperature with the furnace to obtain denser Cu 2 ZnSnS 4 film.

Embodiment 3

[0045] A method for preparing copper-zinc-tin-sulfur film based on water-based nano-ink, comprising the following steps:

[0046] (1) Weigh 0.001mol of zinc chloride, 0.0008mol of stannous chloride, 0.0018mol of cupric chloride and 0.018mol of L-cysteine and dissolve them in 50mL of glycerol, stir evenly to make them completely dissolve in the acetone In the triol, add 0.4g PVP to prepare the precursor solution.

[0047] (2) microwave the precursor solution by microwave method, the microwave power is 50W, and the microwave time is 30min to obtain Cu 2 ZnSnS 4 nano ink.

[0048] (3) Apply the nano-ink to the glass substrate and place it in a vacuum annealing furnace. In a nitrogen atmosphere, heat up to 300°C at 5°C / min, hold for 120 minutes, and then cool to room temperature with the furnace to obtain denser Cu 2 ZnSnS 4 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com