A preparation method of N-doped carbon-coated Mo2C/C functional composite material and application thereof in lithium sulfur battery

A functional composite material, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity, poor polysulfide confinement performance, etc., and achieve good structural stability, good cycle stability, shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] N-doped Mo at pH 8.5 2 The preparation of the C / C precursor specifically includes the following steps:

[0055] (1) 500 mg of ammonium molybdate tetrahydrate was dissolved in 150 mL of deionized water, and stirred at room temperature for 10 minutes;

[0056] (2) Add 600 mg of dopamine hydrochloride to the solution in (1), and keep magnetic stirring at room temperature;

[0057] (3) Add 300 ml of absolute ethanol into the solution of (2), and continue to stir for 30 minutes;

[0058] (4) Finally, add 1mL of 25wt% ammonia water into the mixed solution of (3), adjust the pH value of the mixed solution to 8.5, and continue to react for 2 hours;

[0059] (5) Collect the precipitate in (4) by centrifugation to obtain the precursor powder, wash with deionized water and absolute ethanol three times each, put it in an oven, and dry at 80°C for 8 hours;

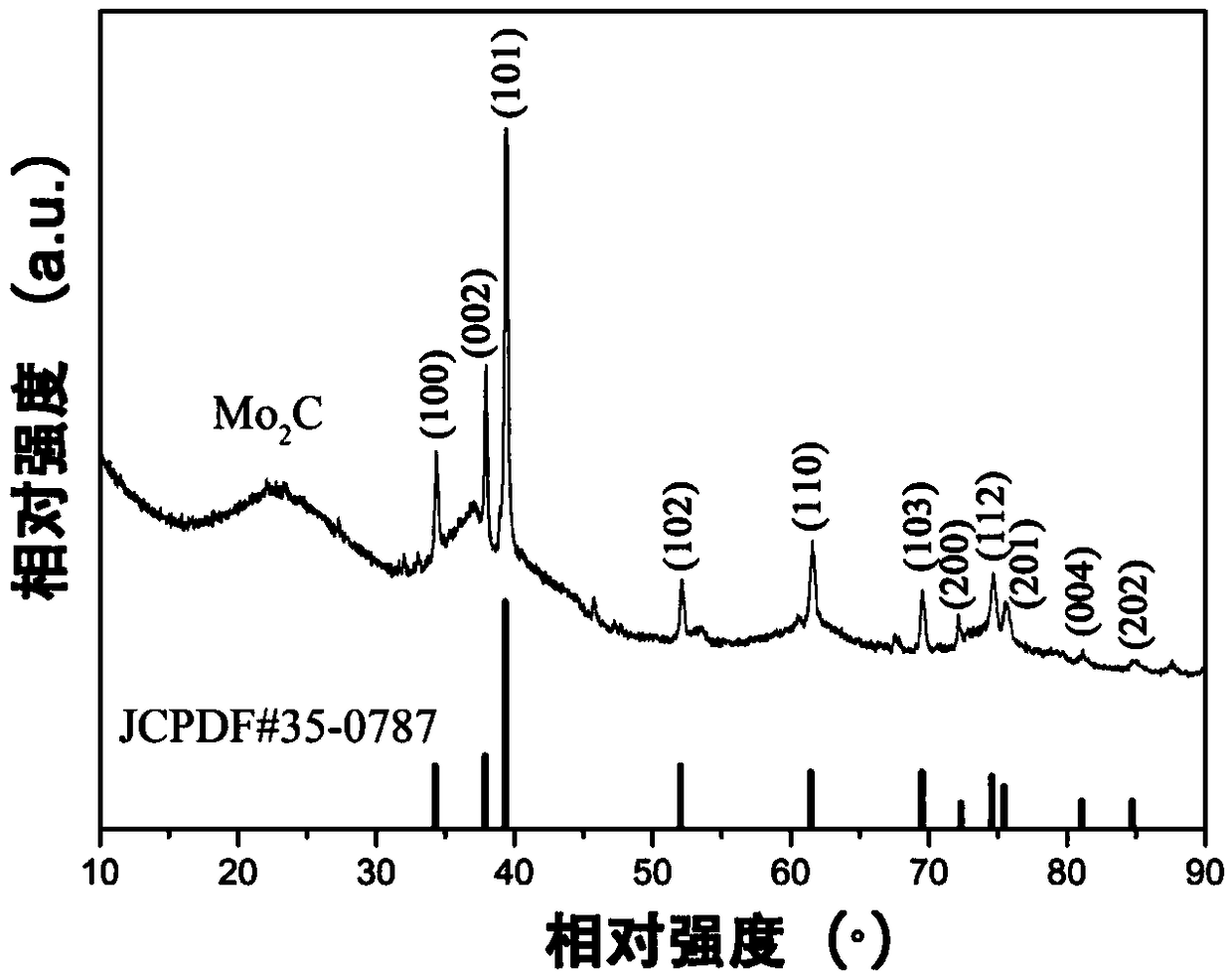

[0060] The SEM image of the obtained precursor powder is as follows figure 1 shown by figure 1 It can be seen that the di...

Embodiment 2

[0062] N-doped Mo at pH 8.8 2 The preparation of the C / C precursor specifically includes the following steps:

[0063] (1) 500 mg of ammonium molybdate tetrahydrate was dissolved in 150 mL of deionized water, and stirred at room temperature for 10 minutes;

[0064] (2) Add 600 mg of dopamine hydrochloride to the solution in (1), and keep magnetic stirring at room temperature;

[0065] (3) Add 300 ml of absolute ethanol into the solution of (2), and continue to stir for 30 minutes;

[0066] (4) Finally, add 1mL of 25-28wt% ammonia water into the mixed solution of (3), adjust the pH value of the mixed solution to 8.8, and continue to react for 2 hours;

[0067] (5) Collect the precipitate in (4) by centrifugation to obtain the precursor powder, wash with deionized water and absolute ethanol three times each, put it in an oven, and dry at 80°C for 8 hours;

[0068] For the SEM image of the obtained precursor powder, see figure 1 , the precursor is a sphere with a uniform size...

Embodiment 3

[0070] N-doped Mo at pH 9.0 2 The preparation of the C / C precursor specifically includes the following steps:

[0071] (1) 500 mg of ammonium molybdate tetrahydrate was dissolved in 150 mL of deionized water, and stirred at room temperature for 10 minutes;

[0072] (2) Add 600 mg of dopamine hydrochloride to the solution in (1), and keep magnetic stirring at room temperature;

[0073] (3) Add 300 ml of absolute ethanol into the solution of (2), and continue to stir for 30 minutes;

[0074] (4) Finally, add 1 mL of concentrated ammonia water into the mixed solution of (3), adjust the pH value of the mixed solution to 9.0, and continue to react for 2 hours;

[0075] (5) Collect the precipitate in (4) by centrifugation to obtain the precursor powder, wash with deionized water and absolute ethanol three times each, put it in an oven, and dry at 80°C for 8 hours;

[0076] For the SEM image of the obtained precursor powder, see figure 1 , the precursor is a sphere with a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com