Technology and system for capturing and preserving carbon dioxide with low energy

A carbon dioxide and low energy consumption technology, applied in the field of high efficiency and low energy consumption flue gas carbon dioxide capture and storage system, can solve the problems of reducing initial investment cost, high energy consumption, and low efficiency, so as to reduce investment cost, improve efficiency, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

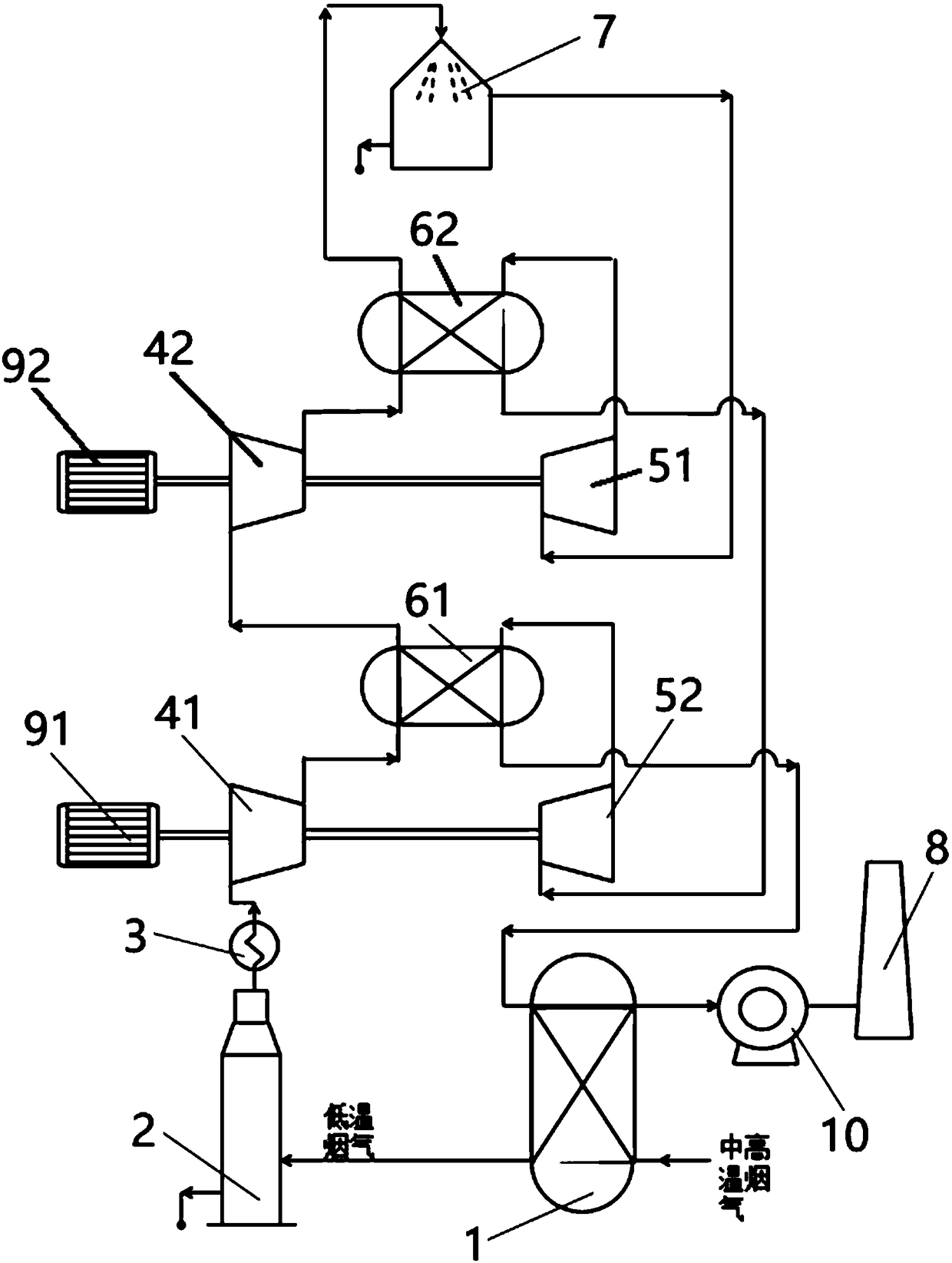

Embodiment 1

[0032] figure 1 It is the schematic diagram of embodiment 1. Such as figure 1 As shown, the low-energy carbon dioxide capture and storage system of the present invention includes a heat recovery heat exchanger 1, a desulfurization and denitrification tower 2, a dryer 3, a compressor unit, an expansion unit, interstage cold regenerators 61, 62, gas-liquid Separation device 7, chimney 8, drive motor 91,92, blower fan 10. Wherein, the compressor unit includes two-stage compressors 41, 42, and the exhaust port and the air inlet of adjacent two-stage compressors 41, 42 are connected through pipelines, and the exhaust pipes of each stage compressor 41, 42 There are one-stage intercooler regenerators 61 and 62 on the road, and the exhaust gases of the compressors 41 and 42 at each stage pass through the hot sides of the corresponding intercooler regenerators 61 and 62 to release heat. The expansion unit includes two-stage expanders 51, 52, the exhaust port and the intake port of t...

