Ferroferric oxide nanoparticles as well as preparation method and application thereof in inhibiting proliferation of Salmonella

A technology of ferric oxide and nanoparticles, applied in the direction of iron oxide/hydroxide, application, nanotechnology, etc., can solve the problem of unreported and proven bactericidal effect, high cost of Salmonella purification, and increased drug resistance of chickens, etc. problem, achieve the effect of reducing Salmonella infection, low cost of use, and reducing pathological changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of iron ferric oxide nanoparticles comprises the following steps:

[0027] (1) Dissolve 0.8g ferric ferric oxide in 40mL of ethylene glycol solution (mass fraction is 60%), then add 3.5g sodium acetate, add to the hydrothermal reaction kettle after fully stirring, feed nitrogen, React at a temperature of 160°C for 12 hours to generate a precipitated product;

[0028] (2) Cool the precipitated product to room temperature, carry out ultrasonic dispersion after mechanical stirring, the frequency of ultrasonic is 40khz, and the time of ultrasonic dispersion is 4min;

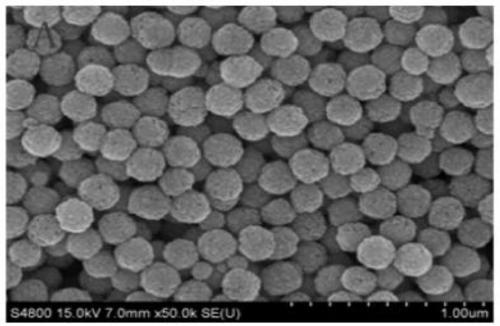

[0029] (3) The dispersed product was cross-washed with distilled water and ethanol until the pH of the supernatant was 6.8. After vacuum drying, ferric oxide nanoparticles were obtained, and the average diameter of the ferric oxide nanoparticles was 250nm.

Embodiment 2

[0031] A preparation method of iron ferric oxide nanoparticles comprises the following steps:

[0032] (1) Dissolve 0.82g ferric ferric oxide in 45mL of ethylene glycol solution (mass fraction is 60%), then add 3.6g sodium acetate, add to the hydrothermal reaction kettle after fully stirring, feed nitrogen, React at a temperature of 180°C for 8 hours to generate a precipitated product;

[0033] (2) Cool the precipitated product to room temperature, carry out ultrasonic dispersion after mechanical stirring, the frequency of ultrasonic wave is 40khz, and the time of ultrasonic dispersion is 5min;

[0034] (3) The dispersed product was cross-washed with distilled water and ethanol until the pH of the supernatant was 7.0, and vacuum-dried to obtain ferric oxide nanoparticles with an average diameter of 200 nm.

Embodiment 3

[0036] A preparation method of iron ferric oxide nanoparticles comprises the following steps:

[0037] (1) 0.85g of ferric oxide is dissolved in 50mL of ethylene glycol solution (mass fraction is 60%), then add 4.0g of sodium acetate, add to the hydrothermal reaction kettle after fully stirring, feed nitrogen, React at a temperature of 200°C for 6 hours to generate a precipitated product;

[0038] (2) Cool the precipitated product to room temperature, carry out ultrasonic dispersion after mechanical stirring, the frequency of ultrasonic is 40khz, and the time of ultrasonic dispersion is 6min;

[0039] (3) The dispersed product was cross-washed with distilled water and ethanol until the pH of the supernatant was 6.8, and vacuum-dried to obtain ferric oxide nanoparticles with an average diameter of 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com