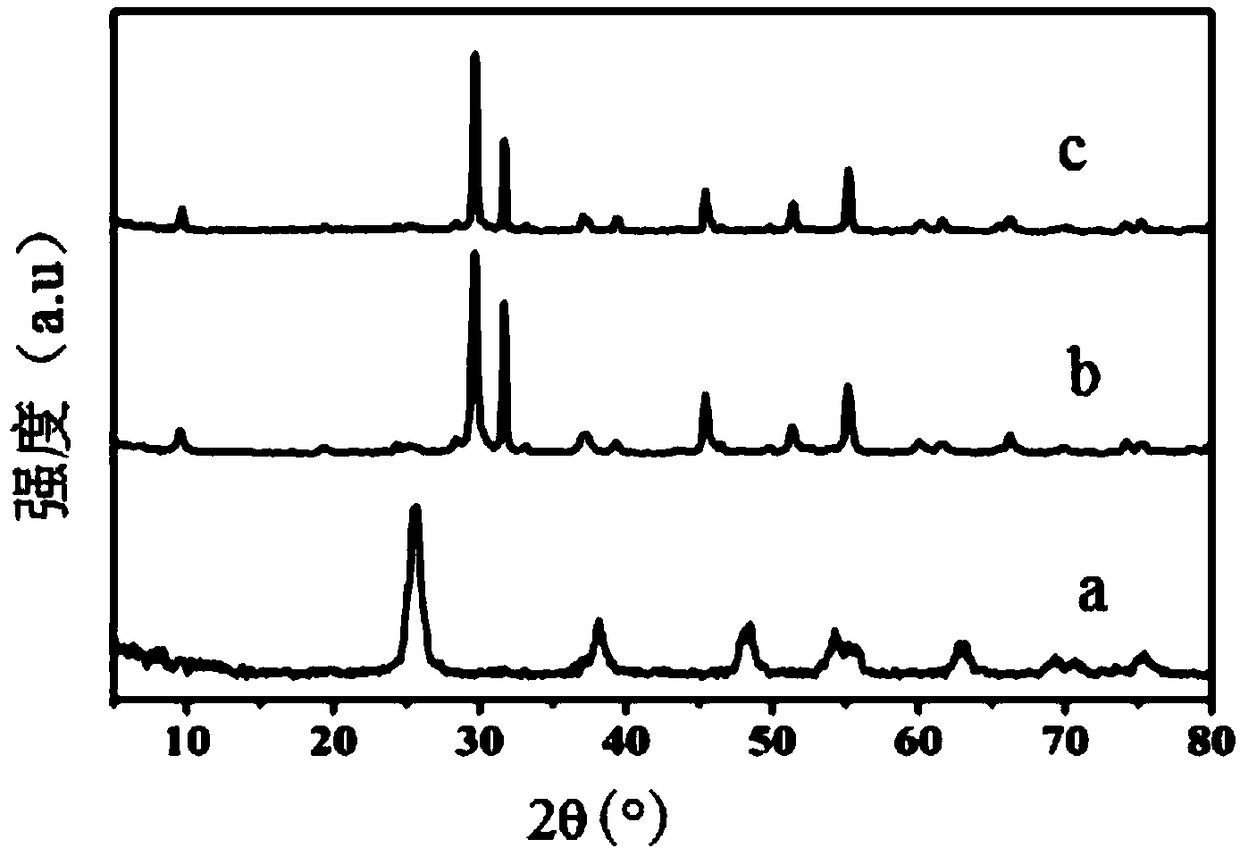

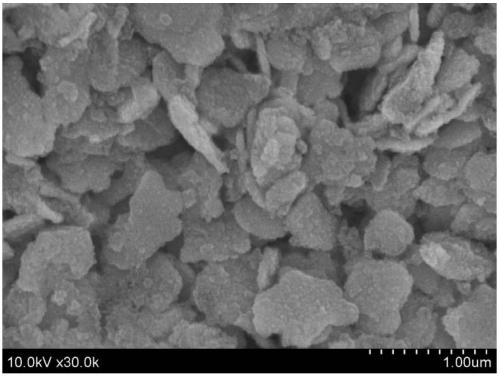

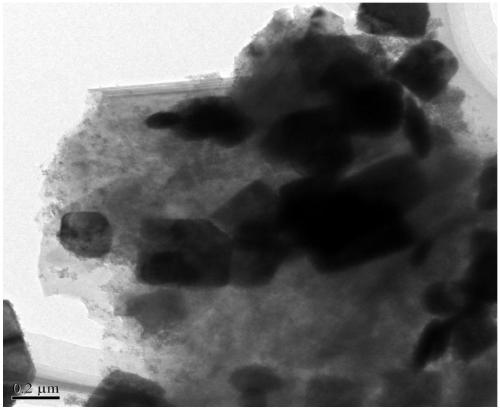

Graphene/titanium dioxide/bismuth oxyiodide ternary complex as well as preparation method and application thereof

A ternary compound and titanium dioxide technology, applied in chemical instruments and methods, water treatment of special compounds, catalyst activation/preparation, etc., can solve the problems of catalytic performance to be further improved, poor reusability, etc., to achieve enhanced reusability , reduce recombination rate and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of graphene / titanium dioxide / bismuth oxyiodide ternary compound:

[0045] Step 1, measure 5mL of tetrabutyl titanate and dissolve it in a mixed solution of 2ml of glacial acetic acid and 20ml of absolute ethanol to obtain tetrabutyl titanate solution;

[0046]Step 2: Weigh 2 mg of graphene oxide and dissolve it in 20 ml of 85% ethanol aqueous solution, sonicate for 10 min, and add 0.2 ml of concentrated nitric acid dropwise therein to obtain a graphene oxide dispersion;

[0047] Step 3. Add the tetrabutyl titanate solution dropwise to the graphene oxide dispersion at 0°C. After the dropwise addition, stir for 3 hours, and transfer the stirred suspension to a 100ml polytetrafluoroethylene-containing In a vinyl fluoride-lined high-pressure hydrothermal reactor, keep at 180°C for 7.5 hours. After the reaction is completed, cool to room temperature to obtain a graphene / titanium dioxide binary composite;

[0048] Step 4, the reaction solution is...

Embodiment 2

[0050] Step 1. Measure 5mL of tetrabutyl titanate and dissolve it in a mixed solution of 1.2ml of glacial acetic acid and 17.5ml of absolute ethanol to obtain tetrabutyl titanate solution;

