Preparation method and system for pentaerythritol ester

A pentaerythritol ester and a technology for making pentaerythritol are applied in the field of preparation of pentaerythritol ester, and can solve the problems of increasing operating costs and equipment investment, increasing separation load, harsh reaction conditions and the like, saving equipment investment and operating costs, improving yield, Enhance the effect of esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method and system for preparing pentaerythritol esters.

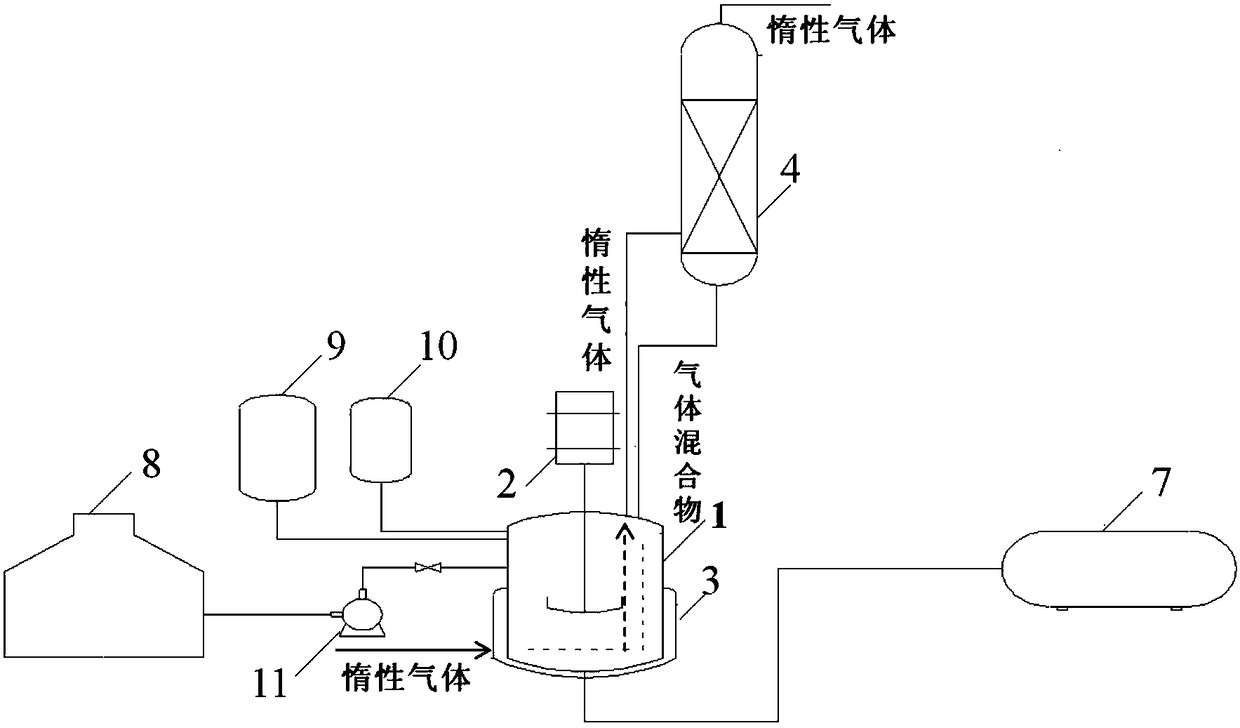

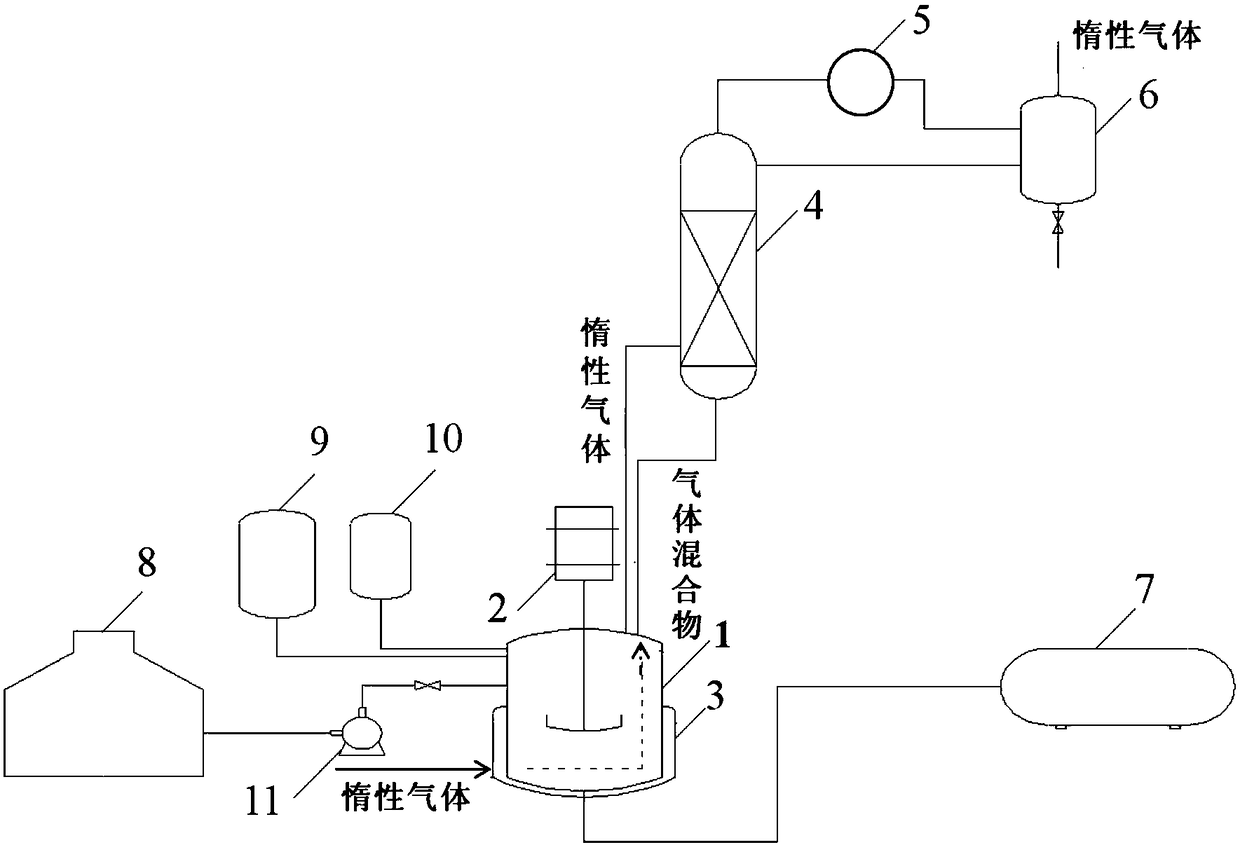

[0056] figure 1 It is a schematic diagram of the system structure for implementing the preparation method of pentaerythritol ester provided by a specific embodiment of the present invention. Such as figure 1 As shown, the system includes a reactive distillation tower, a stirrer 2, a heater 3, a product storage tank 7, a fatty acid storage tank 8, a pentaerythritol storage tank 9, a catalyst storage tank 10, and a feed pump 11.

[0057] Wherein, the above-mentioned reactive distillation tower specifically includes: a tower still 1 and a rectifying section 4, the bottom of the tower still 1 is provided with an air inlet, the top of the tower still 1 is provided with an exhaust port, and the exhaust port is connected with the bottom of the rectifying section 4 The inlet is connected, and the outlet at the bottom of the rectifying section 4 is connected with the inlet at the top of the co...

Embodiment 2

[0064] This embodiment provides a method and system for preparing pentaerythritol esters. Wherein, the system structure is completely consistent with the system in embodiment 1, for details, please refer to figure 1 .

