Preparation and application of flower-shaped molybdenum disulfide coated spherical sisal carbon electrode material

A molybdenum disulfide, spherical technology, applied in the field of electrochemical electrode materials, biomass materials and inorganic materials molybdenum disulfide, can solve the problem of low specific capacity of sisal fiber carbon, poor conductivity of molybdenum disulfide, and poor structural stability and other problems, achieve good conductivity, low cost, and solve the effect of poor conductivity of flower-shaped molybdenum disulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] (1) Weigh 3 g of washed and dried sisal fiber, cut it into 2-3 cm thin sections with scissors, and put it into a polytetrafluoroethylene reaction kettle. Add 70mL of hydrochloric acid solution with a concentration of 4mol / L, put it in a blast oven at 160°C for 10 hours, cool to room temperature, filter with deionized water and absolute ethanol solution until the pH becomes neutral. Finally, it was dried in an oven at 80° C. for 12 hours to obtain a pre-product 1 .

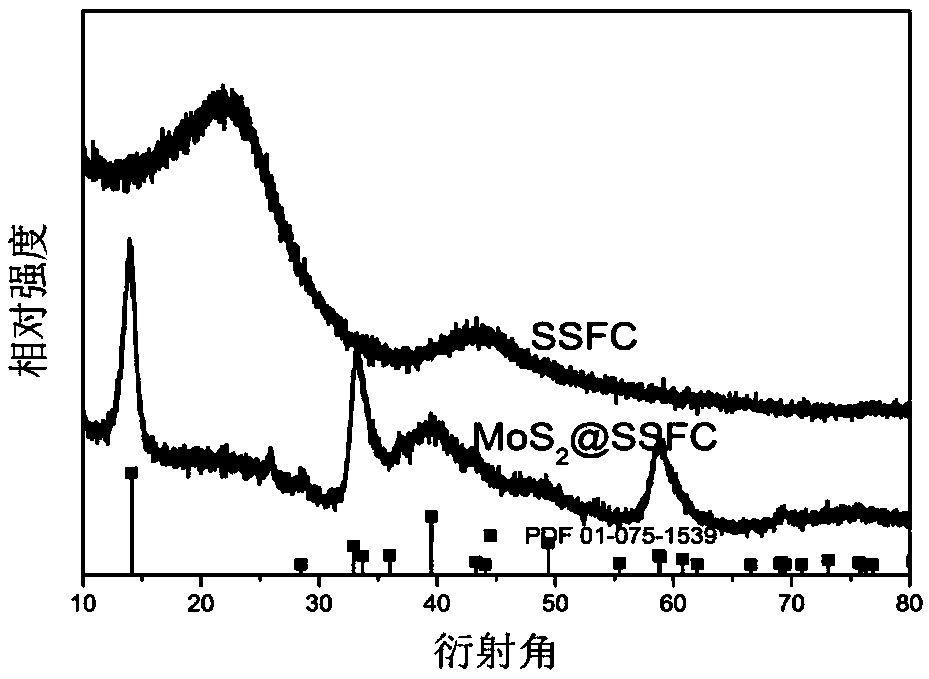

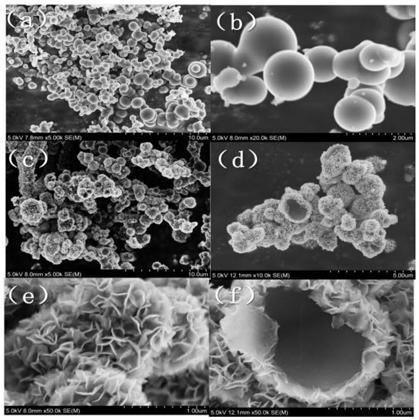

[0028](2) Put the pre-product obtained in step (1) into a nitrogen tube furnace, set the gas flow rate at 60mL / min and the heating rate at 3°C / min, and calcinate to 700°C, and the holding time is 1 hour . After cooling to room temperature, spherical sisal charcoal (SSFC) is obtained, which has a solid spherical structure, a size between 1 and 3 μm, and a smooth surface without impurities.

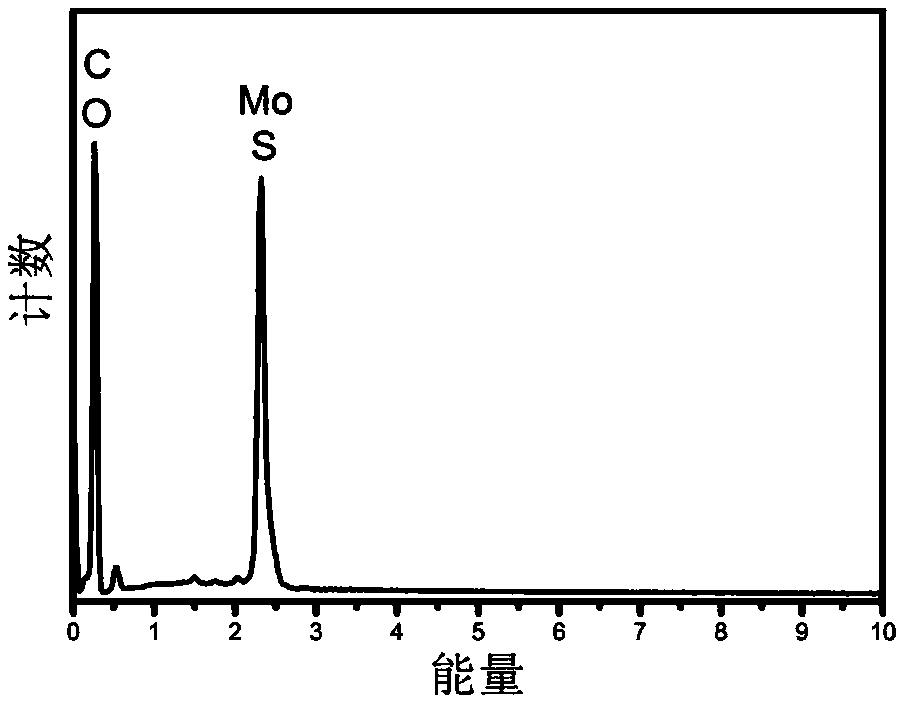

[0029] (3) First weigh 0.3g of the SSFC obtained in step (2) and put it into a polytetrafluoroethylene reactor, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com