Preparation method of soil conditioner

The technology of soil conditioner and bacterial agent is applied in the field of soil improvement, which can solve the problems of short duration of action, complicated production process and high cost of raw materials, and achieve the effect of promoting production, reducing soil bulk density and achieving good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

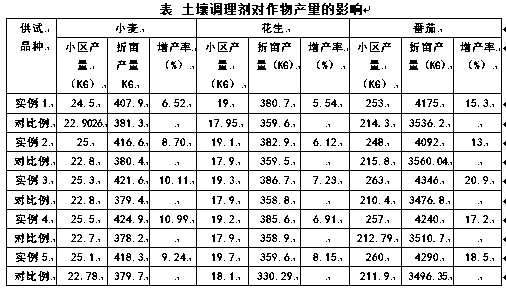

Examples

Embodiment 1

[0020] The proportions of the fermented product of the soil conditioner of this embodiment and the microbial composite bacterial agent are as follows in parts by weight: 65 parts of fresh pig manure (water content 80%), 25 parts of straw powder (water content 15%), and 5 parts of superphosphate , 2 parts of urea, 2.5 parts of potassium chloride, and 0.5 part of microbial compound bacteria agent.

[0021] The specific production method is as follows:

[0022] Crush the collected straw into particles with a diameter of 2-3cm, add livestock and poultry manure according to the above ratio, stir evenly, then add microbial compound bacteria agent, superphosphate, urea, and potassium chloride according to the ratio, and stir evenly again, The mixture is piled into strips, the height of which does not exceed 1.1 meters, and the fermentation is carried out under the condition that the temperature of the fermentation environment is higher than 20 degrees. If the fermentation temperatur...

Embodiment 2

[0024] The ratio of the fermented product of the soil conditioner of this embodiment and the microbial composite bacterial agent is as follows by weight: 50 parts of fresh cow dung (water content 80%), 20 parts of chicken manure dry (water content 15%), straw powder (containing 20 parts of water (15%), 4 parts of superphosphate, 3 parts of urea, 2.5 parts of potassium chloride, and 0.5 parts of microbial compound bacteria agent.

[0025] The specific production method is as follows:

[0026] Crush the collected straw into particles with a diameter of 2-3cm, add livestock and poultry manure according to the above ratio, stir evenly, then add microbial compound bacteria agent, superphosphate, urea, and potassium chloride according to the ratio, and stir evenly again, The mixture is piled into strips, the height of which does not exceed 1.1 meters, and the fermentation is carried out under the condition that the temperature of the fermentation environment is higher than 20 degree...

Embodiment 3

[0028] The fermented product of the soil conditioner of the present embodiment and the microbial composite bacterial agent proportioning are as follows in parts by weight:

[0029] 65 parts of fresh chicken manure (water content 70%), 27 parts of straw powder (water content 15%), 4 parts of superphosphate, 2 parts of urea, 1.5 parts of potassium chloride, 0.5 parts of microbial compound bacteria agent.

[0030] The specific production method is as follows:

[0031] Crush the collected straw into particles with a diameter of 2-3cm, add livestock and poultry manure according to the above ratio, stir evenly, then add microbial compound bacteria agent, superphosphate, urea, and potassium chloride according to the ratio, and stir evenly again, The mixture is piled into strips, the height of which does not exceed 1.1 meters, and the fermentation is carried out under the condition that the temperature of the fermentation environment is higher than 20 degrees. If the fermentation tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com