Aminated graphene oxide

A graphene and amination technology, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems affecting graphene performance, graphene curling and agglomeration, long reaction time, etc., to maintain the original characteristics, The effect of maintaining the lamellar structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

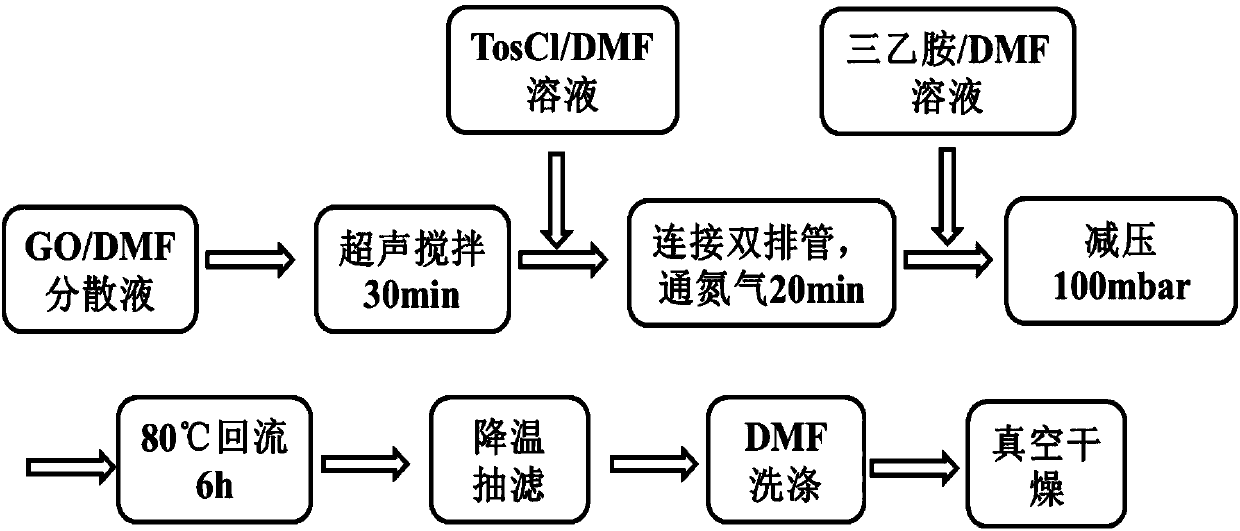

[0071] The present invention has no special limitation on the source of the graphene oxide after surface hydroxyl activation. It can be prepared from conventional sources known to those skilled in the art, and can be prepared according to conventional methods or purchased commercially. Those skilled in the art can according to actual production conditions, Modification requirements and quality control are selected and adjusted. The present invention is to further improve the properties of the product, ensure the integrity of the graphene structure, optimize and complete the reaction route, and the graphene oxide after the surface hydroxyl activation is preferably prepared by the following steps :

[0072] 1) After graphene oxide is dispersed in a polar solvent, a graphene oxide solution is obtained;

[0073] 2) After mixing the graphene oxide solution, activator and acid-binding agent obtained in the above steps, a reaction system is obtained;

[0074] 3) Under an oxygen-free...

Embodiment 1

[0160] Graphene oxide after surface hydroxyl activation

[0161] ①Add 0.75g graphene oxide slurry (mass fraction 28%) in a single-necked flask, add 100mL DMF, and ultrasonically stir for 30min to obtain a graphene oxide dispersion;

[0162] ②Add 9g of activated 5A molecular sieve to the graphene oxide dispersion in step ①, soak the dispersion for 24 hours and filter the dispersion into a three-necked flask;

[0163] ③Weigh 1.14g p-toluenesulfonyl chloride (the molar ratio of p-toluenesulfonyl chloride and graphene oxide is 3:1), add 10mL DMF to dissolve;

[0164] ④Under stirring condition, the solution obtained in step ③ is slowly added dropwise to the graphene oxide dispersion obtained in step ②;

[0165] ⑤Transfer the three-neck flask containing the dispersion liquid in step ④ to the oil bath, connect the condenser pipe and double-row pipe, and pass nitrogen for 20 minutes;

[0166]⑥Weigh 1.212g of triethylamine (the molar ratio of triethylamine to graphene oxide is 6:1), ...

Embodiment 2

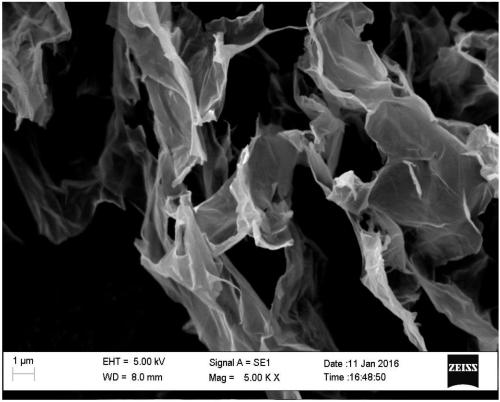

[0180] Aminated graphene oxide

[0181] ①Add 0.212g of GOTs prepared in Example 1 into a single-necked flask, add 100mL of DMF, and stir ultrasonically for 30min to obtain a GOTs / DMF dispersion;

[0182] ② Weigh 1.3g of triethylenetetramine (the mass fraction of triethylenetetramine is 68%, and the molar ratio of triethylenetetramine to GOTs is 3:1) into a three-necked flask, and add 50mL of DMF to dissolve;

[0183] ③ Slowly add the GOTs / DMF dispersion obtained in step ① to the solution obtained in step ② under the condition of stirring in an ice bath (0°C);

[0184] ④ Add the reaction solution obtained in step ③ into a microwave reactor, and react for 10 minutes at a power of 800W;

[0185] ⑤ After the reaction is completed, the product is suction-filtered, washed with absolute ethanol, and vacuum-dried at 60° C. for 12 hours to obtain aminated graphene oxide.

[0186] see image 3 , image 3 It is a schematic diagram of the process flow for preparing aminated graphene o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com