Iodometric method for determining oxygen vacancy concentration in barium ferrite-based lead-free piezoelectric ceramics

A lead-free piezoelectric and bismuth ferrite technology is used in chemical analysis by titration, which can solve the problems of inaccurate, different, and measurement errors in experimental results, and achieve simple operation steps, easy operation, and simple experimental instruments. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] 1. Preparation of standard samples

[0084] Weigh 0.0564g-3.1447g of bismuth oxide and 0.0194g-1.0778g of iron oxide, add 5mL-280mL of concentrated hydrochloric acid, stir with a magnetic stirrer until completely dissolved, and obtain the required solution.

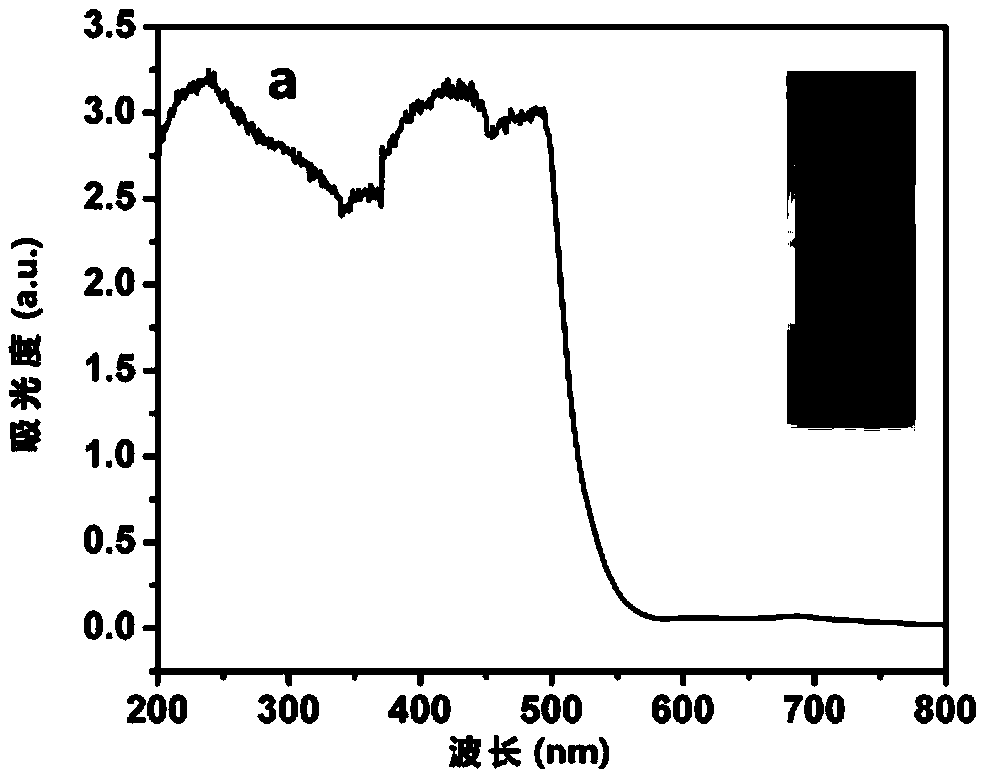

[0085] 2. Determine the color spectrum of the standard sample

[0086] Add 0.1000~5.5557gKI to the solution in step 1, then titrate the sodium thiosulfate standard solution, add starch indicator when the color becomes light, and it is dark blue at this time, continue to titrate the sodium thiosulfate solution, when the blue color disappears, The titration is over. Write down the color change at each stage, and measure the color spectrum at each stage with a spectrophotometer.

