Magnesium-phosphate cementum protection coating for concrete clear water facing and preparing method thereof

A magnesium phosphate cement and protective coating technology, which is applied in the field of building materials, can solve the problem of poor adhesion and volume stability of inorganic Portland cement coatings, and easy aging and volatilization of organic coatings, which affect the environment and human health and other problems, to achieve the effect of solving the surface fouling of concrete structures, improving durability, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

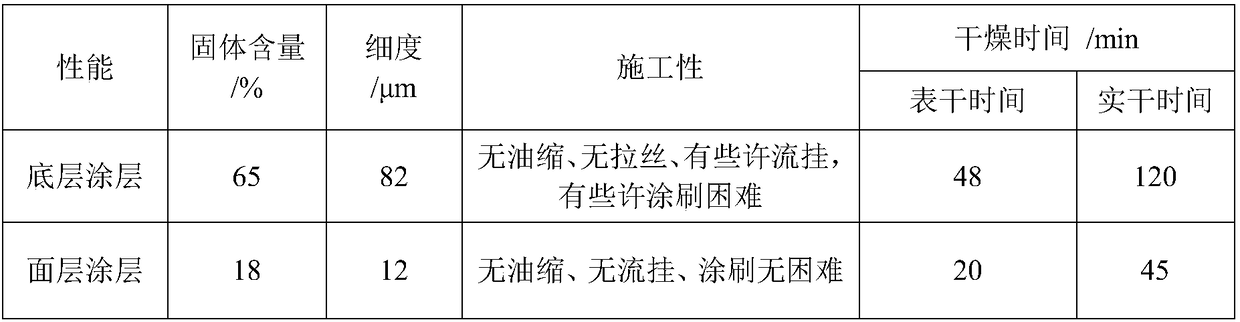

[0026] A magnesium phosphate cementitious protective coating for concrete clear water finish, prepared by the following method:

[0027] 1) The raw material ratio of the bottom coating: the mass ratio of magnesium oxide, potassium dihydrogen phosphate, borax, Portland cement, and fly ash is 57:20:4:4:15, and the content of cellulose ether is all the above materials 0.03% of the total mass, water-solid ratio = 0.3; the surface coating is a silane emulsion, and the mass percentages of each raw material are: 65% of octyltriethoxysilane, 2% of sodium dodecylsulfonate, and the balance is to Ionized water, after mixing the raw material components, was emulsified by ultrasonic (ultrasonic condition: 40kHz×100W, 20min) to prepare silane emulsion;

[0028] 2) Pour the weighed magnesium oxide, potassium dihydrogen phosphate, borax, Portland cement, fly ash and cellulose ether into the mortar mixer and dry mix for 3 to 5 minutes to obtain the concrete clear water facing magnesium phospha...

Embodiment 2

[0046] A magnesium phosphate cementitious protective coating for concrete clear water finish, prepared by the following method:

[0047] 1) Proportion of bottom coating: the mass ratio of magnesium oxide, potassium dihydrogen phosphate, borax, Portland cement, and fly ash is 54:18:4:4:20, and the content of cellulose ether is the total of all the above materials. 0.03% by mass, water-solid ratio = 0.3; the surface coating is silane emulsion, and the mass percentage of each raw material is: octyltriethoxysilane 65%, sodium dodecylsulfonate 2%, and the balance is deionized Water, after mixing the raw material components, using ultrasonic (ultrasonic condition: 40kHz×100W, 20min) emulsification to prepare silane emulsion;

[0048] 2) Pour the weighed magnesium oxide, potassium dihydrogen phosphate, borax, Portland cement, fly ash and cellulose ether into the mortar mixer and dry mix for 3 to 5 minutes to obtain the concrete clear water facing magnesium phosphate cementitious Prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com