A kind of copper-plated grid graphene and preparation method thereof

A graphene and graphene nanosheet technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem that the dispersion of the coating is not dense and uniform, it is difficult to uniformly disperse and mix, and it is difficult to uniformly disperse and mix, etc. The problem is to achieve the effect of convenient preparation method, no porosity, mechanical bonding strength, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Prepare grid-like graphene nanosheets,

[0040] Take non-sensitization and non-activation treatment to graphene surface: first adopt NaOH solution (mass fraction is 10%) boiling alkali washing 20min to the graphene nanosheet of original material, the solution after alkali washing is cooled to room temperature and filtered, and pass Rinse with distilled water until neutral; then use HNO for graphene nanosheets 3 The solution (mass fraction is 1%) was boiled and pickled for 1min, the solution after the pickling was cooled to room temperature and filtered, and rinsed with distilled water to neutrality, and the graphene surface impurities and roughening treatment were removed by alkali washing and pickling.

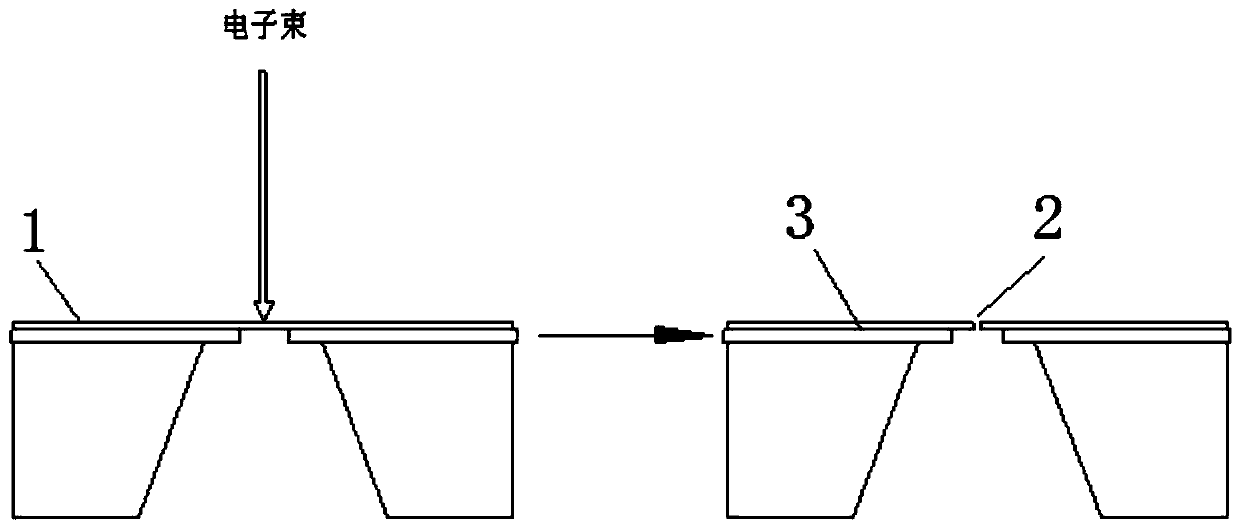

[0041] Put the transferred graphene nanosheets into the transmission electron microscope rod and move into the vacuum punching chamber. After reaching high vacuum, under 200KV voltage, adjust the current density to 1×10 5 A / m 2 , finish punching holes on gra...

Embodiment 2

[0049] Step 1: Prepare grid-like graphene nanosheets,

[0050] Take non-sensitization and non-activation treatment to graphene surface: first adopt NaOH solution (mass fraction is 15%) boiling alkali washing 23min to the graphene nanosheet of original material, the solution after alkali washing is cooled to room temperature and filtered, and pass Rinse with distilled water until neutral; then use HNO for graphene nanosheets 3 The solution (mass fraction is 3%) is boiled and pickled for 1.5min, the solution after the pickling is cooled to room temperature and filtered, and rinsed with distilled water to neutrality, and the surface impurities and roughening treatment of graphene are removed by alkali washing and pickling .

[0051] Put the transferred graphene nanosheets into the transmission electron microscope rod and move into the vacuum punching chamber. After reaching a high vacuum, under the voltage of 230KV, adjust the current density to 2×10 5 A / m 2 , finish punching...

Embodiment 3

[0059] Step 1: Prepare grid-like graphene nanosheets,

[0060] Take non-sensitization and non-activation treatment to graphene surface: first adopt NaOH solution (mass fraction is 20%) boiling alkali washing 25min to the graphene nanosheet of raw material, the solution after alkali washing is cooled to room temperature and filtered, and pass Rinse with distilled water until neutral; then use HNO for graphene nanosheets 3 The solution (mass fraction is 5%) was boiled and pickled for 2min, and the solution after the pickling was cooled to room temperature with cold water and filtered, and washed to neutrality by distilled water, and the surface impurities and roughening treatment of graphene were removed by alkali washing and pickling.

[0061] Put the transferred graphene nanosheets into the transmission electron microscope rod and move into the vacuum punching chamber. After reaching high vacuum, under 250KV voltage, adjust the current density to 3×10 5 A / m 2 , finish punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com