A kind of preparation method of the highly dispersible pigment that is used for PVC film structure material

A technology with high dispersibility and film structure, applied in inorganic pigment treatment, chemical instruments and methods, dyed polymer organic compound treatment, etc., can solve the problems of high price and difficult to fold, and achieve high industrial use value and great economy. and social benefits, effects of excellent dispersibility and dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

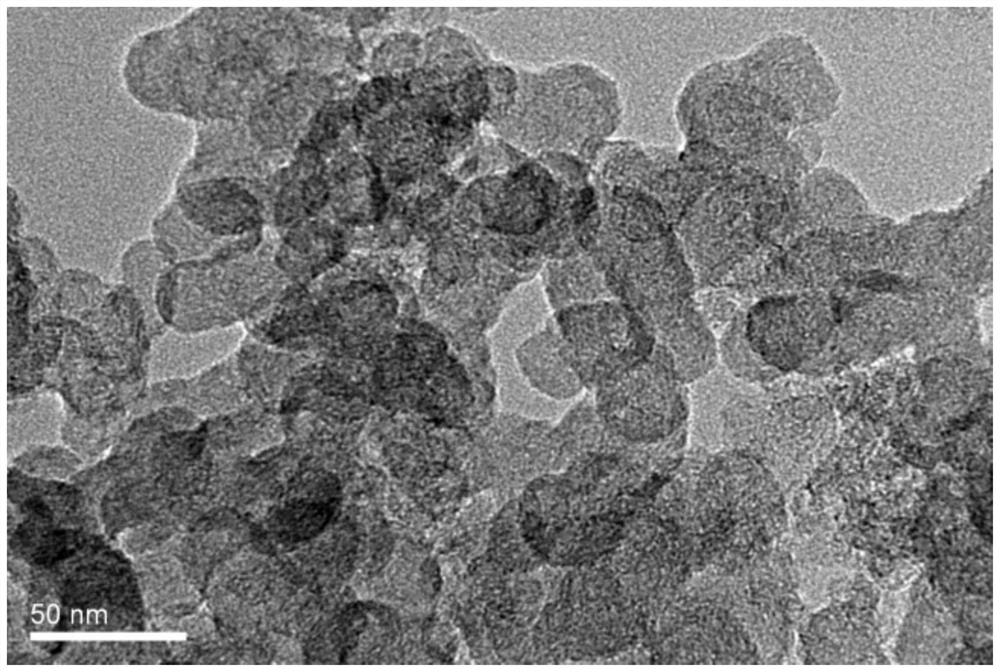

[0037] Embodiment 1: Preparation of highly dispersible pigment

[0038] 1) Dry 10kg of carbon black at 80°C for 1 hour, and then pour it into the reaction kettle.

[0039] 2) Add 500kg of acetone and 1kg of silane coupling agent KH560 into the reaction kettle, mix and stir, react at a temperature of 75°C for 30min, and then remove the solvent acetone by rotary evaporation at 65°C.

[0040] 3) Add 1 kg of epoxidized soybean oil into the reaction kettle for mixing and stirring, and react at a temperature of 75° C. for 30 minutes to obtain modified carbon black for direct use in the next step.

[0041] 4) Then take 5 kg of modified carbon black and add it to 37 kg of plasticizer (dioctyl terephthalate DOTP) for mixing, and add 2 kg of dispersant (sodium polystyrene sulfonate), and stir for 1 min.

[0042] 5) Continue to add viscosity control agent: 30kg of nano-calcium carbonate with a particle size of 100nm, stir for 5min, and let stand for 2h.

[0043] 6) Add the solution aft...

Embodiment 2

[0047] Embodiment 2: Preparation of highly dispersible pigment

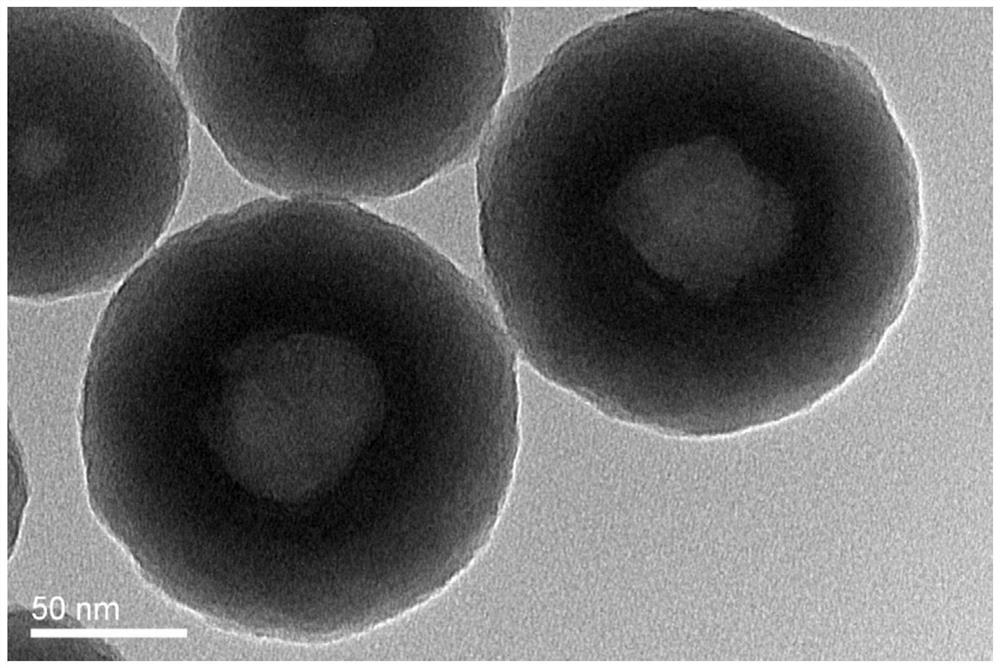

[0048] Prepare according to the preparation process of Example 1, the difference is that the quality of the plasticizer (dioctyl terephthalate DOTP) in step 4) is 50kg, and the viscosity can be obtained equally as a highly dispersible pigment of 25000cps, The microscopic morphology of the pigment powder is a core-shell structure with excellent dispersibility.

Embodiment 3

[0049] Embodiment 3: prepare highly dispersible pigment

[0050] Prepare according to the preparation process of Example 1, the difference is that the quality of plasticizer (dioctyl terephthalate DOTP) in step 4) is 60kg, can obtain the high dispersibility pigment that viscosity is 20000cps equally, The microscopic morphology of the pigment powder is a core-shell structure with excellent dispersibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com