A nano-flower spherical cobalt disulfide composite material and a preparation method thereof

A cobalt disulfide, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor long-term cycle performance of batteries and complicated preparation procedures, and achieve enhanced electrochemical performance. , The preparation method is simple, and the effect is conducive to infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of a nano flower spherical cobalt disulfide composite material, comprising: S1) mixing an organic acid cobalt salt, an organic sulfur source and a glycol solvent, and obtaining an intermediate product after a hydrothermal reaction; the organic The sulfur source contains amino groups; S2) The intermediate product is mixed with sulfur powder, and annealed in a protective atmosphere to obtain a nano flower spherical cobalt disulfide composite material.

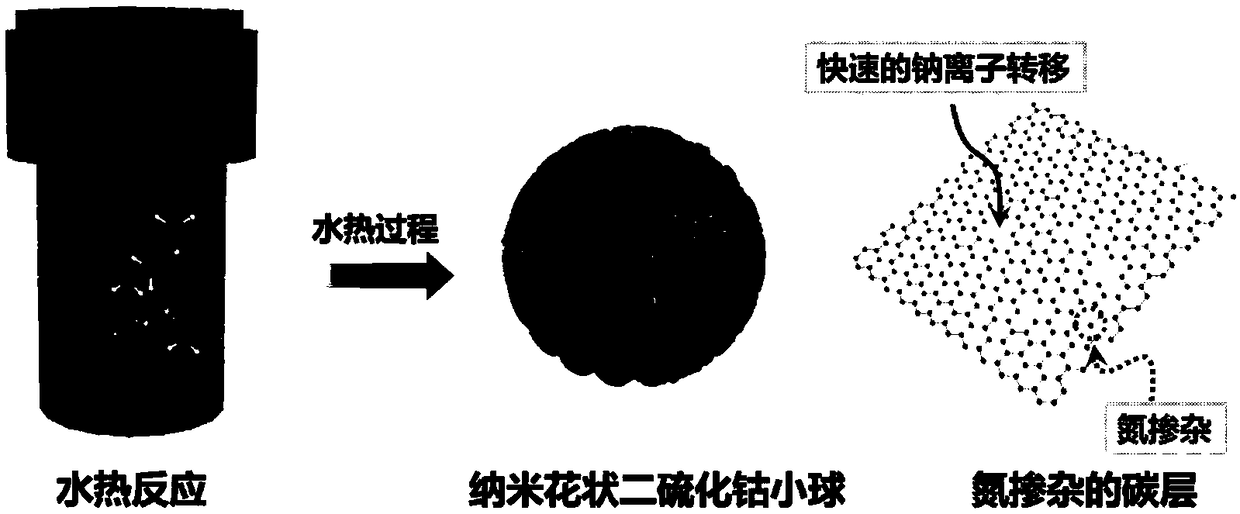

[0034]see figure 1 , figure 1 It is a schematic diagram of the synthesis of the nanoflower spherical cobalt disulfide composite material provided by the present invention, which utilizes hydrothermal reaction self-assembly to form the nanoflower spherical cobalt disulfide composite material.

[0035] The preparation method of the invention is simple, the cycle is short and the efficiency is high. In this method, only one step of hydrothermal self-assembly is required to form th...

Embodiment 1

[0051] Mix 3.0g of cobalt oxalate tetrahydrate and 1.04g of thiourea into a beaker filled with 70ml of ethylene glycol and stir in a water bath. The temperature of the water bath is 45°C and the stirring time is 15 minutes; The stainless steel reaction kettle was sealed, and then the stainless steel reaction kettle was placed in a blast oven at 180°C and kept at a constant temperature for 12 hours.

[0052] After the reaction, take out the suspension in the reaction kettle, wash it with ethanol, then centrifuge the suspension, set the centrifugal speed to 10000r / min, and the centrifugation time is 20min; put the separated solid precipitate into In a vacuum oven at 50° C., take it out after baking for 10 hours to obtain an intermediate product.

[0053] Take 2g of the intermediate product, mix it with 2g of sulfur powder, and put it into a tube furnace for annealing. The atmosphere in the tube furnace is argon, the heating rate of the annealing treatment is 5°C / min, the holdin...

Embodiment 2

[0057] Take 3.0g of cobalt oxalate tetrahydrate and 1.04g of thiourea and mix them into a beaker filled with 50ml of ethylene glycol for stirring in a water bath. The temperature of the water bath is 45°C and the stirring time is 15 minutes. Pour the homogeneous solution after mixing and dissolving into a stainless steel reaction kettle and seal it, then put the stainless steel reaction kettle into a blast oven at 180°C, and place it at a constant temperature for 6h.

[0058] After the reaction, the suspension in the reactor was taken out, washed twice with water, and then washed twice with ethanol. The suspension was centrifuged, the centrifugation speed was set to 10000r / min, and the centrifugation time was 20min. The separated solid precipitate was put into a vacuum oven at 50° C., baked for 10 h, and then taken out to obtain an intermediate product.

[0059] Take 2g of the intermediate product, mix it with 3g of sulfur powder, and put it into a tube furnace for annealing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com