Preparation method for automobile seat sponge

A car seat and sponge technology, applied in the field of decorative materials, can solve problems such as damage to health, insufficient support, and highly toxic raw materials, and achieve high cell uniformity, high porosity, and easy control of cell structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

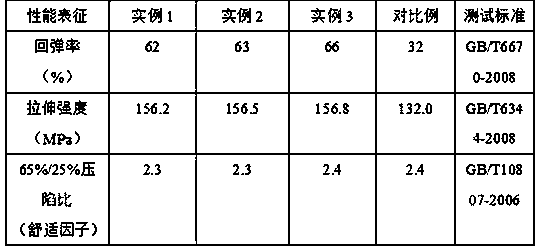

Examples

example 1

[0021] According to the mass ratio of 1:5, EPDM rubber and 200# solvent oil were mixed and stirred evenly to obtain the sol. In parts by weight, 10 parts of the sol, 5 parts of methyl hydrogen-containing silicone oil, 0.2 parts of platinum catalyst, 0.1 part of polyethylene glycol, 1 part of Span-80, 6 parts of cyclohexane, methyl hydrogen-containing silicone oil, platinum catalyst and polyethylene glycol were added to the sol, and after stirring evenly, a mixed sol was obtained, and the Span-80 Dissolve in cyclohexane to obtain an oil phase. Add the mixed sol to the oil phase and mix evenly at an emulsification rate of 8000r / min to obtain an emulsion. Add the emulsion dropwise to the liquid silicone rubber at a stirring rate of 600r / min and stir evenly The complex phase emulsion was obtained, kept at 40°C for 1h, centrifuged to separate the product, washed with water and ethanol three times, added accelerator TMTD, vulcanized at a temperature of 110°C and a pressure of 0.4MPa,...

example 2

[0023]According to the mass ratio of 1:5, EPDM rubber and 200# solvent oil were mixed and stirred evenly to obtain the sol. In parts by weight, 14 parts of the sol, 6 parts of methyl hydrogen silicone oil, 0.25 parts of platinum catalyst, 0.15 parts of polyethylene glycol, 1.5 parts of Span-80, 9 parts of cyclohexane, methyl hydrogen-containing silicone oil, platinum catalyst and polyethylene glycol were added to the sol, and after stirring evenly, a mixed sol was obtained, and the Span-80 Dissolve in cyclohexane to obtain an oil phase. At an emulsification rate of 9000r / min, add the mixed sol to the oil phase and mix evenly to obtain an emulsion. At a stirring rate of 700r / min, add the emulsion dropwise to the liquid silicone rubber and stir evenly The complex phase emulsion was obtained, kept at 40°C for 1 hour, centrifuged to separate the product, washed with water and ethanol four times, added accelerator TMTD, vulcanized at a temperature of 140°C and a pressure of 0.5MPa, ...

example 3

[0025] According to the mass ratio of 1:5, EPDM rubber and 200# solvent oil were mixed and stirred evenly to obtain the sol. In parts by weight, 18 parts of the sol, 7 parts of methyl hydrogen-containing silicone oil, 0.3 parts of platinum catalyst, 0.2 parts of polyethylene glycol, 2 parts of Span-80, 12 parts of cyclohexane, methyl hydrogen-containing silicone oil, platinum catalyst and polyethylene glycol were added to the sol, and after stirring evenly, a mixed sol was obtained, and the Span-80 Dissolved in cyclohexane to obtain an oil phase, at an emulsification rate of 10000r / min, add the mixed sol to the oil phase and mix evenly to obtain an emulsion, at a stirring rate of 800r / min, add the emulsion dropwise to the liquid silicone rubber, and stir evenly The complex phase emulsion was obtained, kept at 40°C for 1h, centrifuged to separate the product, washed with water and ethanol for 5 times, added accelerator TMTD, vulcanized at a temperature of 170°C and a pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com