Carbon-based metal catalyst and preparation method and application thereof

A metal catalyst and metal-based technology, which is applied in the field of carbon-based metal catalysts and their preparation, can solve the problems of low loading, low dispersion, and inability to remove gaseous benzene pollutants, etc., and achieve high loading and simple preparation process , easy to operate and promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

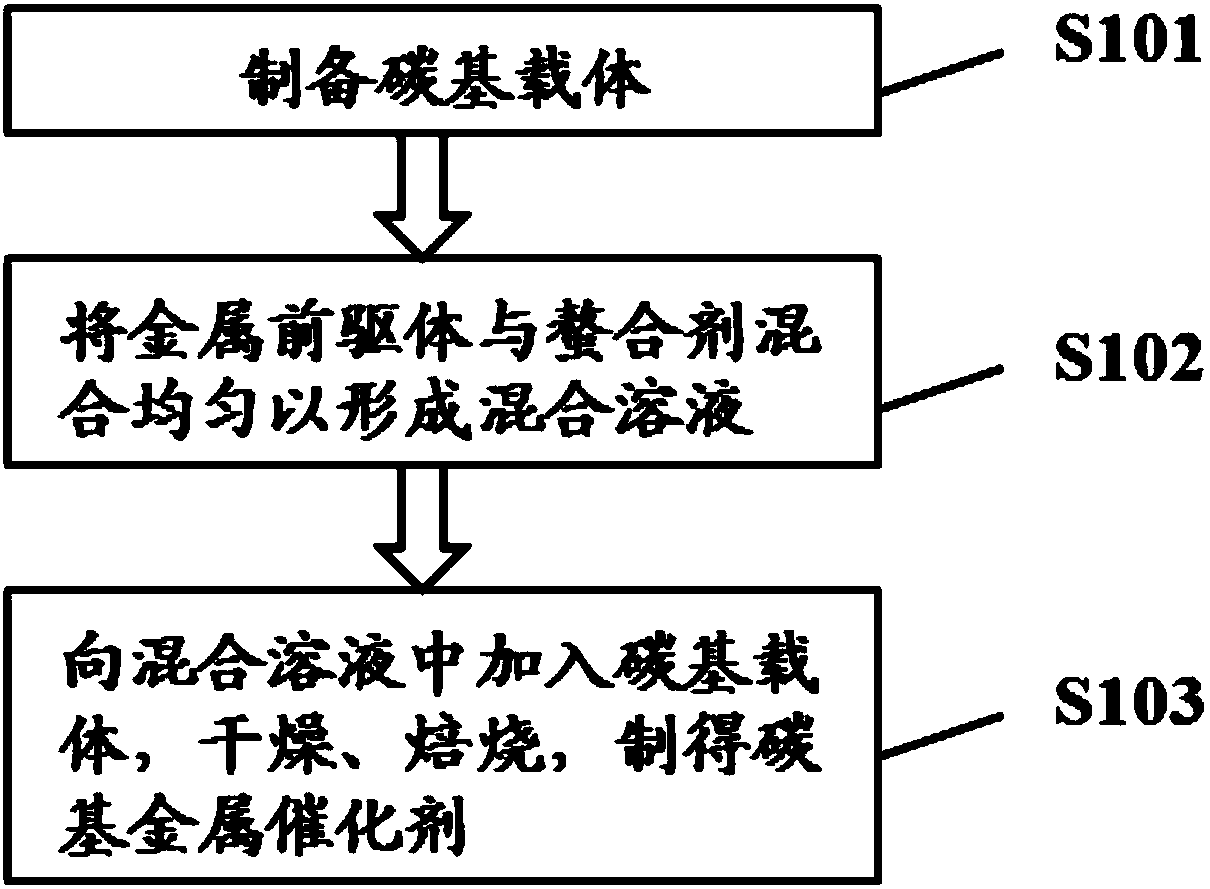

[0024] The preparation method of the carbon-based metal catalyst provided by the invention comprises the following steps:

[0025] Such as figure 1 Shown in step S101: preparing a carbon-based support. In this step, the carbon-based carrier can be prepared by freeze-drying, supercritical drying or spray-drying. Optionally, in the above-mentioned preparation method, the carbon source used is graphene oxide and butyl titanate, iso A mixed solution of one or both of aluminum propoxide and ethyl tetrasilicate, or graphene oxide. Optionally, in the above-mentioned preparation method, the solvent used is water, ethanol, isopropanol, tertiary One or more combinations of butanols. In the above preparation method, the specific surface area of the prepared carbon-based support is 1500-3000m 2 / g, porosity 70-90%, preferably, the specific surface area of the prepared carbon-based carrier is 2100-3000m 2 / g, porosity 85-90%. In this step, the preparation of carbon-based materials...

Embodiment 1

[0030] The carbon-based carrier is prepared by freeze-drying method, wherein graphene oxide is used as the carbon source, water is the solvent, and the specific surface area of the prepared carbon-based carrier graphene is 2300m 2 / g, the porosity is 80%. Platinum nitrate (Pt(NO 3 ) 2 ) as the metal precursor and the chelating agent polyvinylpyrrolidone are uniformly mixed to form a mixed solution. Add the prepared graphene to the mixed solution, and dry it at a temperature of 85°C with a rotary evaporator. During the drying process, Pt(NO 3 ) 2 , polyvinylpyrrolidone and graphene carrier are fully combined, and then roasted at a temperature of 500 ° C. After high-temperature roasting, polyvinylpyrrolidone is decomposed, and high dispersion and high loading of Pt can be obtained on the surface of graphene carrier to form Pt / graphene ene catalyst.

[0031] In the Pt / graphene catalyst prepared above, the dispersion degree of metal Pt on the surface of carbon-based support...

Embodiment 2

[0033] The carbon-based support was prepared by spray drying method, wherein graphene oxide and butyl titanate were used as carbon sources, and ethanol was used as solvent. The prepared carbon-based support graphene / TiO 2 The specific surface area is 1800m 2 / g, the porosity is 84%. Platinum nitrate (Pt(NO 3 ) 2 ) as a metal precursor and the chelating agent ethylenediaminetetraacetic acid are uniformly mixed to form a mixed solution. Adding the prepared graphene / TiO to the mixed solution 2 , using a rotary evaporator to dry it at a temperature of 90°C, during the drying process (Pt(NO 3 ) 2 ), EDTA and graphene / TiO 2 The carrier is fully combined, and then roasted at a temperature of 200 ° C, and decomposed by high-temperature roasting ethylenediaminetetraacetic acid, the graphene / TiO 2 High dispersion and high loading of Pt on the support surface to form graphene / TiO 2 catalyst.

[0034] The above-prepared Pt / graphene / TiO 2 In the catalyst, metal Pt on carbon-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com