Photo-curable silk fibroin hydrogel and preparation method thereof

A silk fibroin, light-curing technology, applied in the field of hydrogel materials, can solve the problems affecting the light transmission performance of hydrogels, poor hydrogel resilience, etc., and achieve excellent light transmission performance, high compressive strength, and excellent elasticity. Restorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

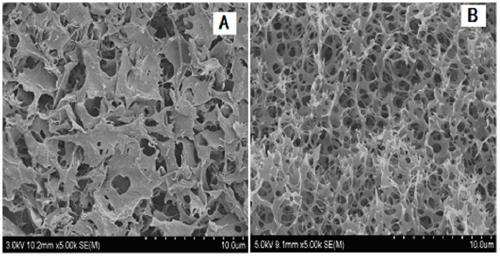

Image

Examples

Embodiment 1

[0021] (1) Preparation of silk fibroin aqueous solution: weigh 3g of anhydrous NaHCO 3 and 1 g anhydrous Na 2 CO 3 Put into boiling 4L deionized water, add 80g silkworm cocoon after fully dissolving, adjust the solution state to slightly boil, stir once every 10 minutes with a glass rod, wash it with deionized water after 30 minutes, repeat the above operation 3 times, each time Weigh new anhydrous NaHCO 3 and anhydrous Na 2 CO 3 ; After fully washing, loosen the silk and put it in a 60°C oven for drying. Take 100ml of 9.3mol / L lithium bromide solution and pour it into a conical flask, heat it to 65°C in a constant temperature magnetic stirrer, add 15g of degummed silk fibroin in several times, and dissolve it at 65±2°C for 30~ After cooling for 40 minutes, take it out, put it in a dialysis bag and seal it, place it in deionized water at low temperature for dialysis for 3 to 4 days, after the dialysis is completed, filter the obtained silk fibroin solution with absorbent ...

Embodiment 2

[0029] (1) Preparation of silk fibroin aqueous solution: weigh 3g of anhydrous NaHCO 3 and 1 g anhydrous Na 2 CO 3 Put into boiling 4L deionized water, add 80g silkworm cocoon after fully dissolving, adjust the solution state to slightly boil, stir once every 10 minutes with a glass rod, wash it with deionized water after 30 minutes, repeat the above operation 3 times, each time Weigh new anhydrous NaHCO 3 and anhydrous Na 2 CO 3 ; After fully washing, loosen the silk and put it in a 60°C oven for drying. Take 100ml of 9.3mol / L lithium bromide solution and pour it into a conical flask, heat it to 65°C in a constant temperature magnetic stirrer, add 15g of degummed silk fibroin in several times, and dissolve it at 65±2°C for 30~ After cooling for 40 minutes, take it out, put it in a dialysis bag and seal it, place it in deionized water at low temperature for dialysis for 3 to 4 days, after the dialysis is completed, filter the obtained silk fibroin solution with absorbent ...

Embodiment 3

[0036] (1) Preparation of silk fibroin aqueous solution: weigh 3g of anhydrous NaHCO 3 and 1 g anhydrous Na 2 CO3 Put into boiling 4L deionized water, add 80g silkworm cocoon after fully dissolving, adjust the solution state to slightly boil, stir once every 10 minutes with a glass rod, wash it with deionized water after 30 minutes, repeat the above operation 3 times, each time Weigh new anhydrous NaHCO 3 and anhydrous Na 2 CO 3 ; After fully washing, loosen the silk and put it in a 60°C oven for drying. Take 100ml of 9.3mol / L lithium bromide solution and pour it into a conical flask, heat it to 65°C in a constant temperature magnetic stirrer, add 15g of degummed silk fibroin in several times, and dissolve it at 65±2°C for 30~ After cooling for 40 minutes, take it out, put it in a dialysis bag and seal it, place it in deionized water at low temperature for dialysis for 3 to 4 days, after the dialysis is completed, filter the obtained silk fibroin solution with absorbent co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com