Catalyzed synthesis method for anisole

A synthesis method and technology of anisole, which is applied in the field of catalytic synthesis of anisole, can solve the problems of low yield of anisole product, high equipment operation cost, incomplete phenol conversion, etc., so as to facilitate recycling and reuse , energy economy, and the effect of not easy to lose ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

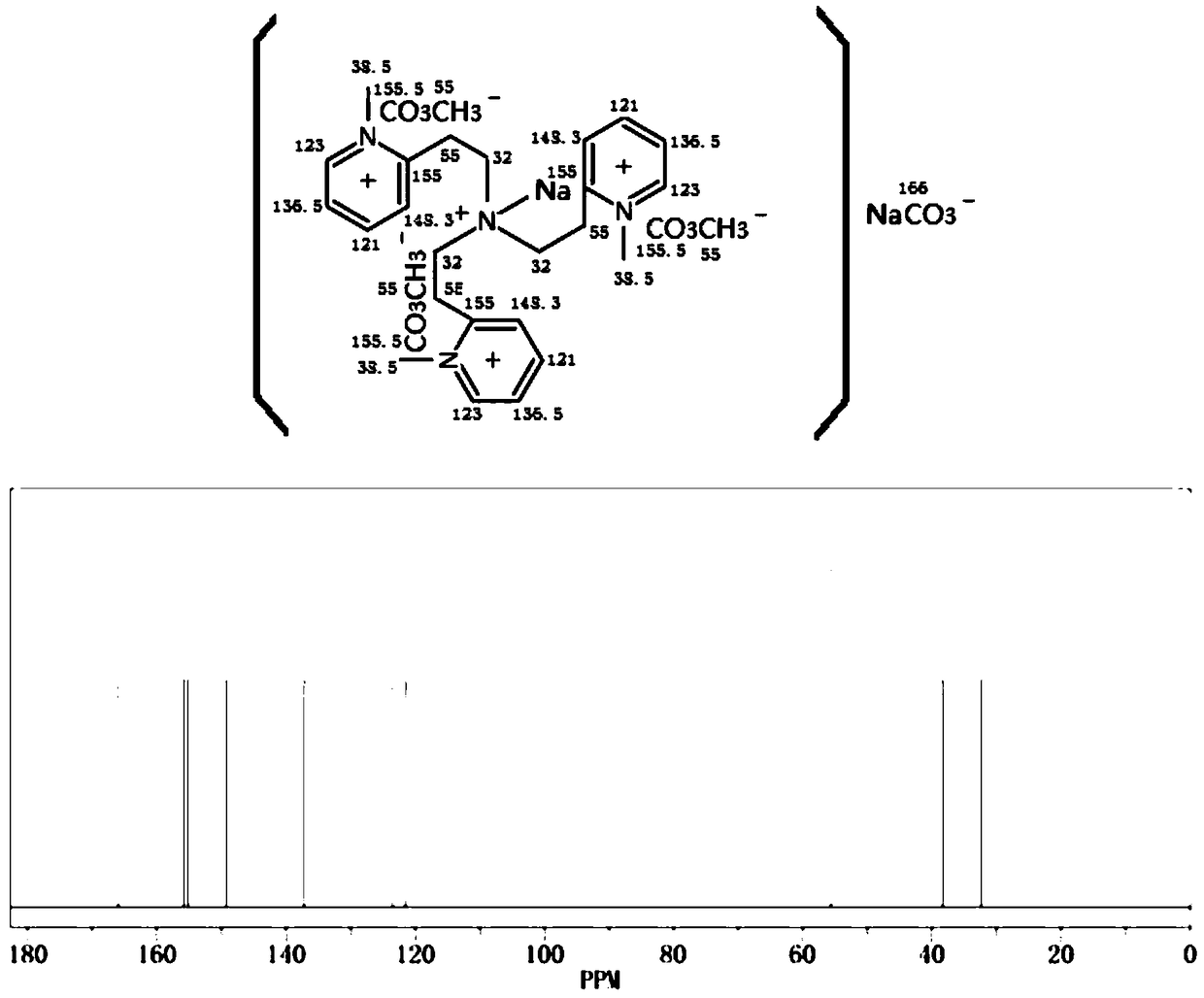

Image

Examples

preparation example Construction

[0036] The preparation condition of table 1 catalyst

[0037]

