A kind of technology that prepares calcium iodate with the brine after zinc oxide rinsing as raw material

A technology of zinc suboxide and calcium iodate, applied in the direction of iodine oxygen compounds, etc., can solve the problems of iodine volatilization environmental pollution, iodide instability, simple iodine volatilization, etc., to achieve convenient transportation, maintain a virtuous cycle, reduce iodine The effect of sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

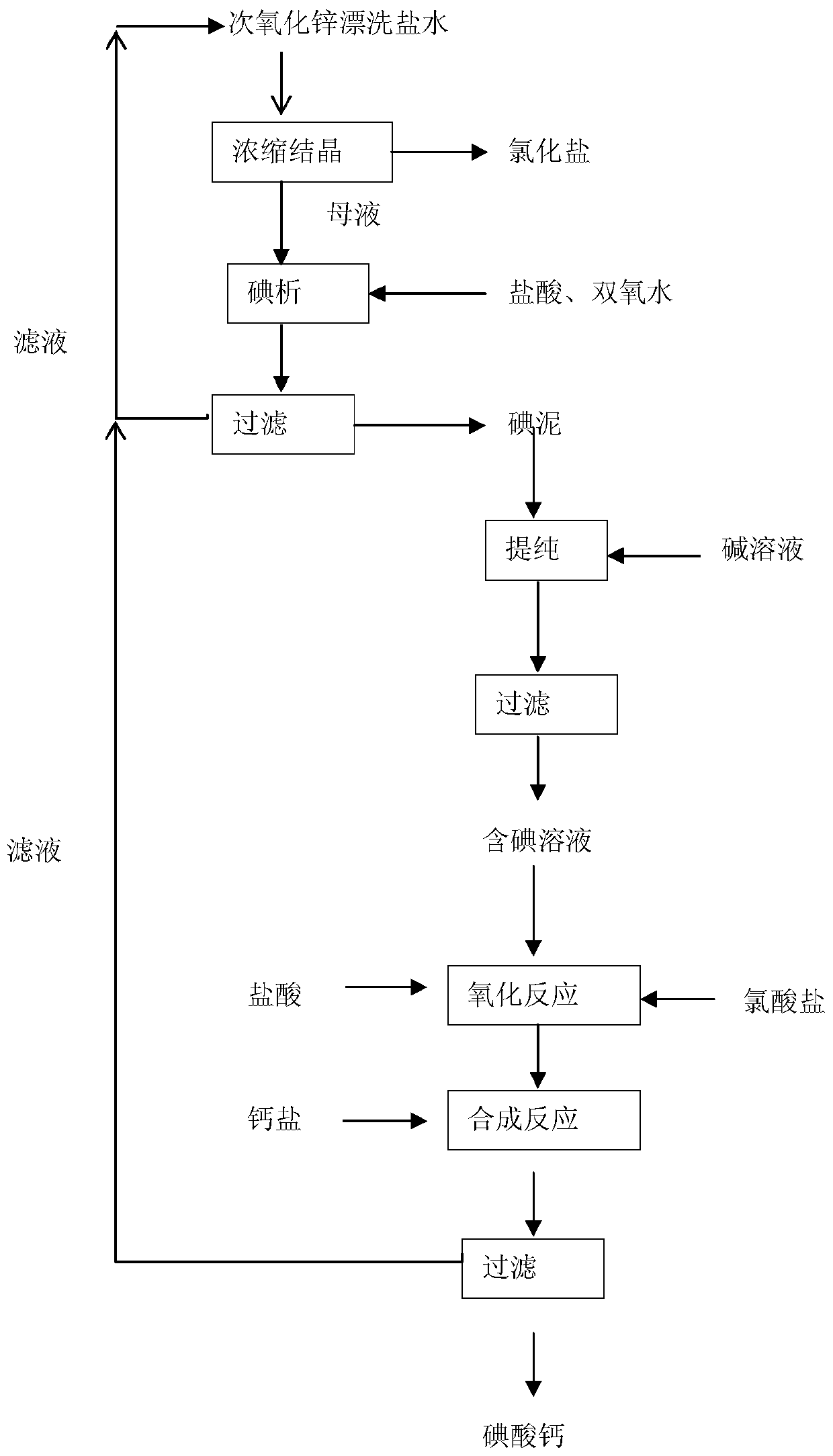

Method used

Image

Examples

Embodiment 1

[0043] A kind of technology that prepares calcium iodate with the brine after zinc oxide rinsing as raw material specifically comprises the following steps:

[0044] Step 1, rinsing: According to the ratio of zinc oxide to water mass volume 1g: 3.5ml, add water to secondary zinc oxide, after stirring for 2 hours, press filter to obtain filtrate A, said filtrate A is the secondary zinc oxide after rinsing brine;

[0045] Step 2. Evaporation and concentration: perform multi-effect evaporation and concentration on the brine obtained in step 1 after zinc oxide rinsing until the Baume degree is 50, then centrifuge, separate and recover potassium chloride and sodium chloride, and obtain the centrifuged mother liquor, i.e. iodine-containing Salt water, the existence form of iodine in the described iodine-containing salt water is sodium iodide and potassium iodide, and in the described iodine-containing salt water, I - The content is 0.8%;

[0046] Step 3, iodine analysis: add the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com