A preparation method of inorganic perovskite thin film and application in solar cell

A perovskite and thin film technology, which is applied in the field of inorganic perovskite thin film preparation, can solve the problems of difficult precise control of active layer morphology and band gap, poor spin-coating film spreading, poor repeatability, etc., achieving excellent Reproducibility and effects of increased stability, increased efficiency, increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

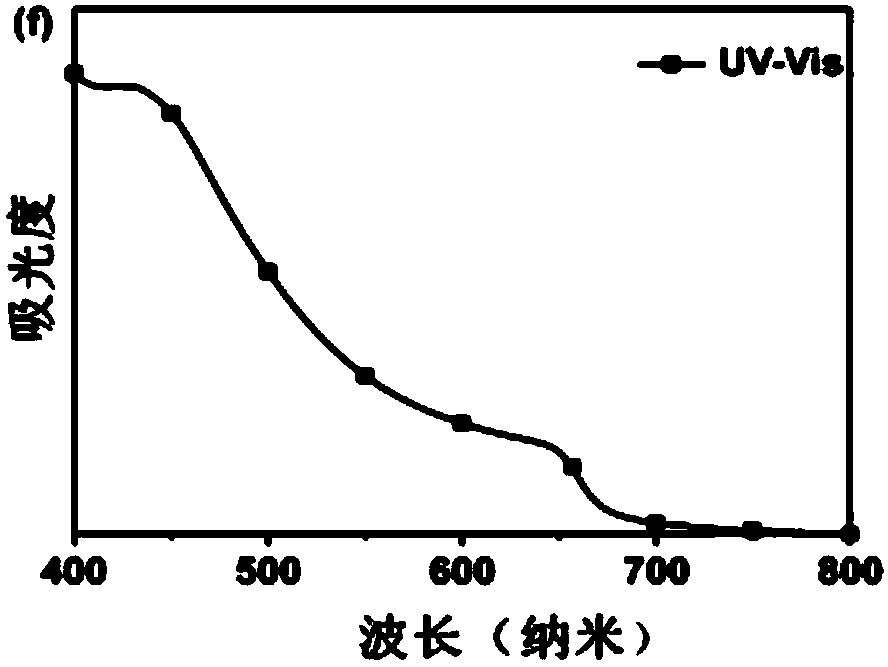

[0035] 1. CsPbI with CsI additive 2 Preparation of Br perovskite solution

[0036] Add 1mmol of lead iodide and 1mmol of cesium bromide into the sample bottle according to the molar ratio of 1:1, then add 1mL of DMSO, put it on a magnetic stirrer, heat and stir at 60°C for 1h, until the solution is completely dissolved, weigh 0.8mmol Excess CsI was added to the solution as an additive, and stirring was continued at 60 °C for 1.5 h to obtain CsPbI containing CsI additive 2 Br perovskite solution.

