Piezoelectric composite material based on β-phase polyvinylidene fluoride and its preparation method

A piezoelectric composite material, polyvinylidene fluoride technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of conductivity affecting polymerization Polarization process, unfavorable standardized production and application, low polyvinylidene fluoride β-phase content, etc., to achieve the effect of simple and convenient preparation method and process, simple and easy-to-operate equipment, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a kind of preparation dabcoHReO 4 salt method. Specifically include the following steps:

[0043] 1) Dissolve 1,4-diazabicyclo[2.2.2]octane (dabco) in ultrapure water at room temperature, and the mass ratio of dabco to ultrapure water is 20:100.

[0044] 2) After complete dissolution, press 1,4-diazabicyclo[2.2.2]octane (dabco) and perrhenic acid (HReO 4 ) molar ratio is 1:1, add perrhenic acid (HReO 4 ) aqueous solution. After acid-base neutralization reaction, dabcoHReO is obtained 4 Salt.

[0045] 3) dabcoHReO at room temperature 4 The salt was dissolved in water again, and after the dissolution was complete, the dabcoHReO 4 Put the saline solution into an ultra-low temperature refrigerator and freeze until it becomes completely solid, take it out, and use a freeze dryer to remove the solid water to obtain dabcoHReO 4 salt solids.

Embodiment 2

[0047] For comparison, this example provides a method for preparing a polyvinylidene fluoride film. Specifically include the following steps:

[0048] 1) Dissolve an appropriate amount of PVDF powder in a mixed solution of DMF / AC (volume ratio = 1:1), heat ultrasonically in an ultrasonic instrument at 50°C for 3 hours to promote the complete dissolution of PVDF powder, and let it stand at room temperature for more than 24 hours. Ensure that the sample is completely dissolved, and prepare a PVDF solution with a mass concentration of 10 wt%.

[0049] 2) Evaporate and crystallize the prepared solution in an oven at 70°C. After the solvent is completely volatilized, a film with uniform thickness is prepared. After 5 hours of heat treatment, the oven is closed, and the PVDF film is obtained after natural cooling to room temperature.

Embodiment 3

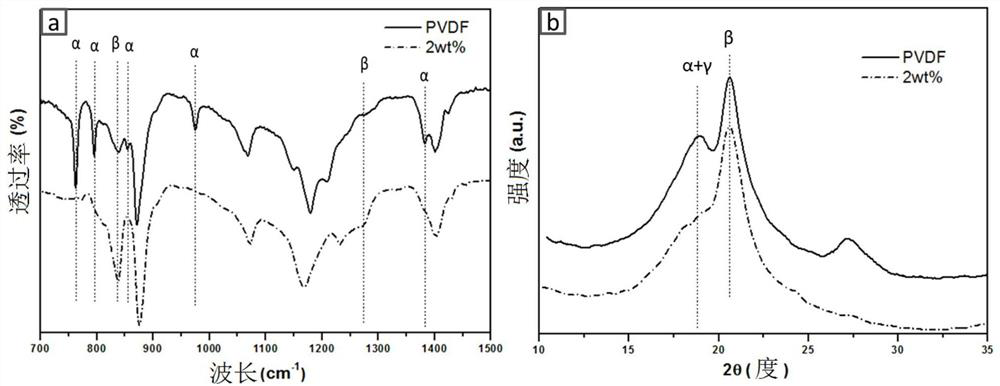

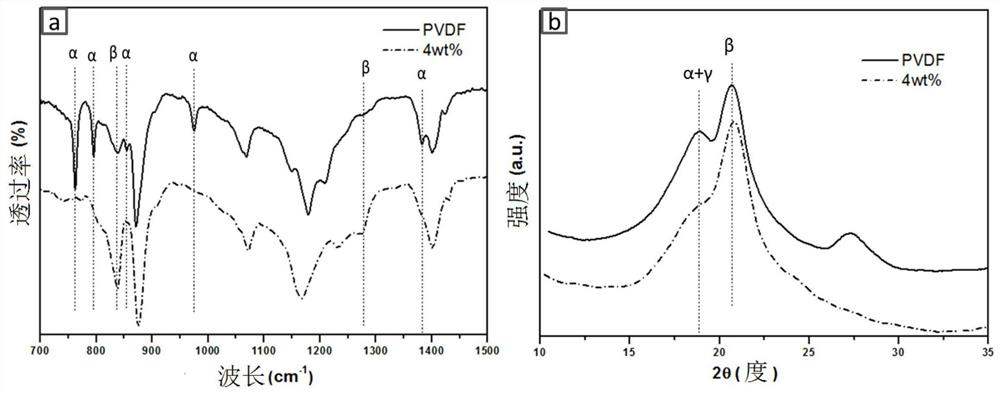

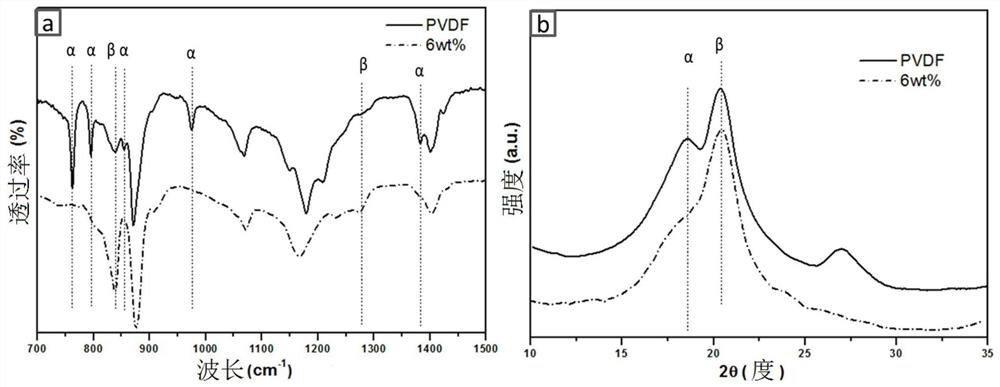

[0051] This example provides a method for preparing a high-content β-phase polyvinylidene fluoride composite material, specifically dabcoHReO prepared in Example 1 4 Salt is mixed with PVDF according to a certain mass ratio, and PVDF / dabcoHReO is prepared 4 Composite film. The method effectively increases the polyvinylidene fluoride β-phase content. Specifically include the following steps:

[0052] 1) Dissolve an appropriate amount of PVDF powder in a mixed solution of DMF / AC (volume ratio = 1:1), and heat ultrasonically in an ultrasonic instrument at 50°C for 3 hours to promote complete dissolution of the PVDF powder. Let stand at room temperature for 8 hours.

[0053] 2) will dabcoHReO 4 Mix salt and PVDF according to the mass ratio of 2:98, heat ultrasonically in a 50°C ultrasonic instrument for 3 hours, and let it stand at room temperature for more than 24 hours to ensure that the sample is completely dissolved to obtain a mixed solution. In the mixed solution, dabcoH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com