High-toughness scratch-resistant ABS/PBT alloy and preparation method thereof

A scratch-resistant, high-toughness technology, applied in the field of scratch-resistant ABS/PBT alloy and its preparation, high toughness, can solve the problems of ABS and PBT difficult to dissolve, low impact strength, etc., to improve impact toughness, excellent durability Scratchability, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

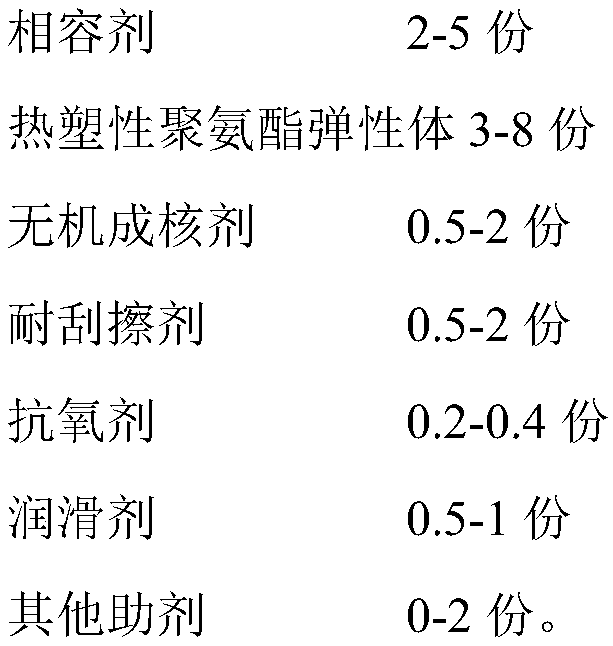

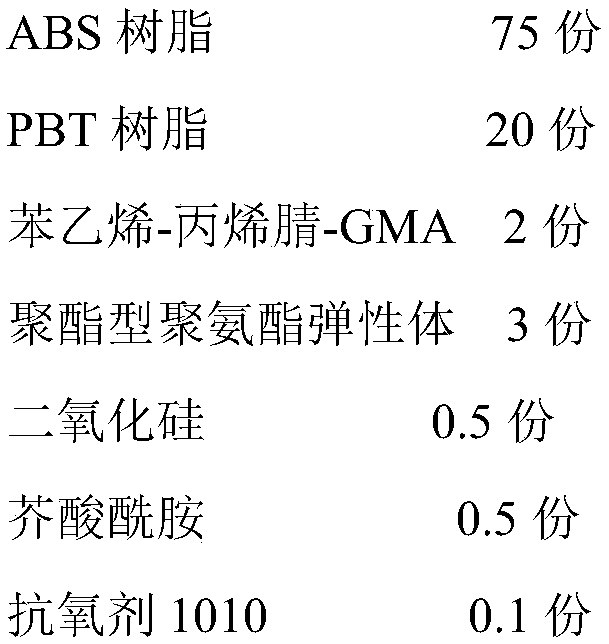

[0027] The high-toughness, scratch-resistant ABS / PBT alloy material in the present embodiment is made up of following raw material according to weight part:

[0028]

[0029]

[0030] Concrete preparation method comprises the following steps:

[0031] (1) Dry the ABS resin in an oven at 80°C for 4 hours, the PBT resin in an oven at 120°C for 4-6 hours, and the TPU elastomer in an oven at 80°C for 2 hours, and control the water content of the three to Below 0.1%, for use.

[0032] (2) 75 parts of ABS resin, 20 parts of PBT resin, 2 parts of styrene-acrylonitrile-GMA, 3 parts of polyester polyurethane elastomer, 0.5 part of silicon dioxide, 0.5 part of erucamide, antioxidant 1010 0.1 1 part, antioxidant 168 0.1 part ethylene bis stearamide 1 part mixed in a high-speed mixer for 10 minutes, put into the main feed of the co-rotating twin-screw extruder, melt extruded and granulated to obtain ABS / PBT Alloy materials; the extrusion temperature of the extruder is 220-240°C, t...

Embodiment 2

[0034] The high-toughness, scratch-resistant ABS / PBT alloy material in the present embodiment is made up of following raw material according to weight part:

[0035]

[0036] Concrete preparation method comprises the following steps:

[0037] (1) Dry the ABS resin in an oven at 85°C for 5 hours, the PBT resin in an oven at 130°C for 5 hours, and the TPU elastomer in an oven at 90°C for 3 hours, and control the water content of the three to 0.1% Below, to be used.

[0038] (2) 62 parts of ABS resin, 30 parts of PBT resin, 3 parts of styrene-acrylonitrile-GMA, 5 parts of polyether polyurethane elastomer, 2 parts of ultrafine barium sulfate, 0.3 parts of erucamide, silicone masterbatch 1 part, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.5 part of ethylene bis stearamide were mixed in a high-speed mixer for 10 minutes, put into the main feed of the co-rotating twin-screw extruder, and melted and extruded , granulation, and obtain the ABS / PBT alloy materia...

Embodiment 3

[0040] The high-toughness, scratch-resistant ABS / PBT alloy material in the present embodiment is made up of following raw material according to weight part:

[0041]

[0042] Concrete preparation method comprises the following steps:

[0043] (1) Dry the ABS resin in an oven at 90°C for 6 hours, the PBT resin in an oven at 140°C for 6 hours, and the TPU elastomer in an oven at 100°C for 4 hours, and control the water content of the three to 0.1% Below, to be used.

[0044] (2) 37 parts of ABS resin, 50 parts of PBT resin, 5 parts of styrene-acrylonitrile-GMA, 8 parts of polyether polyurethane elastomer, 1 part of silicon dioxide, 2 parts of silicone masterbatch, antioxidant DLTP 0.15 parts, 0.15 parts of antioxidant 168, 0.75 parts of pentaerythritol stearate, 0.5 parts of ultraviolet light absorber, 0.5 parts of light stabilizer, 1 part of colorant were mixed in a high-speed mixer for 10 minutes, and put into a co-rotating twin-screw extruder In the main feed, ABS / PBT al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com