Crosslinked sulfonate carboxylate aqueous polyurethane emulsion and preparation method thereof

A technology of water-based polyurethane and sulfonic acid carboxylate, which is applied in the field of synthesis of water-based resins, and can solve problems affecting the cohesive energy and water resistance of water-based polyurethane films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

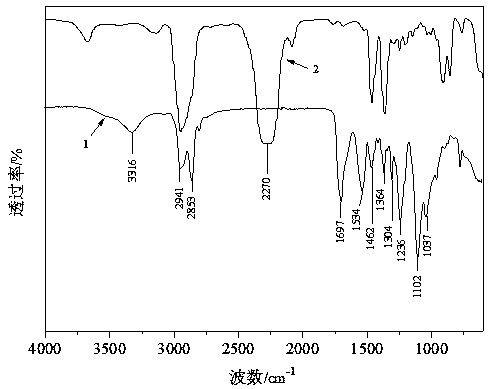

Image

Examples

Embodiment 1

[0071] a. Main reaction raw materials and proportion composition:

[0072] raw material

mass (g)

millimole (mmol)

Isophorone diisocyanate

6.68

30

N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid monosodium salt

0.60

2.38

1

7.4

1,4-Butanediol

1.02

11.3

0.75

7.4

0.12

0.2

water

20

1111

Polytetrahydrofuran ether glycol

6.14

6.1

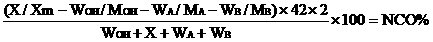

[0073] The reaction raw material diisocyanate is isophorone diisocyanate, the trifunctional sulfonate is N-tris(hydroxymethyl)methyl-2-aminoethanesulfonic acid monosodium salt, and the hydrophilic chain extender is dimethylol Propionic acid, small molecule chain extender is 1,4-butanediol, salt forming agent is triethylamine, organotin catalyst is dibutyltin dilaurate, deionized water, macromolecule glycol is polytetrahydrofuran ether diol Alcohols, their molar ratio...

Embodiment 2

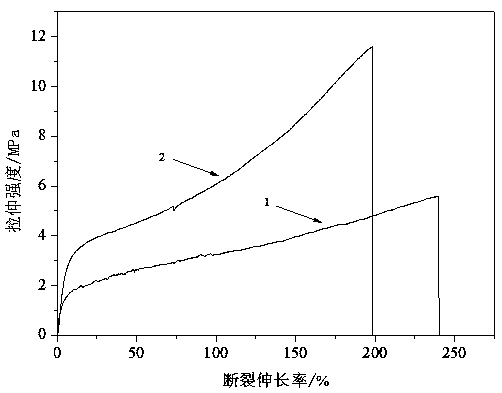

[0081] Embodiment 2 differs from Example 1 in that: polytetrahydrofuran ether glycol (PTMG Mn=1000) added in step b is changed to molecular weight and is the polycaprolactone glycol of 1000g / mol, and other processes do not Change, obtain a kind of stable blue translucent cross-linked sulfonic acid carboxylate water-based polyurethane emulsion, wherein the water-based polyurethane macromolecular segment nano-spherical colloid particle diameter is 42nm, molecular weight is 12800, and mass percent is solid content is 44%, the water absorption rate of the water-based polyurethane film after drying into a film is 19.4%, the tensile strength is 10.6MPa, and the elongation at break is 220%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com