Special anticorrosive paint for power distribution cabinet shell and preparation method thereof

A technology of anti-corrosion paint and power distribution cabinet, applied in anti-corrosion paint, coating and other directions, can solve the problem of weakening anti-corrosion effect, and achieve the effect of strong adhesion, stable performance and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

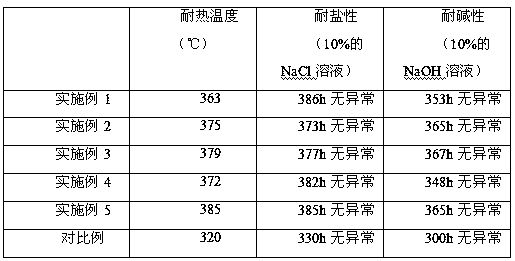

Examples

Embodiment 1

[0028] This embodiment relates to a special anti-corrosion paint for the shell of a power distribution cabinet, including the following raw materials in parts by weight: 15 parts of methylphenyl polysiloxane resin, 10 parts of acrylic resin, 12 parts of epoxy resin, 7 parts of butyl acrylate, 6 parts of modified talc powder, 2 parts of dioctyl phthalate, 1 part of fatty alcohol polyoxyethylene ether, 2 parts of calcium stearate, 1 part of boron nitride, 2 parts of plant extract, 1 part of ultraviolet absorber , 2 parts of leveling agent, 2 parts of anti-settling agent and 20 parts of solvent.

[0029] Wherein, the preparation method of described modified talcum powder is as follows:

[0030] Weigh talcum powder, bentonite, jade powder, and boron mud in a weight ratio of 6:3:2:1 and mix evenly, add 1.5% triethanolamine, 2% sodium polyacrylate, 1.5% calcium lignosulfonate, 0.6% Vinyl tris (β-methoxyethoxy) silane, 2000rpm high-speed grinding for 15min, drying, crushing, passing...

Embodiment 2

[0042] This embodiment relates to a special anti-corrosion paint for the shell of a power distribution cabinet, including the following raw materials in parts by weight: 25 parts of methylphenylpolysiloxane resin, 20 parts of acrylic resin, 18 parts of epoxy resin, 14 parts of butyl acrylate, 9 parts of modified talc powder, 4 parts of dioctyl phthalate, 3 parts of fatty alcohol polyoxyethylene ether, 4 parts of calcium stearate, 3 parts of boron nitride, 5 parts of plant extract, 3 parts of ultraviolet absorber , 4 parts of leveling agent, 5 parts of anti-settling agent and 30 parts of solvent.

[0043] Wherein, the preparation method of described modified talcum powder is as follows:

[0044] Weigh talcum powder, bentonite, jade powder, and boron mud in a weight ratio of 6:3:2:1 and mix evenly, add 1.5% triethanolamine, 2% sodium polyacrylate, 1.5% calcium lignosulfonate, 0.6% Vinyl tris (β-methoxyethoxy) silane, 2000rpm high-speed grinding for 15min, drying, crushing, passin...

Embodiment 3

[0056] This embodiment relates to a special anti-corrosion paint for the shell of a power distribution cabinet, including the following raw materials in parts by weight: 18 parts of methylphenylpolysiloxane resin, 13 parts of acrylic resin, 14 parts of epoxy resin, 10 parts of butyl acrylate, 7 parts of modified talc powder, 2.5 parts of dioctyl phthalate, 1.6 parts of fatty alcohol polyoxyethylene ether, 2.8 parts of calcium stearate, 1.3 parts of boron nitride, 3 parts of plant extract, 1.5 parts of ultraviolet absorber , 2.7 parts of leveling agent, 3 parts of anti-settling agent and 23 parts of solvent.

[0057] Wherein, the preparation method of described modified talcum powder is as follows:

[0058] Weigh talcum powder, bentonite, jade powder, and boron mud in a weight ratio of 6:3:2:1 and mix evenly, add 1.5% triethanolamine, 2% sodium polyacrylate, 1.5% calcium lignosulfonate, 0.6% Vinyl tris (β-methoxyethoxy) silane, 2000rpm high-speed grinding for 15min, drying, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com