Method of using cement kiln intermediate product for harmless disposal of electrolytic manganese slag

A technology of harmless treatment and electrolysis of manganese slag, which is applied in the direction of cement production, treatment of discharged materials, chemical instruments and methods, etc., can solve the problems of high treatment cost, high operation cost, and product frost return, and reduce material transportation cost, reduce the cost of disposal heat energy, and reduce the effect of cement environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

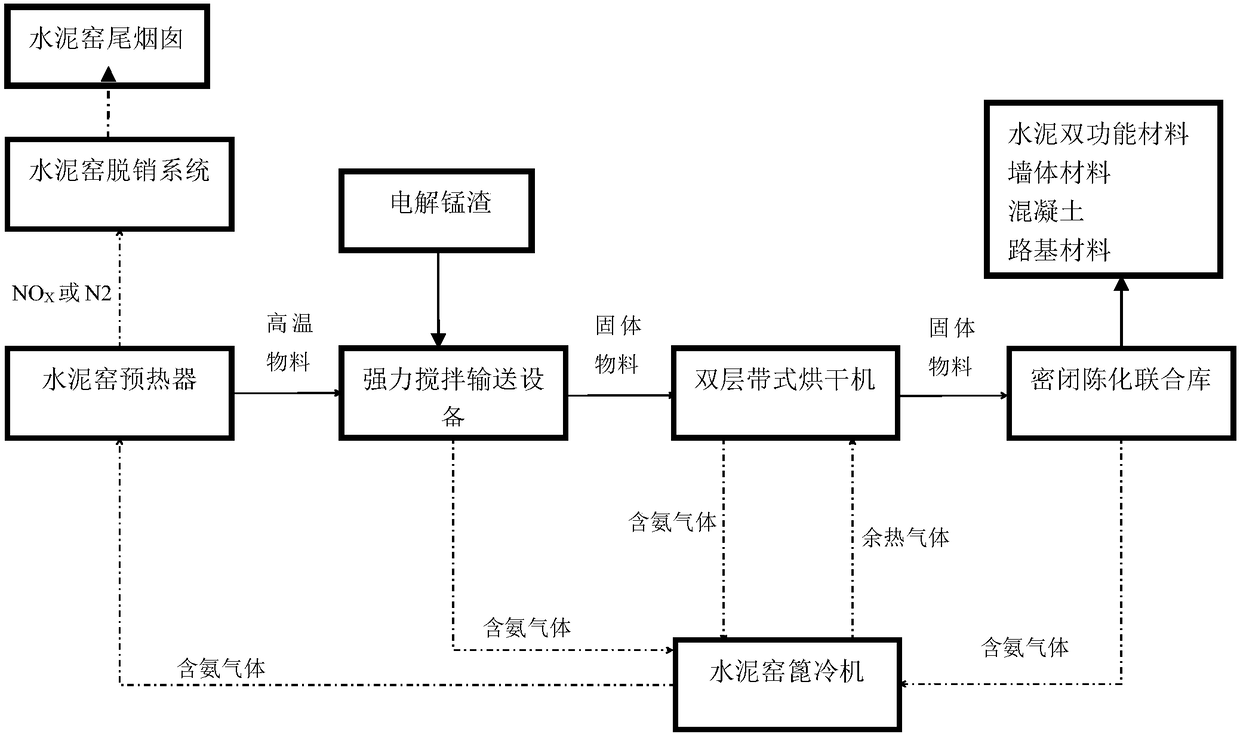

[0042] The method for harmless treatment of electrolytic manganese slag by cement kiln specifically includes the following steps:

[0043] S1 material preparation: During the production process of the cement kiln, 16% of the amount of electrolytic manganese slag is treated in the discharge pipe at the end of the cement kiln every day, and the highly alkaline material (burning raw meal) that replaces the quicklime is taken out and placed in the refractory castable. The raw meal silo is fired, and then it enters the mixing equipment of the S2 link through the conveying device. The high temperature gas (about 1150°C) generated during the material preparation process enters the nearest preheater in the upper part of the cement kiln decomposition furnace with the negative pressure of the cement kiln system. middle;

[0044] S2 Mixing: The electrolytic manganese slag and the alkaline material are mixed in a ratio of 85:15, and sent to the special "strong stirring and conveying equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com