Preparation method of copper/graphene core-shell structure

A core-shell structure, graphene technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of uneven compounding and weak connection between graphene and copper particles, and achieve increased elasticity and toughness. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Put 0.1g of copper nanospheres with a size of 100-200nm into a CVD tube furnace, the flow rate of hydrogen and argon is 100sccm, the flow rate of acetylene is 5sccm, the temperature is 1000°C, and the time is 45min to form the initial core-shell structure .

[0025] (2) Ultrasonic dispersion of 10 mg of graphene powder with a size of 100-1000 nm in 20 mL of N-methylpyrrolidone, and ultrasonication for 1 h.

[0026] (3) After finishing the ultrasound, quickly add the initial core-shell structure into the solution and stir for 1 hour to obtain the copper / graphene core-shell structure.

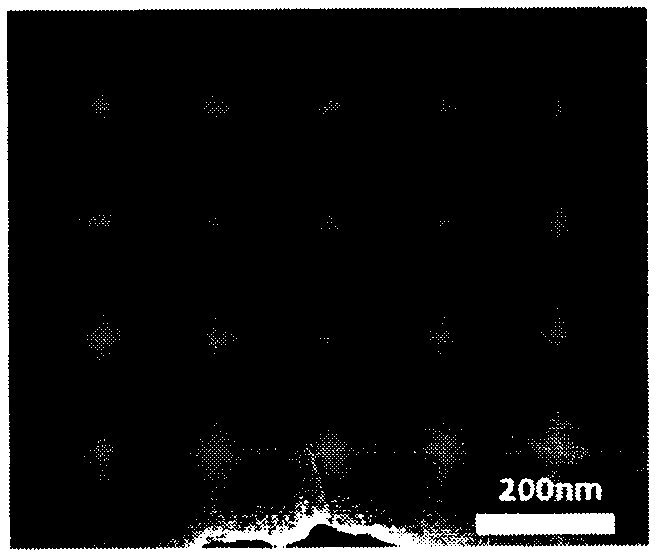

[0027] figure 1 A TEM image of graphene was used for this example.

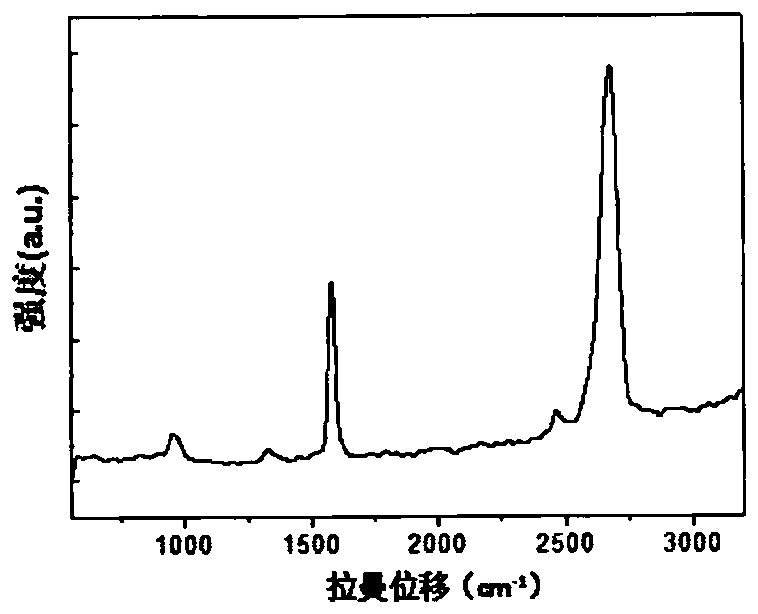

[0028] figure 2 A Raman map of graphene was used for this example.

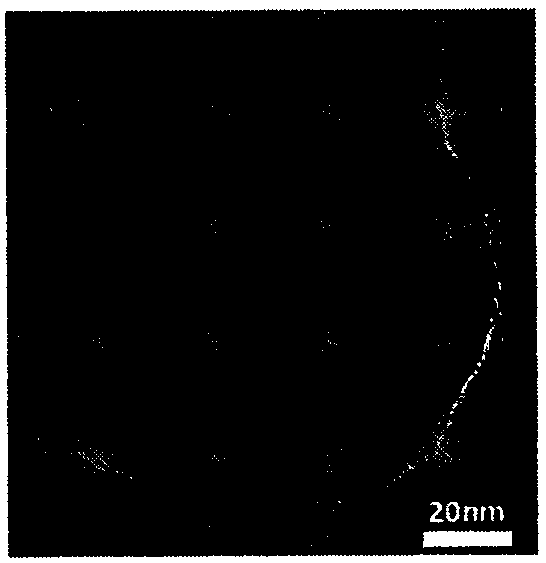

[0029] image 3 The TEM image of the copper / graphene core-shell structure was prepared for this example.

[0030] Figure 4 Prepare the X-ray diffraction pattern of the copper / graphene core-shell structure for this example, wherein the peak p...

Embodiment 2

[0032] (1) Put 0.1g of copper nanospheres with a size of 200-400nm into a CVD tube furnace, the flow rate of hydrogen and argon is 100sccm, the flow rate of acetylene is 5sccm, the temperature is 1000°C, and the time is 45min to form the initial core-shell structure .

[0033] (2) Ultrasonic dispersion of 10 mg of graphene powder with a size of 200-2000 nm in 20 mL of N-methylpyrrolidone, and ultrasonication for 1 h.

[0034] (3) After finishing the ultrasound, quickly add the initial core-shell structure into the solution and stir for 1 hour to obtain the copper / graphene core-shell structure.

Embodiment 3

[0036] (1) Put 0.1g of copper nanospheres with a size of 100-200nm into a CVD tube furnace, the flow rate of hydrogen and argon is 100sccm, the flow rate of ethylene is 5sccm, the temperature is 1000°C, and the time is 45min to form the initial core-shell structure .

[0037] (2) Ultrasonic dispersion of 10 mg of graphene powder with a size of 100-1000 nm in 20 mL of N-methylpyrrolidone, and ultrasonication for 1 h.

[0038] (3) After finishing the ultrasound, quickly add the initial core-shell structure into the solution and stir for 1 hour to obtain the copper / graphene core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com