Preparation method of biomass liquefied fuel oil

A biomass and fuel oil technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve environmental pollution and other problems, and achieve the effects of improving catalytic efficiency, increasing looseness, and increasing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

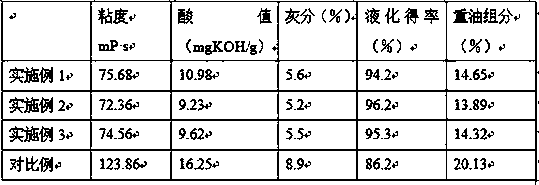

Examples

preparation example Construction

[0025] A preparation method of biomass liquefied fuel oil, the preparation method comprising the steps of:

[0026] (1) Mix the raw materials, additives and water evenly according to the mass ratio of 6~7:1:3~5, steam explosion, set the pressure at 1~3MPa, maintain the pressure for 70s, collect the steam explosion, filter, collect the filter residue, and put Squeeze the filter residue at 4MPa for 30s, then put it into a loose machine to break up, and collect the broken matter;

[0027] (2) Soak the scattered matter in acetic acid solution for 2 hours according to the mass ratio of 1:3~5, filter, wash until neutral, collect the washings, count by weight parts, take 30~40 parts of washings, 120~ 130 parts of water, 7 to 9 parts of ferric sulfate, 6 to 8 parts of additives, placed in a container for ultrasonic vibration for 20 minutes;

[0028] (3) After the ultrasonic vibration is finished, add the mixed liquid in an amount of 30-32% of the water quality, heat to 40-45°C, stir ...

Embodiment 1

[0031] The raw material is to mix wheat stalks, corn stalks and sawdust evenly in a mass ratio of 3:5:9, put them into a pulverizer for crushing, and collect the crushed materials to obtain the raw materials.

[0032] The additive is mixed with ammonium bicarbonate and sodium bicarbonate at a mass ratio of 5:1.

[0033] The auxiliary agent is mixed with manganese sulfate and nickel nitrate in a mass ratio of 6:1.

[0034] The mixed solution is prepared by mixing sucrose and ammonium oxalate solution at a mass ratio of 4:20.

[0035] The mixed solution is formed by mixing methanol solution and acetone at a volume ratio of 5:4.

[0036] A preparation method of biomass liquefied fuel oil, the preparation method comprising the steps of:

[0037] (1) Mix the raw materials, additives, and water evenly according to the mass ratio of 7:1:5, steam explosion, set the pressure at 3MPa, maintain the pressure for 70s, collect the steam explosion, filter, collect the filter residue, and s...

Embodiment 2

[0042] The raw material is to mix wheat stalks, corn stalks and sawdust evenly in a mass ratio of 2:3:7, put them into a pulverizer for crushing, and collect the crushed materials to obtain the raw materials.

[0043] The additive is mixed with ammonium bicarbonate and sodium bicarbonate at a mass ratio of 4:1.

[0044] The auxiliary agent is mixed with manganese sulfate and nickel nitrate in a mass ratio of 5:1.

[0045] The mixed solution is prepared by mixing sucrose and ammonium oxalate solution at a mass ratio of 3:15.

[0046] The mixed solution is formed by mixing methanol solution and acetone at a volume ratio of 4:4.

[0047] A preparation method of biomass liquefied fuel oil, the preparation method comprising the steps of:

[0048] (1) Mix the raw materials, additives, and water evenly according to the mass ratio of 6.5:1:4, steam explosion, set the pressure at 2MPa, maintain the pressure for 70s, collect the steam explosion, filter, collect the filter residue, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com