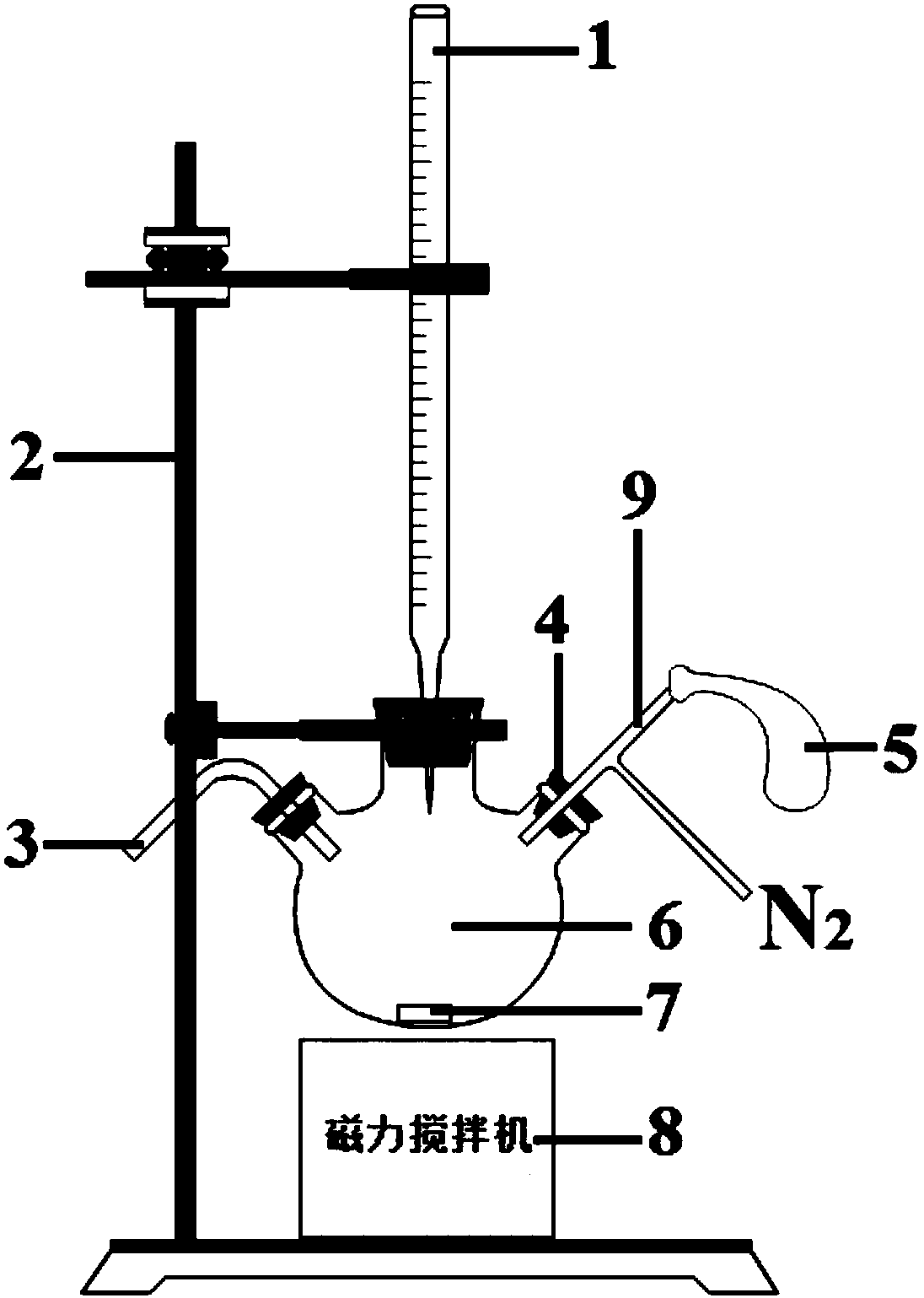

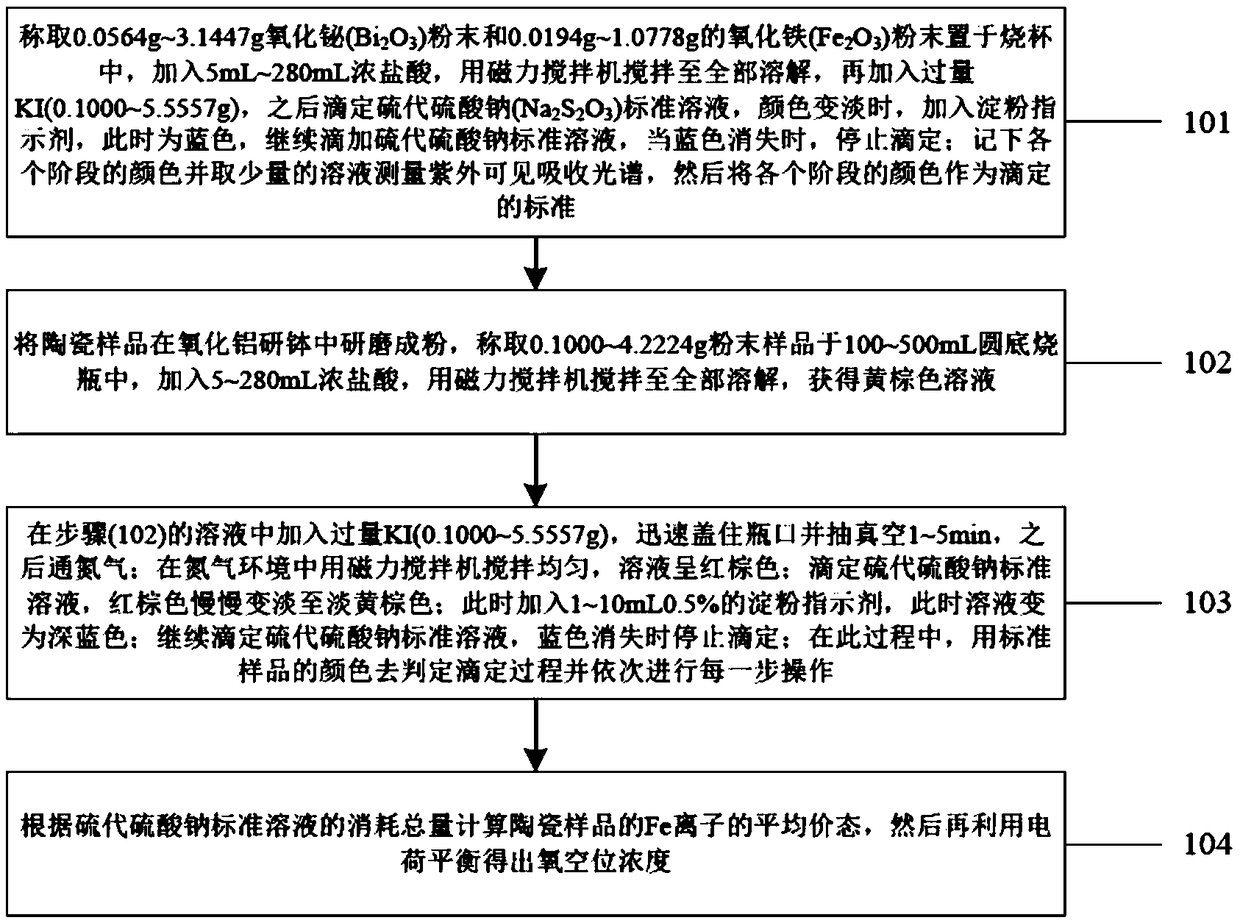

[0087] Such as figure 2 As shown, according to a kind of iodine method for measuring the oxygen vacancy concentration in the bismuth ferrite-based lead-free piezoelectric ceramics according to the present invention, it specifically inclu...

Embodiment 1

[0117] In this embodiment, a set of (1-z) BiFeO 3 -zBaTiO 3 (z=0.20, 0.25, 0.30, 0.35, 0.4) sample as an example, the specific determination method steps are as follows:

[0118] 1. Sample weighing

[0119] Take 0.7BiFeO 3 -0.3BaTiO 3 (z=0.30) ceramic samples were ground into powder with an alumina mortar, and 0.1000 g of powder samples were accurately weighed with an electronic balance.

[0120] 2. Sample dissolution

[0121] Put the weighed powder sample in a 100mL three-neck round-bottomed flask, add 5mL of concentrated hydrochloric acid, and stir with a magnetic stirrer until the bottom of the solution is all white precipitate, which is barium titanate, which is insoluble in concentrated hydrochloric acid. At this time, the solution is Brown yellow, transfer the sodium thiosulfate standard solution to the burette with a pipette, and read the scale number V 1 .

[0122] 3. Sample titration

[0123] Add 0.1000g of potassium iodide to the solution, immediately cover t...

Embodiment 2

[0148] In this embodiment, a set of 0.7Bi(Fe 1-y m y )O 3 -0.3BaTiO 3 (M=Sc; y=0.00, 0.02, 0.04, 0.06, 0.08) sample as an example, the specific determination method steps are as follows:

[0149] 1. Sample weighing

[0150] Take 0.7BiFeO 3 -0.3BaTiO 3 (y=0.00) ceramic samples were ground into powder with an alumina mortar, and 0.6032 g of powder samples were accurately weighed with an electronic balance.

[0151] 2. Sample dissolution

[0152] Put the weighed powder sample in a 100mL three-necked flask, add 30mL of concentrated hydrochloric acid, and stir with a magnetic stirrer until the bottom of the solution is all white precipitate, the white precipitate is barium titanate, which is insoluble in concentrated hydrochloric acid, and the solution is brown at this time , move the sodium thiosulfate standard solution to the burette with a pipette, and read the scale number V 1 .

[0153] 3. Sample titration

[0154] Add 0.6000g of potassium iodide to the solution, imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com