[0065]The specific preparation method of the pentaerythritol ester provided by the present embodiment comprises: at first the mixture of isooctanoic acid and isononanoic acid in the fatty acid storage tank 8 is pumped into the tower kettle 1 by the feed pump 11, and the mixture of the pentaerythritol storage tank 9 Pentaerythritol is added in the tower still 1, and wherein the mol ratio of pentaerythritol, isooctanoic acid and isononanoic acid is 1.0:2.02:2.03; Pass into nitrogen then, make nitrogen enter in the tower still 1 by the gas inlet of tower still 1 bottom and Replace the air present in the tower kettle 1 to ensure that the entire esterification reaction process is carried out under nitrogen protection; then turn on the agitator 2 to mix the isooctan...

Embodiment 3

[0070] This embodiment provides a method and system for preparing pentaerythritol esters. Wherein, the system structure is completely consistent with the system in embodiment 1, for details, please refer to figure 1 .

[0071] The specific preparation method of the pentaerythritol ester provided in this embodiment includes: first adding the mixture of glutaric acid and adipic acid in the fatty acid storage tank 8 to the tower still 1, and adding the pentaerythritol in the pentaerythritol storage tank 9 to the tower still 1 , wherein the molar ratio of pentaerythritol, glutaric acid and adipic acid is 1.0:1.02:1.01; then nitrogen gas is introduced to allow nitrogen to enter the tower kettle 1 through the air inlet at the bottom of the tower kettle 1 and replace it out of the tower kettle 1 Existing air ensures that the entire esterification reaction process is carried out under nitrogen protection; then the agitator 2 is turned on to mix the glutaric acid, adipic acid and pent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com