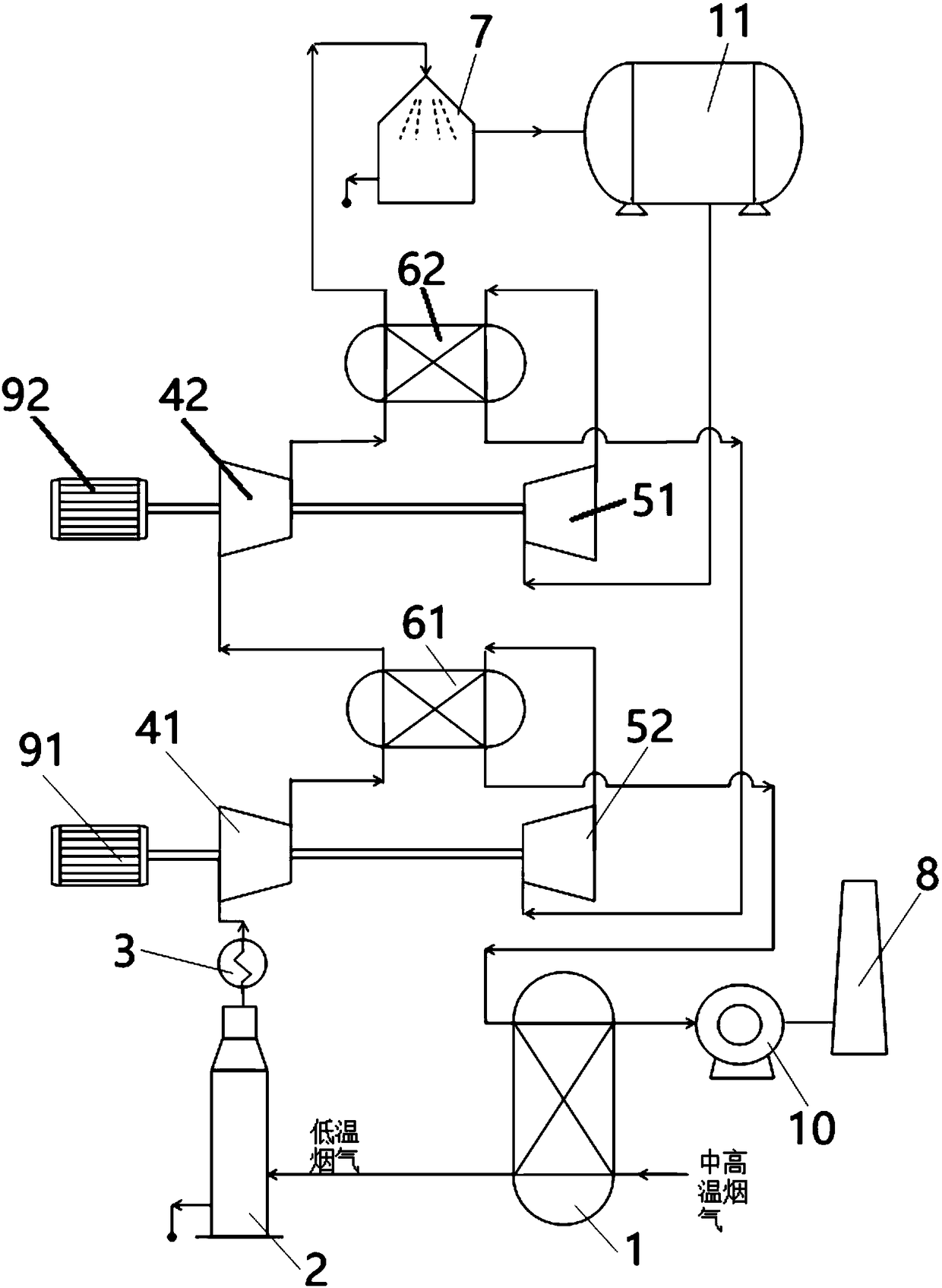

Embodiment 2

[0036] figure 2 It is the schematic diagram of embodiment 2. The difference from Embodiment 1 is that a compressed gas storage tank 11 is arranged on the communication pipeline between the high-pressure gas outlet of the gas-liquid separation device 7 and the air inlet of the first-stage expander 51, and each intercooler 61, 62 is a heat storage type intercooler. The high-pressure gas from which carbon dioxide has been removed can be temporarily stored in the compressed gas storage tank 11 to form an energy storage system. When the power is surplus at night, the drive motor is used to compress the flue gas and store the high-pressure gas. During the day, the high-pressure gas is released to drive the expander to replace the drive. The motor compresses the flue gas, or is used to drive other power and power generation equipment to play a role in peak regulation. For systems with compressed gas storage tanks, cold air cannot be supplied at any time after expansion, and the in...

