Preparation of compound synergistic wetting agent and its application in aqueous suspension of pymetrozine

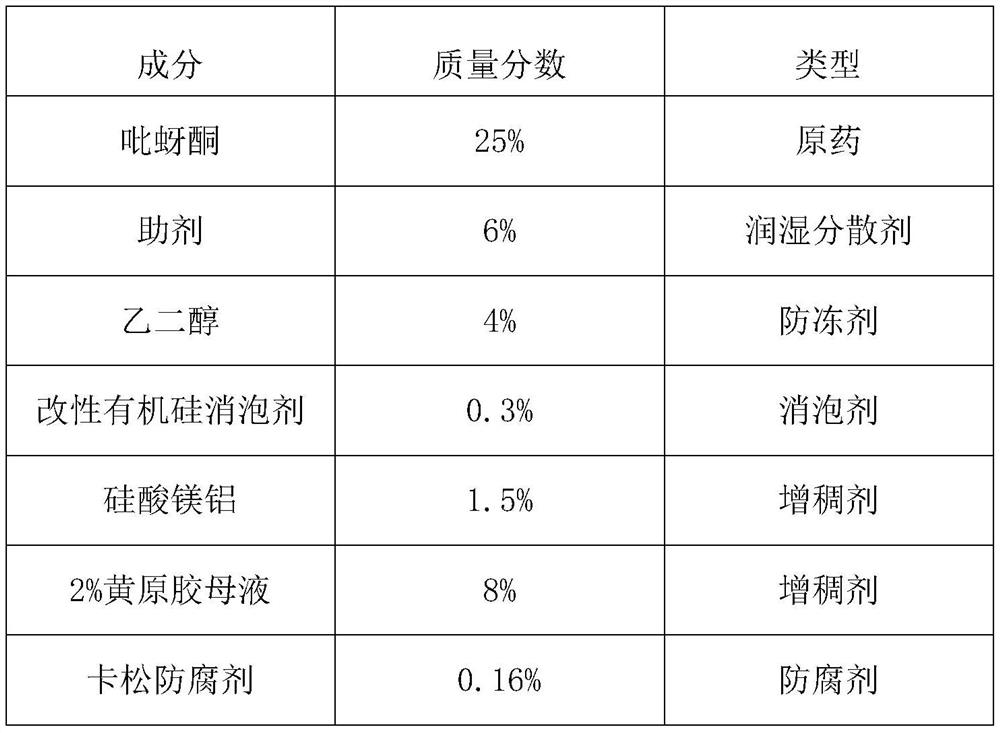

A compound synergistic and wetting agent technology, which is applied in the fields of application, insecticide, biocide, etc., can solve the problem that the pymetrozine aqueous suspension preparation is difficult to make, the pymetrozine suspension has large fluctuations, and the production batch Great impact and other problems, to achieve the effect of excellent stability over time, good steric resistance performance, and no increase in heat storage particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

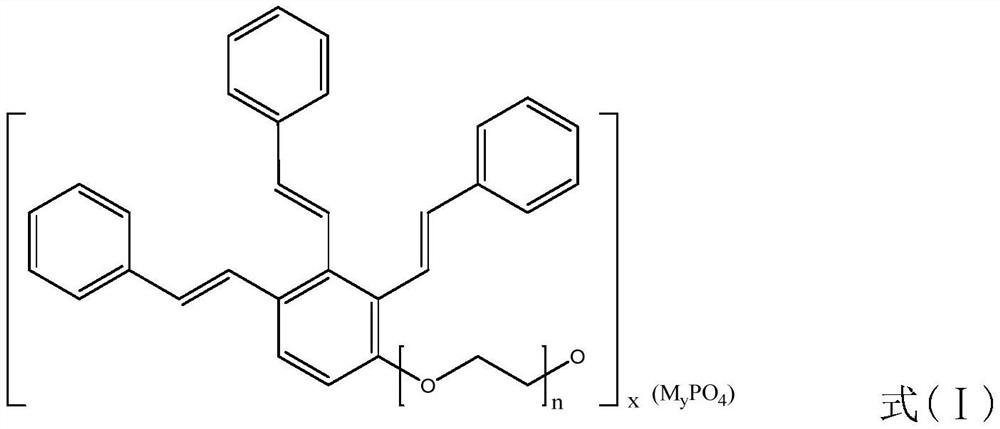

[0053] Example 1 Preparation of Tristyrylphenol Polyoxyethylene Ether Phosphate Salt