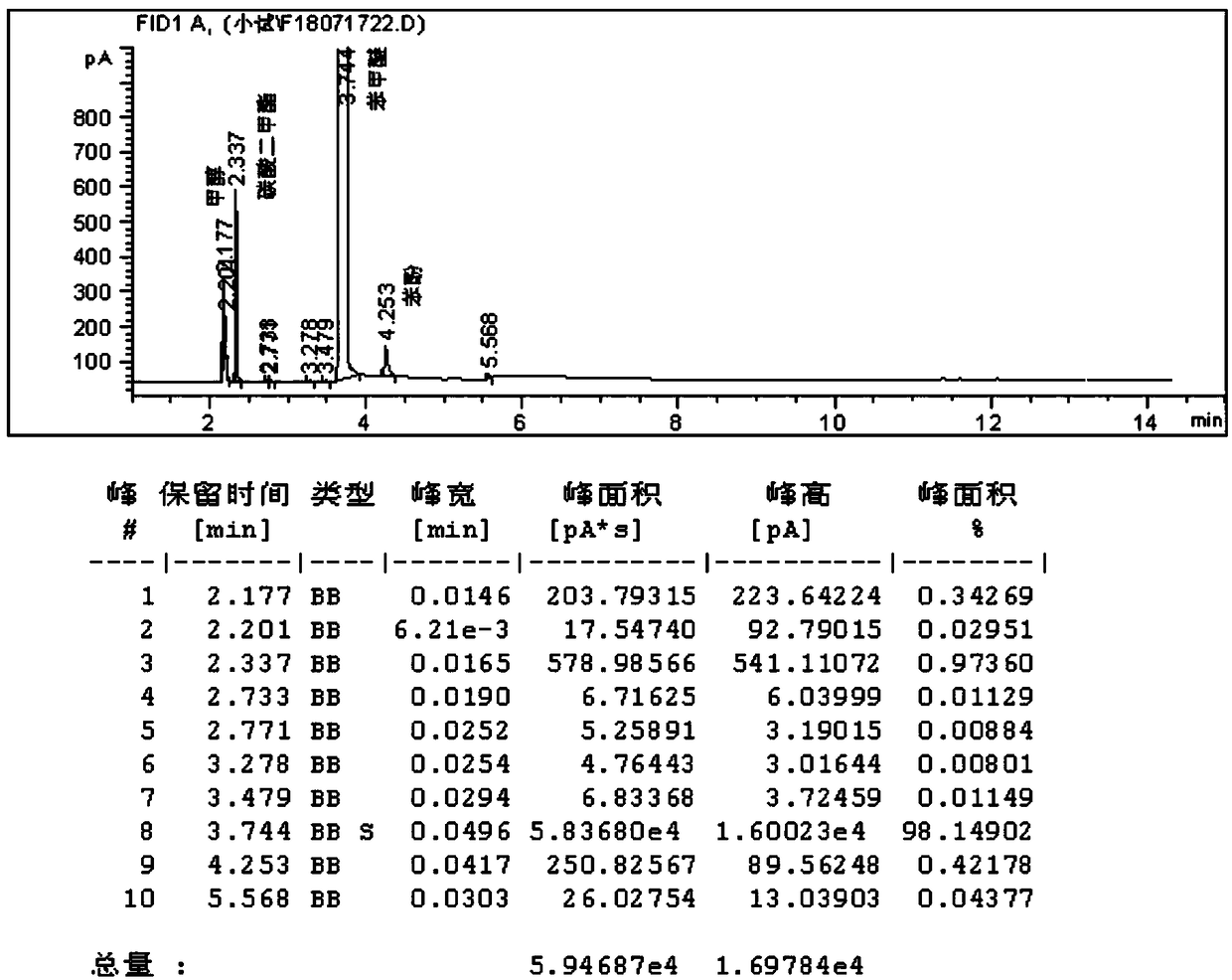

[0038] The embodiment of the present invention uses gas chromatography to detect anisole, and the conditions are as follows:

[0039] GC Agilent 6890 equivalent instrument

[0040] FID detector, chromatography workstation

[0041] ZB-5 (30m×0.32mm×0.25μm) equivalent chromatographic column

[0042] Hydrogen flow rate: 30ml / min

[0043] Air flow rate: 300ml / min

[0044] Carrier gas (high purity nitrogen) flow rate: 1.0ml / min

[0045] Gasification chamber temperature: 260°C

[0046] Detector temperature: 260°C

[0047] Initial column temperature: 100°C

[0048] End column temperature: 280°C

[0049] Heating rate: 30°C / min

Embodiment 1

[0050] The preparation of embodiment 1 anisole

[0051] ① Catalyzed reaction: Put 95g (1mol) of phenol, 190g (2mol) of dimethyl carbonate and 47.5g of No. 1 catalyst into a 0.5L three-necked flask equipped with a thermometer, stirring, fractionating column, condenser and receiving bottle, and stir to raise the temperature Reflux begins to appear at about 90°C. After that, pay attention to controlling the heating rate, and maintain the extraction temperature of the fractionation column at 60-65°C to collect the methanol produced by the reaction. As the reaction continues, the temperature of the kettle will gradually increase. When the temperature reaches 120°C, almost no methanol is produced, and the reaction is nearly complete. A sample from the kettle is taken for gas phase detection and no phenol remains, and the reaction is over.