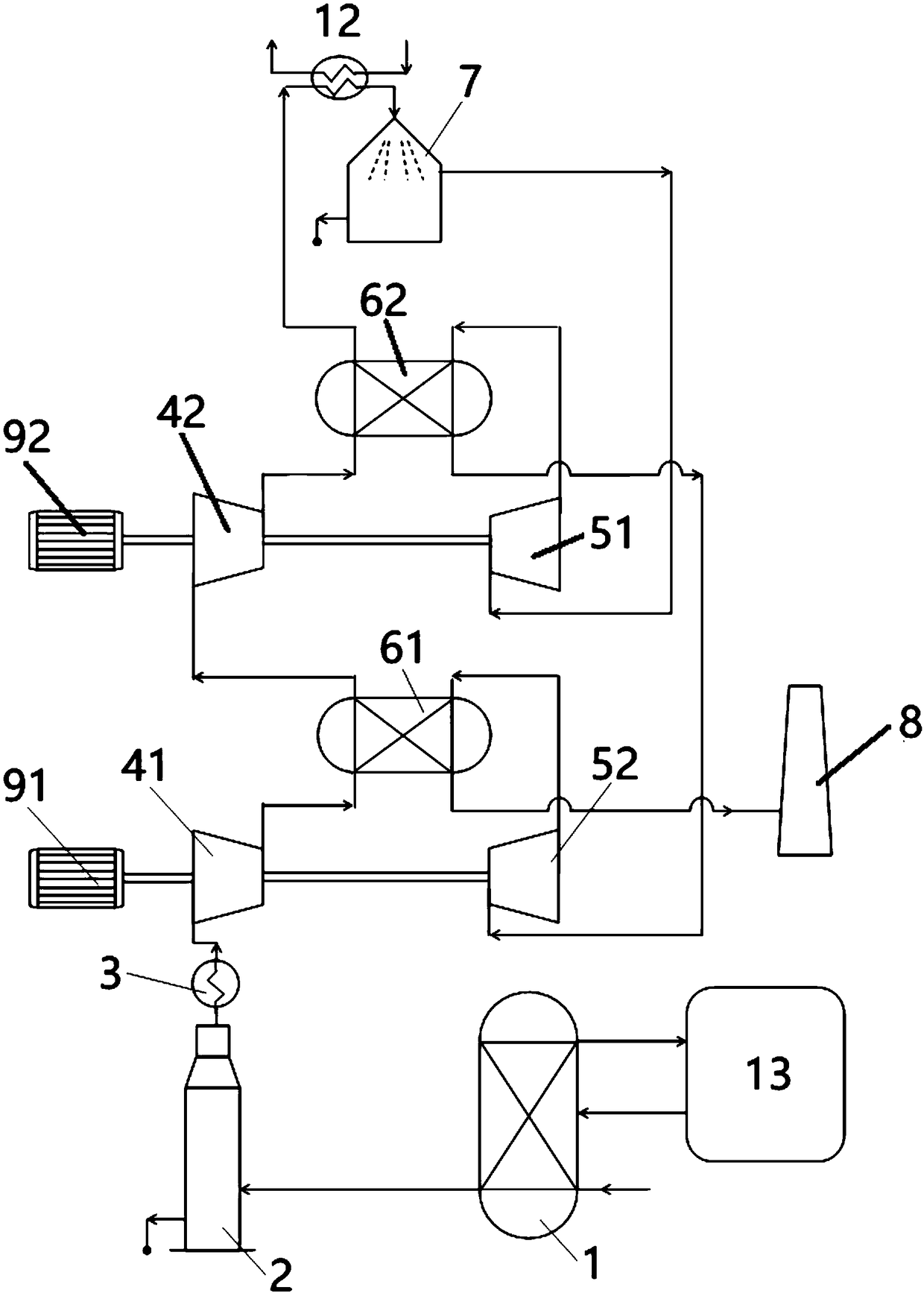

Embodiment 3

[0038] image 3 It is the schematic diagram of embodiment 3. Different from Embodiment 1, a water-cooled heat exchanger 12 is provided on the inlet pipeline of the gas-liquid separation device 7, and the exhaust port of the last stage expander 52 passes through the cold side of the first interstage cold regenerator 61 and then connects with the The flue gas discharge tower 8 is connected, and the cold side of the heat recovery heat exchanger 1 is connected with an absorption chiller 13 , and the cold water produced by the absorption chiller 13 is passed into the cold side of the water-cooled heat exchanger 12 . For natural gas boilers, boilers operating in summer, etc., the flue gas can be discharged at low temperature, so it is not necessary to reheat before discharge. After entering the water-cooled heat exchanger 12, it is used to further cool the high-pressure flue gas passed into the gas-liquid separation device 7, so as to improve the carbon dioxide capture effect. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com