[0051] Step 2: Weighing 1.5 mg of graphene oxide and dissolving it in 18 ml of 60% ethanol aqueous solution, sonicating for 10 min, and adding 0.1 ml of concentrated nitric acid dropwise thereto to obtain a graphene oxide dispersion;

[0052] Step 3. Add the tetrabutyl titanate solution dropwise to the graphene oxide dispersion at 2°C. After the dropwise addition, stir for 3 hours, and transfer the stirred suspension to a 100ml polytetrafluoroethylene-containing In a vinyl fluoride-lined high-pressure hydrothermal reactor, keep at 175°C for 8 hours, and after the reaction is completed, cool to room temperature to obtain a graphene / titanium dioxide binary composite;

[0053] Step 4: Add the reaction solution to the mixed solution of 4.1mL potassium iodide and sodium acetate (the concentrati...

Embodiment 3

[0055] Step 1. Dissolve 5 mL of tetrabutyl titanate in a mixed solution of 2.8 mL of glacial acetic acid and 22.5 mL of absolute ethanol to obtain a tetrabutyl titanate solution;

[0056] Step 2: Weigh 3 mg of graphene oxide and dissolve it in 20 ml of 70% ethanol aqueous solution, sonicate for 10 min, and add 0.3 ml of concentrated nitric acid dropwise therein to obtain a graphene oxide dispersion;

[0057] Step 3. Add the tetrabutyl titanate solution dropwise to the graphene oxide dispersion at 5°C. After the dropwise addition, stir for 3 hours, and transfer the stirred suspension to a 100ml polytetrafluoroethylene-containing In a vinyl fluoride-lined high-pressure hydrothermal reactor, keep at 190°C for 7 hours, and after the reaction is completed, cool to room temperature to obtain a graphene / titanium dioxide binary composite;

[0058] Step 4: Add the reaction solution to the mixed solution of 29.6mL potassium iodide and sodium acetate (the concentration of potassium iodid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com