[0052] ② Recovery of dimethyl carbonate: ① After the reaction, replace the receiving bottle, gradually increase the temperature of the kettle fr...

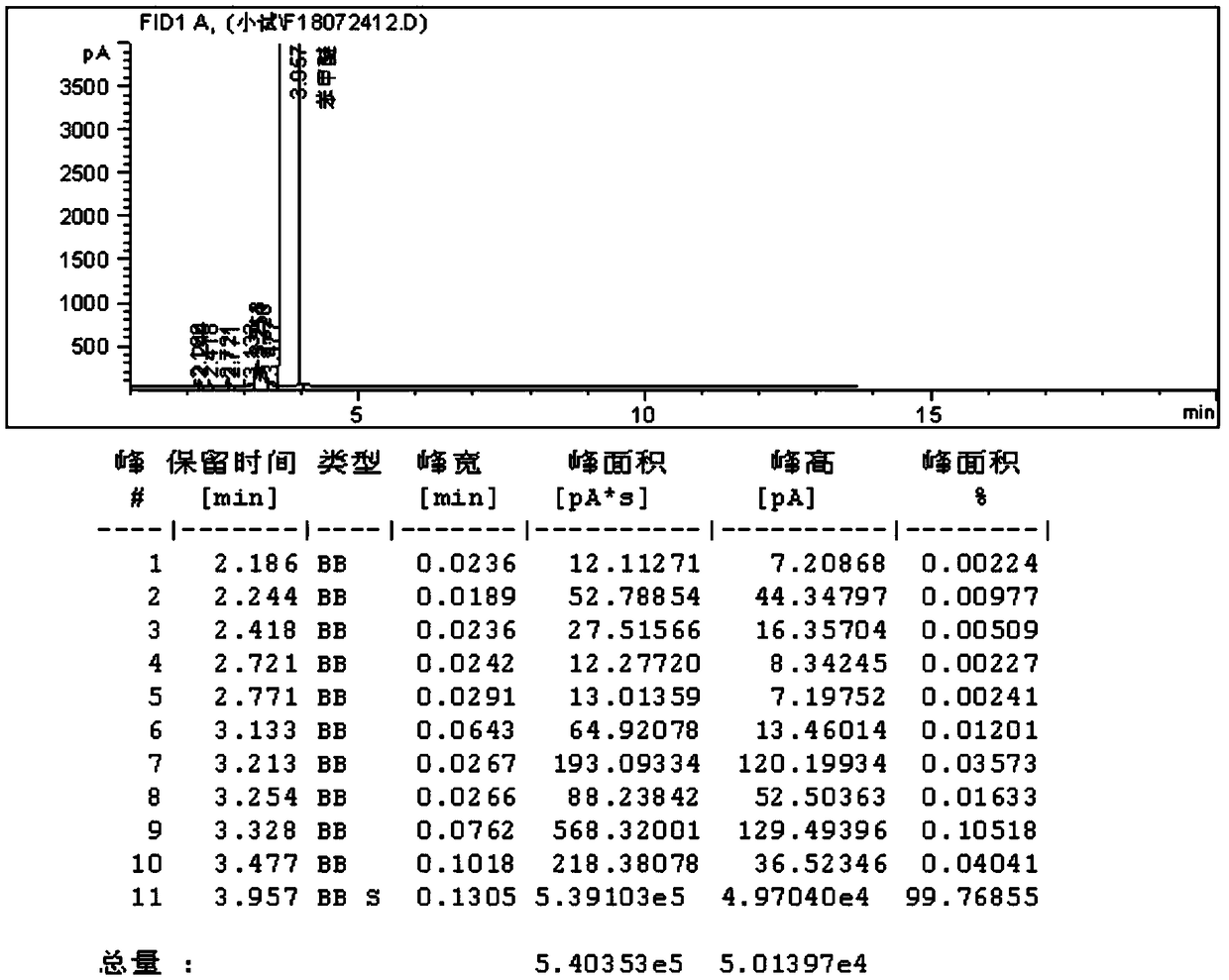

Embodiment 2

[0055] The preparation of embodiment 2 anisole

[0056] Reaction process is with embodiment 1, and difference with embodiment 1 is, in embodiment 1, dimethyl carbonate consumption is changed into 142.5g (1.5mol), replaces No. 1 catalyst with No. 2 catalyst 47.5g simultaneously, other not Change. During the reaction process, the reaction temperature rose up to 130° C., and 49.3 g of the catalyst was recovered after the reaction to obtain 104 g of 99.3% anisole, the product yield was 96.3%, and the distillation residue was 0.9 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com