A kind of core-shell structure cobalt disulfide composite material and preparation method thereof

A technology of cobalt disulfide and composite materials, applied in structural parts, secondary batteries, electrochemical generators, etc., can solve the problems of poor long-term cycle performance of batteries, shortened battery life, poor conductivity of cobalt disulfide, etc. Multiple reactive active sites, preventing material pulverization, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

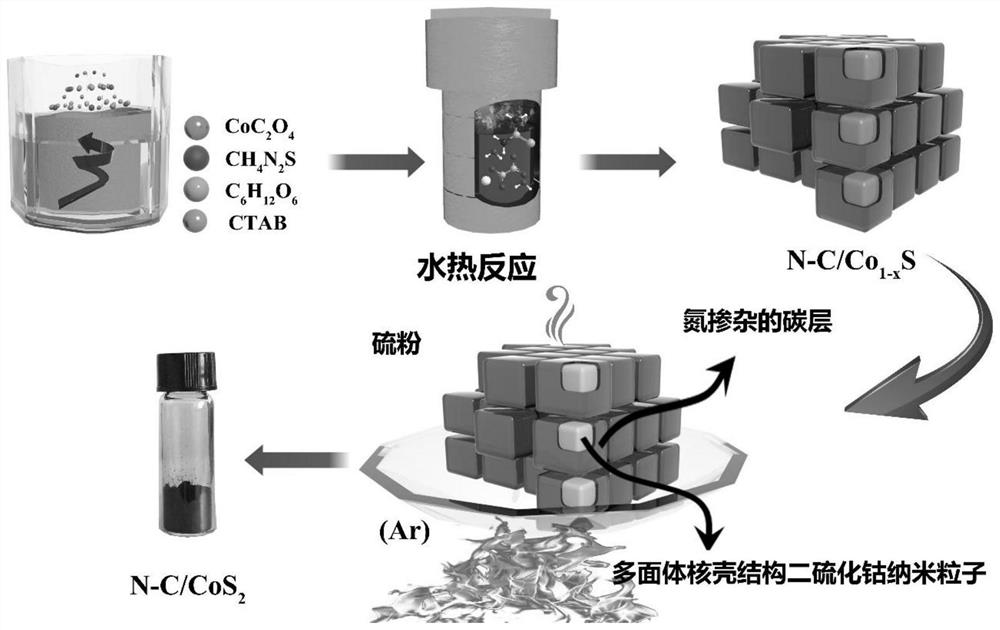

[0032] The invention provides a method for preparing a core-shell structure cobalt disulfide composite material, comprising: S1) combining an organic acid cobalt salt, an organic sulfur source, a glycol solvent, cetyltrimethylammonium bromide and organic carbon Sources are mixed, and after hydrothermal reaction, an intermediate product is obtained; the organic sulfur source contains amino groups; S2) the intermediate product is mixed with sulfur powder, and annealed in a protective atmosphere to obtain a core-shell structure cobalt disulfide composite material.

[0033] see figure 1 , figure 1 Schematic diagram of the synthesis of the core-shell structure cobalt disulfide composite material provided by the present invention.

[0034] The preparation method of the invention is simple, good in repeatability and short in cycle. In this method, a cobalt disulfide phase can be formed only by hydrothermal self-assembly, and then annealed to obtain a high-performance core-shell str...

Embodiment 1

[0050] Mix 0.7g of cobalt oxalate tetrahydrate and 0.18g of thiourea into a beaker filled with 70ml of ethylene glycol and stir in a water bath. The temperature of the water bath is 45°C and the stirring time is 15min; Trimethylammonium bromide and 0.7 g of glucose were added to the above solution, and the water bath was continued to stir and mix evenly. The temperature of the water bath was 45° C., and the stirring time was 30 min.

[0051] Pour the homogeneous solution after mixing and dissolving into a stainless steel reaction kettle and seal it. Then put the stainless steel reaction kettle into a blast oven at 180°C, and place it at a constant temperature for 12h. After the reaction, take out the suspension in the reaction kettle. Then the suspension was centrifuged, the centrifugation speed was set to 10000r / min, and the centrifugation time was 20min. The separated solid precipitate was placed in a vacuum oven at 50° C., baked for 10 h, and then taken out.

[0052] Tak...

Embodiment 2

[0056]Mix 0.7g of cobalt oxalate tetrahydrate and 0.18g of thiourea into a beaker containing 70ml of ethylene glycol and stir in a water bath. The temperature of the water bath is 45°C and the stirring time is 15min. Then weigh 1.0 g of cetyltrimethylammonium bromide and 0.5 g of glucose and add them to the above solution, and continue stirring in a water bath to mix evenly. The temperature of the water bath is 45° C., and the stirring time is 30 min.

[0057] Pour the homogeneous solution after mixing and dissolving into a stainless steel reaction kettle and seal it. Then put the stainless steel reaction kettle into a blast oven at 180°C, and place it at a constant temperature for 12h. After the reaction, take out the suspension in the reaction kettle. Then the suspension was centrifuged, the centrifugation speed was set to 10000r / min, and the centrifugation time was 20min. The separated solid precipitate was placed in a vacuum oven at 50° C., baked for 10 h, and then taken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com