Supported nickel-based catalyst, preparation method and applications thereof

A nickel-based catalyst, supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high cost of precious metal catalysts and achieve good application prospects , The effect of accelerating the hydrogenation reaction speed and high anti-sulfur poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

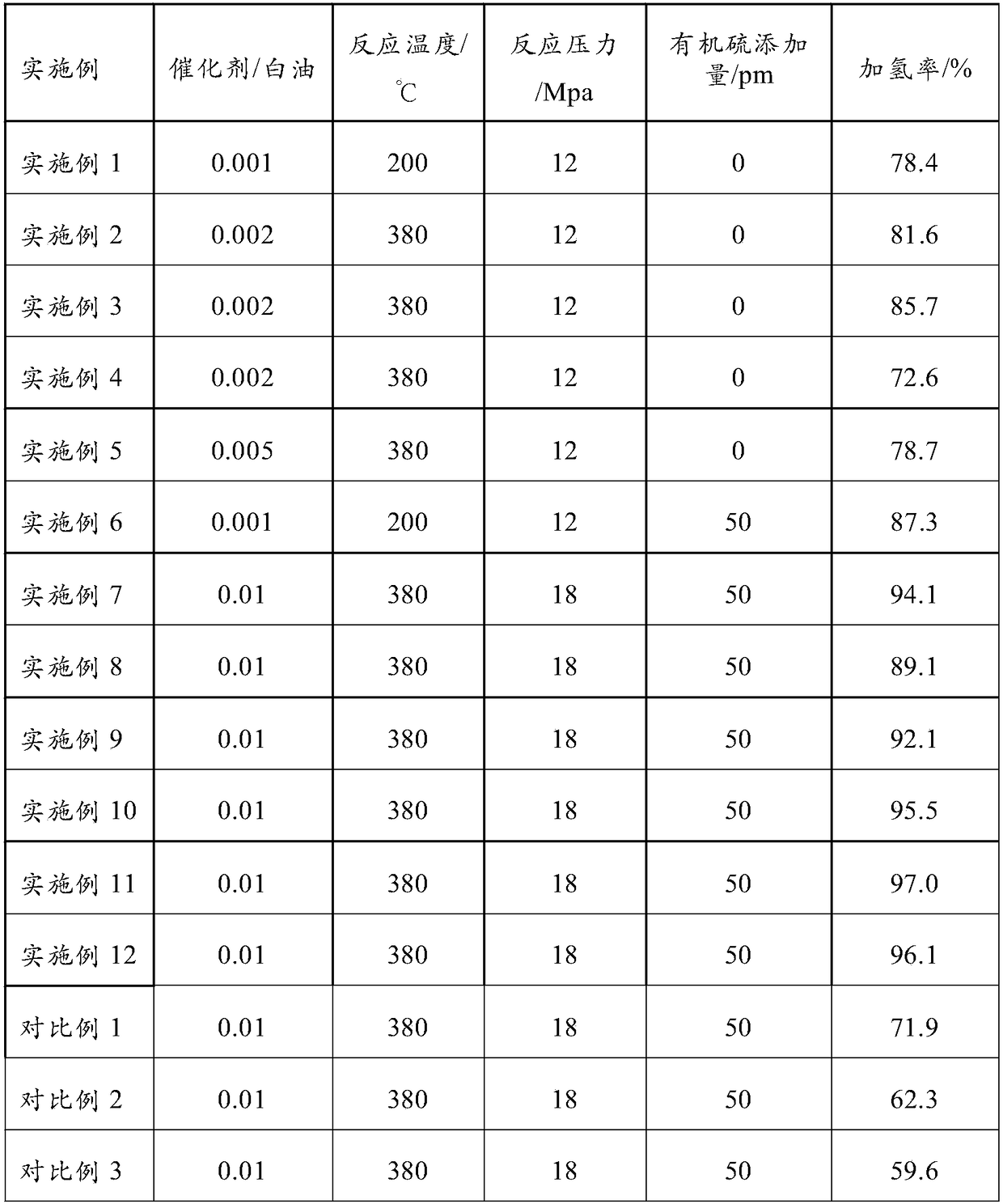

Examples

preparation example Construction

[0049] On the other hand, the embodiment of the present invention also provides a preparation method of the supported nickel-based catalyst, comprising the following steps:

[0050] Step S1, providing a nickel-containing precursor, a zinc-containing precursor, a magnesium-containing precursor, a composite carrier, an alkaline soluble matter and deionized water, and the nickel-containing precursor, the zinc-containing precursor and the The magnesium precursor is mixed and dissolved in the deionized water to form a precursor solution, and the alkaline soluble matter is dissolved in the deionized water to form an alkaline aqueous solution;

[0051] Step S2, mixing the precursor solution, the alkaline aqueous solution and the composite carrier and performing a co-precipitation reaction to form a slurry;

[0052] Step S3, filtering the slurry to obtain a filter cake, and then sequentially washing, drying and pulverizing the filter cake to obtain a first catalyst powder;

[0053] S...

Embodiment 1

[0060] This embodiment provides a supported nickel-based catalyst, the composition of the supported nickel-based catalyst is 60Ni-1Zn-1Mg / 30SiO 2 -8TiO 2 , the supported nickel-based catalyst described in this embodiment is prepared by the following method, the method comprising: accurately weighing 113.6g of Na 2 CO 3 Place in a 5L three-necked flask, add 1.2L deionized water and heat to dissolve, accurately weigh 30.0g of silicon dioxide and 8.0g of titanium dioxide and add them to the three-necked flask for heating and stirring to obtain silicon , titanium dioxide and Na 2 CO 3 For the mixed slurry composed of the solution, when the temperature rises to 50°C, the pre-prepared aqueous solution containing active components nickel, zinc and magnesium is added dropwise to the above mixed slurry within 0.5h to carry out the precipitation reaction.

[0061] After the mother liquor was removed by filtration, it was washed with deionized water at about 60° C. until the pH of...

Embodiment 2

[0066] This embodiment provides a supported nickel-based catalyst, the composition of the supported nickel-based catalyst is 60Ni-1Zn-1Mg / 30SiO 2 -8TiO 2 , the supported nickel-based catalyst described in this embodiment is prepared by the following method, the method comprising: accurately weighing 113.6g of Na 2 CO 3 Place in a 5L three-necked flask, add 1.2L deionized water and heat to dissolve, accurately weigh 30.0g of silicon dioxide and 8.0g of titanium dioxide and add them to the three-necked flask for heating and stirring to obtain silicon , titanium dioxide and Na 2 CO 3 For the mixed slurry composed of the solution, when the temperature rises to 50°C, the pre-prepared aqueous solution containing active components nickel, zinc and magnesium is added dropwise to the above mixed slurry within 2.0 hours to carry out precipitation reaction.

[0067] After the mother liquor was removed by filtration, it was washed with deionized water at room temperature until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com