[0054] Add 137 parts of tristyrylphenol polyoxyethylene ether (20EO) to a reactor with a thermometer, agitator, reflux pipe, and dropping pipe, and then add 7.1 parts of phosphorus pentoxide, and keep the temperature below 50°C , with mechanical stirring at 200rpm / min, after 4 hours of reaction. Then control the temperature to 90°C, add 5.8 parts of boiling water, keep the temperature at 90°C for 1 hour, then lower the temperature to 30-40°C, add diethanolamine dropwise to adjust the pH value of the reaction product to neutral, and obtain tristyrylphenol polyoxyethylene ether phosphoric acid Ester Salt (A).

Embodiment 2

[0055] The preparation of embodiment dimaleic acid-acrylic acid copolymer sodium salt

[0056] Add 15 parts of maleic acid, 35 parts of methacrylic acid, and 90 parts of deionized water into a reactor with a thermometer, agitator, reflux tube, and dropping tube, and slowly add 30% aqueous sodium hydroxide solution to the pH value Neutral, keep the temperature at 30-50°C, then raise the temperature to 70-80°C, add 1 part of ammonium persulfate initiator, and keep it at 70-80°C for 2 hours to obtain the maleic acid-acrylic acid copolymer sodium salt (B).

Embodiment 6

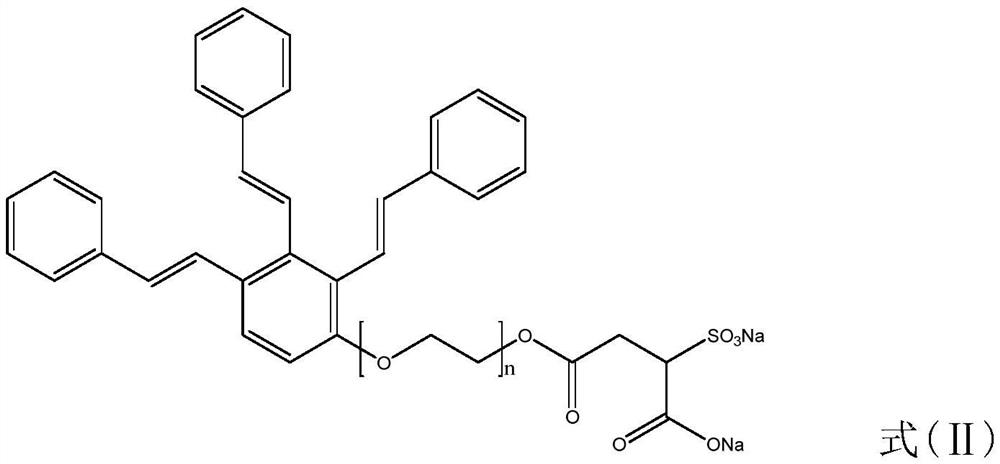

[0057] The preparation of embodiment tristyrylphenol polyoxyethylene ether succinate monoester sulfonic acid sodium salt

[0058] Add 137 parts of tristyrylphenol polyoxyethylene ether (20EO) and 9.8 parts of maleic anhydride to a reactor equipped with a thermometer, agitator, reflux pipe, and dropping pipe, and keep the reaction at 60-65°C for 2 hours, then 12.6 parts of sodium sulfite and 295 parts of deionized water were added, and the reaction was carried out at 60-65° C. for 2 hours to obtain tristyrylphenol polyoxyethylene ether succinate monoester sulfonic acid sodium salt (C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com