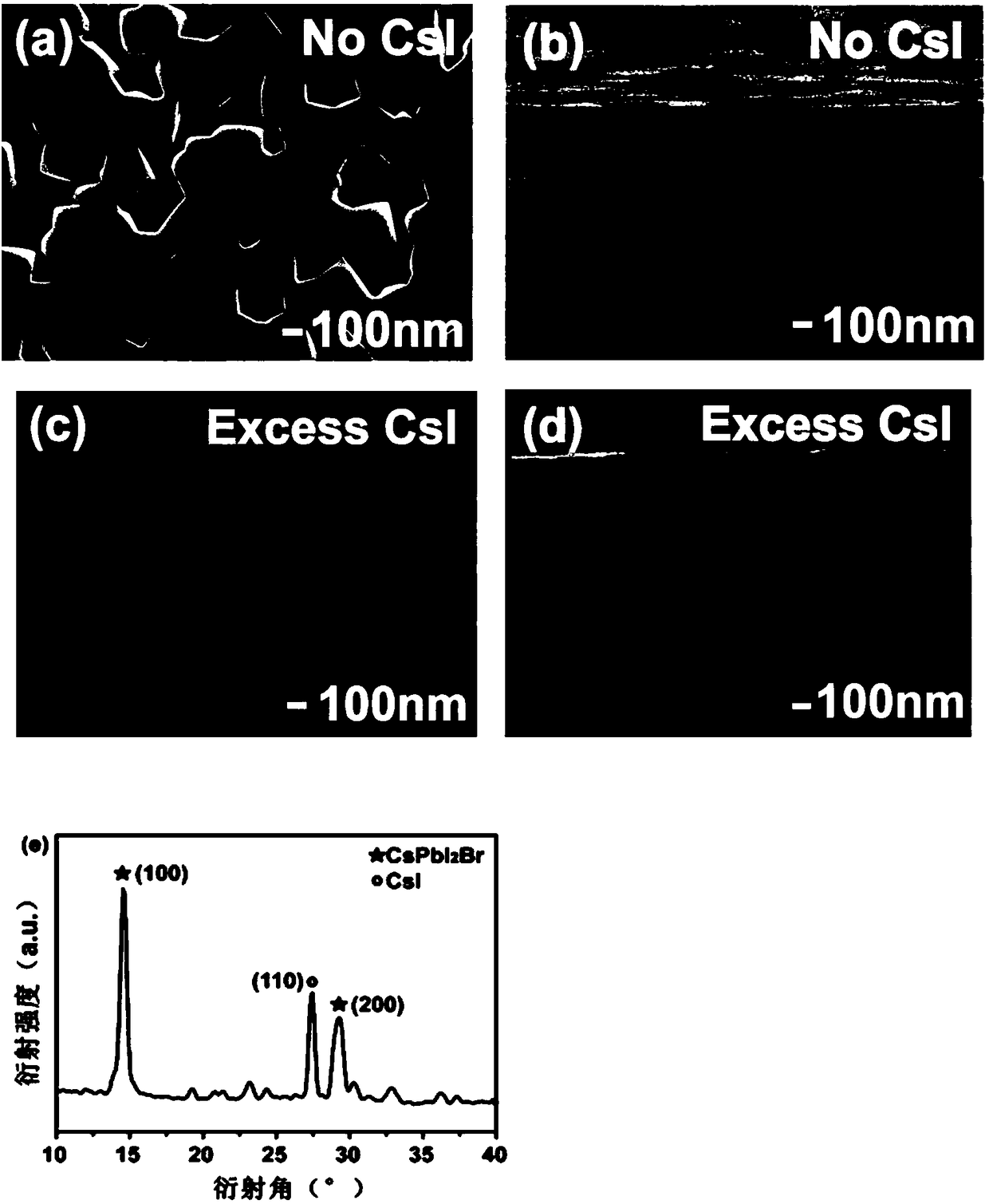

[0037] 2. CsPbI 2 Preparation of Br perovskite thin films

[0038] Spin-coat the perovskite solution prepared in step 1 on the ITO / SnO2 substrate, the spin-coating speed is 1500rpm 10s, 5000rpm 30s, and anti-solvent chlorobenzene is added dropwise in the last sixth second, and then the film is placed on the heating platform for 180 ℃ annealing for 1 min to obtain CsPbI 2 Br perovskite film

