Preparation method of crystalline-amorphous aluminum-based composite material

An aluminum-based composite material and amorphous technology, which is applied in the field of casting aluminum alloy preparation, can solve problems such as poor plasticity at room temperature, and achieve the effects of less severe segregation, fast metal solidification, and extremely high metal solidification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a crystal-amorphous aluminum-based composite material, comprising the following steps:

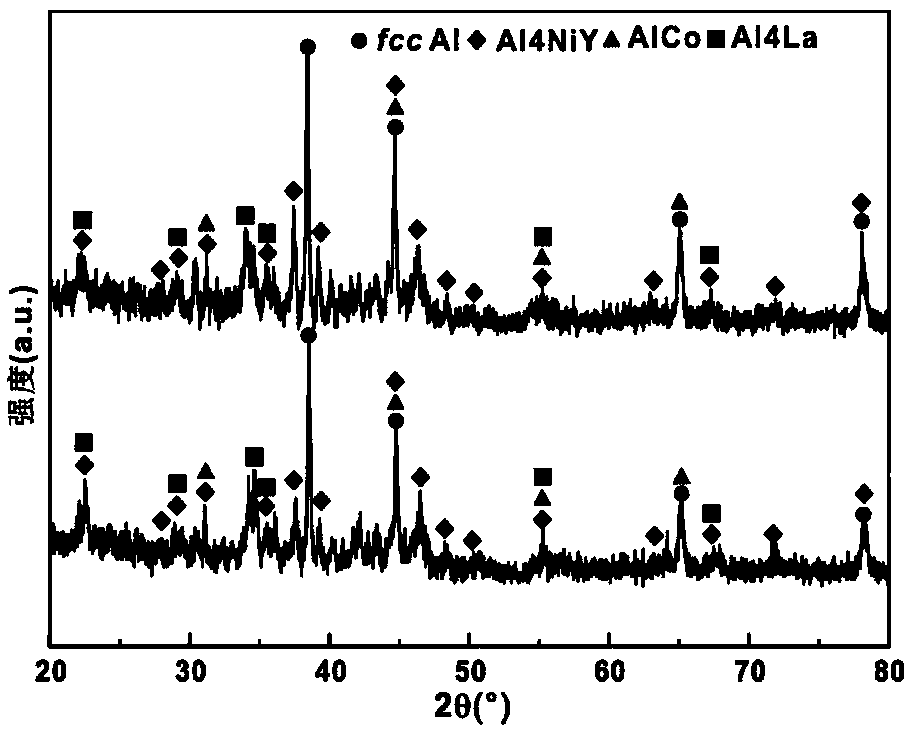

[0031] (1) Weigh Al, Ni, Co, Y and La high-purity metal elemental substances respectively according to the molar ratio of 86:6.75:2.25:3.25:1.75, the mass fraction of each metal elemental substance is ≥99.99wt.%, mixing, smelting; multiple times Alloy master ingot Al was prepared after smelting 86 Ni 6.75 co 2.25 Y 3.25 La 1.75 ;

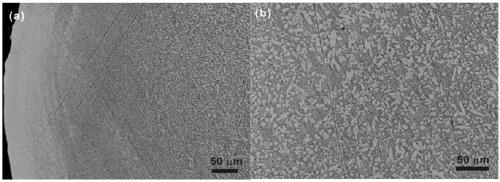

[0032] (2) After the alloy master ingot is arc-melted under an argon protective atmosphere, the crystal-amorphous aluminum matrix composite material is prepared by rapid suction casting using a water-cooled copper mold as the cooling medium; the cooling speed of the suction casting process combined with the copper mold mold for 10 3 K / s~10 6 K / s, and the cooling rate of the upper part of the copper mold is lower than that of the lower part.

[0033] The invention utilizes the pressure difference between the furnace body and ...

Embodiment 1

[0046] A method for preparing a crystal-amorphous aluminum-based composite material, comprising the following steps:

[0047] (1) Finely grind Al, Ni, Co, Y and La metal elements to remove scale and attached impurities, respectively weigh Al, Ni, Co, Y and La according to the molar ratio of 86:6.75:2.25:3.25:1.75 Simple substance (weighing error is controlled within ±0.001g), after mixing, prepare 30g metal simple substance mixture, place the metal simple substance mixture in ethanol-acetone mixed solution and ultrasonically clean it for 10min to remove attached impurities, put it into high vacuum arc after drying In the smelting furnace, the alloy master ingot Al was prepared after repeated smelting 5 times 86 Ni 6.75 co 2.25 Y 3.25 La 1.75 , in the vacuum arc melting process, the absolute vacuum degree is 8.0×10 -4 ~2.5×10 -3 Within the range of Pa, then backfill argon with a purity of 99.999% to 0.5±0.05 atmospheres;

[0048] (2) Cut the prepared alloy master ingot i...

PUM

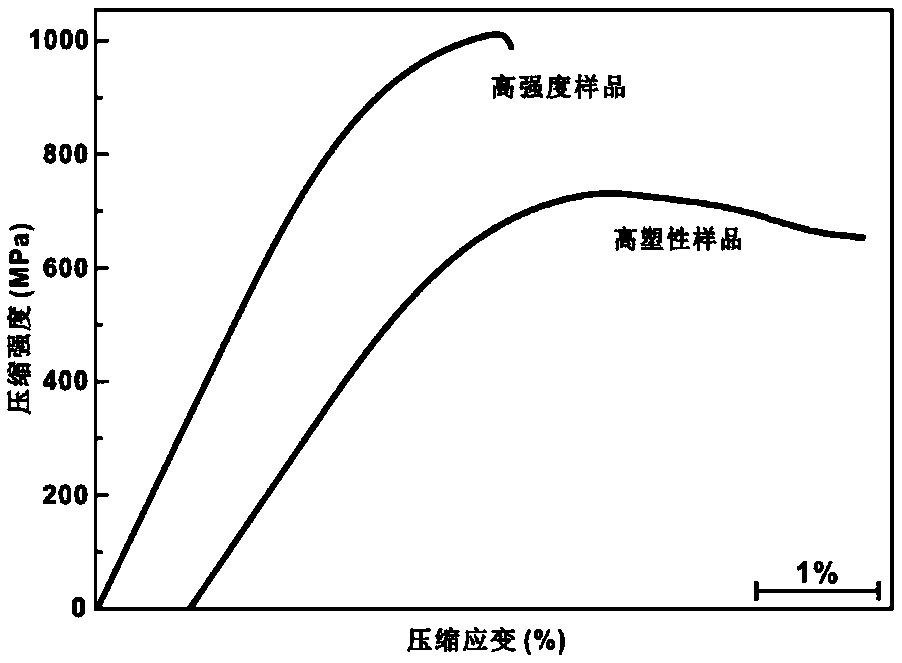

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com