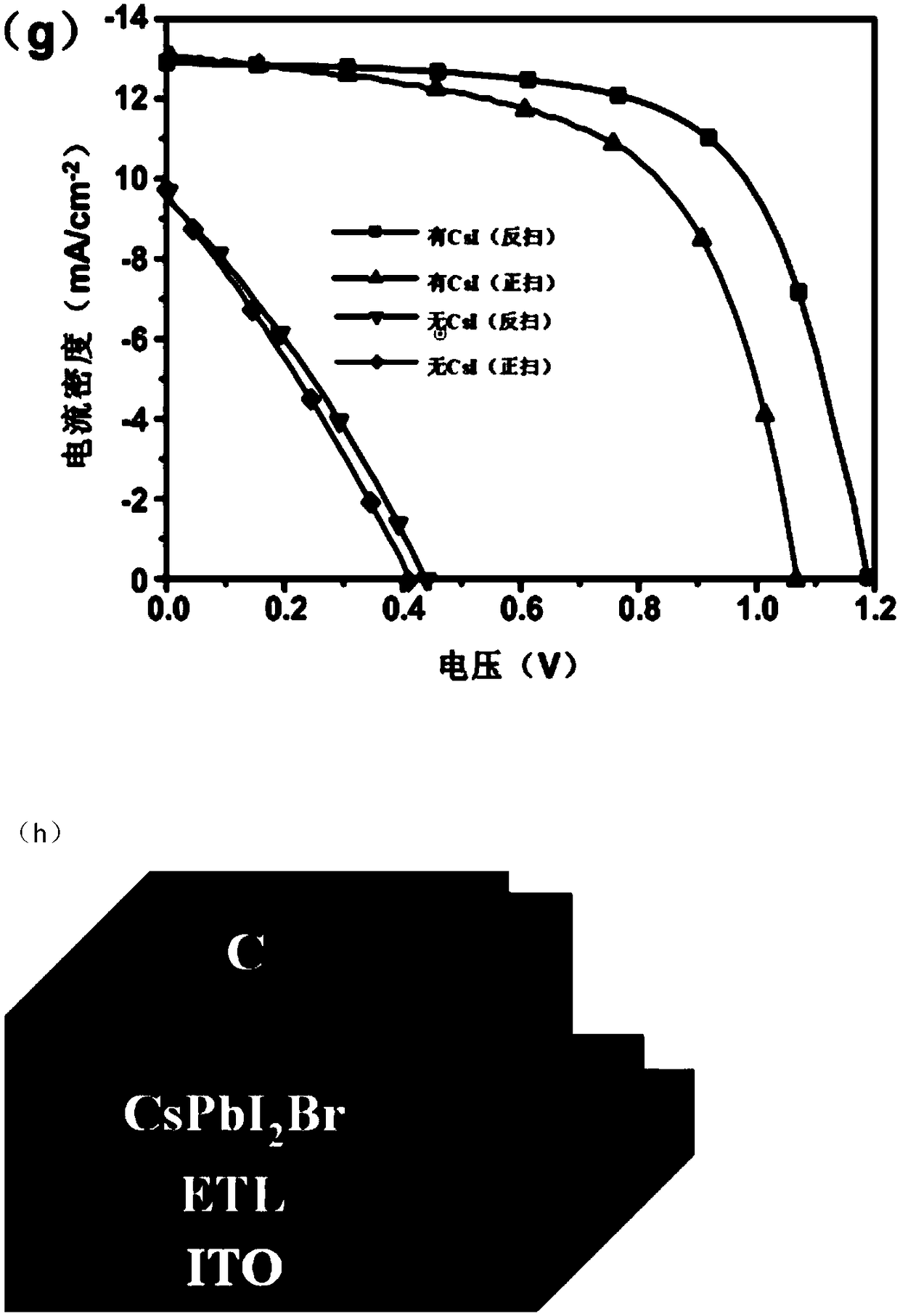

[0039] 3. Preparation of carbon-based inorganic mixed halogen perovskite solar cell dev...

Embodiment 2

[0048] 1. CsPbI with CsI additive 2 The Br perovskite solution was prepared as described in Example 1.

[0049] 2. CsPbI 2 The preparation of Br perovskite thin film is as described in Example 1.

[0050] 3. The preparation of the carbon-based inorganic mixed halogen perovskite solar cell device is as described in Example 1.

[0051] Wherein, the doping amount of CsI is changed to 1 mmol. The open circuit voltage of the obtained device is 1.10, the short circuit current is 14.71, the fill factor is 53.04, and the photoelectric conversion efficiency is 8.59%.

Embodiment 3

[0053] 1. CsPbI with CsI additive 2 The Br perovskite solution was prepared as described in Example 1.

[0054] 2. CsPbI 2 The preparation of Br perovskite thin film is as described in Example 1.

[0055] 3. The preparation of the carbon-based inorganic mixed halogen perovskite solar cell device is as described in Example 1.

[0056] The annealing temperature of the inorganic perovskite film was changed to 150°C for 10 min. The open circuit voltage of the obtained device was 1.13, the short circuit current was 13.45, the fill factor was 63.89, and the photoelectric conversion efficiency was 9.74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com