Tea polyphenol-modified graphene-loaded nano-iron material, and preparation method and application thereof

A technology of tea polyphenols and graphene, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of poor dispersibility, weak oxidation resistance, application limitations, etc., and achieve reduced aggregation. , strong adsorption capacity, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Take 1g FeSO 4 ·7H 2 O was added to 120mL of ethanol solution with a volume fraction of 30%, stirred to make it dissolve completely to form a mixed solution;

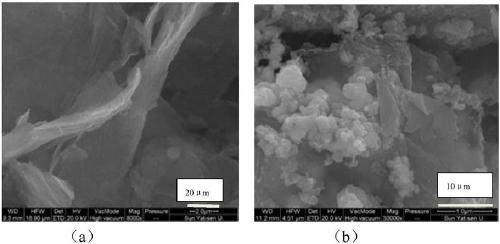

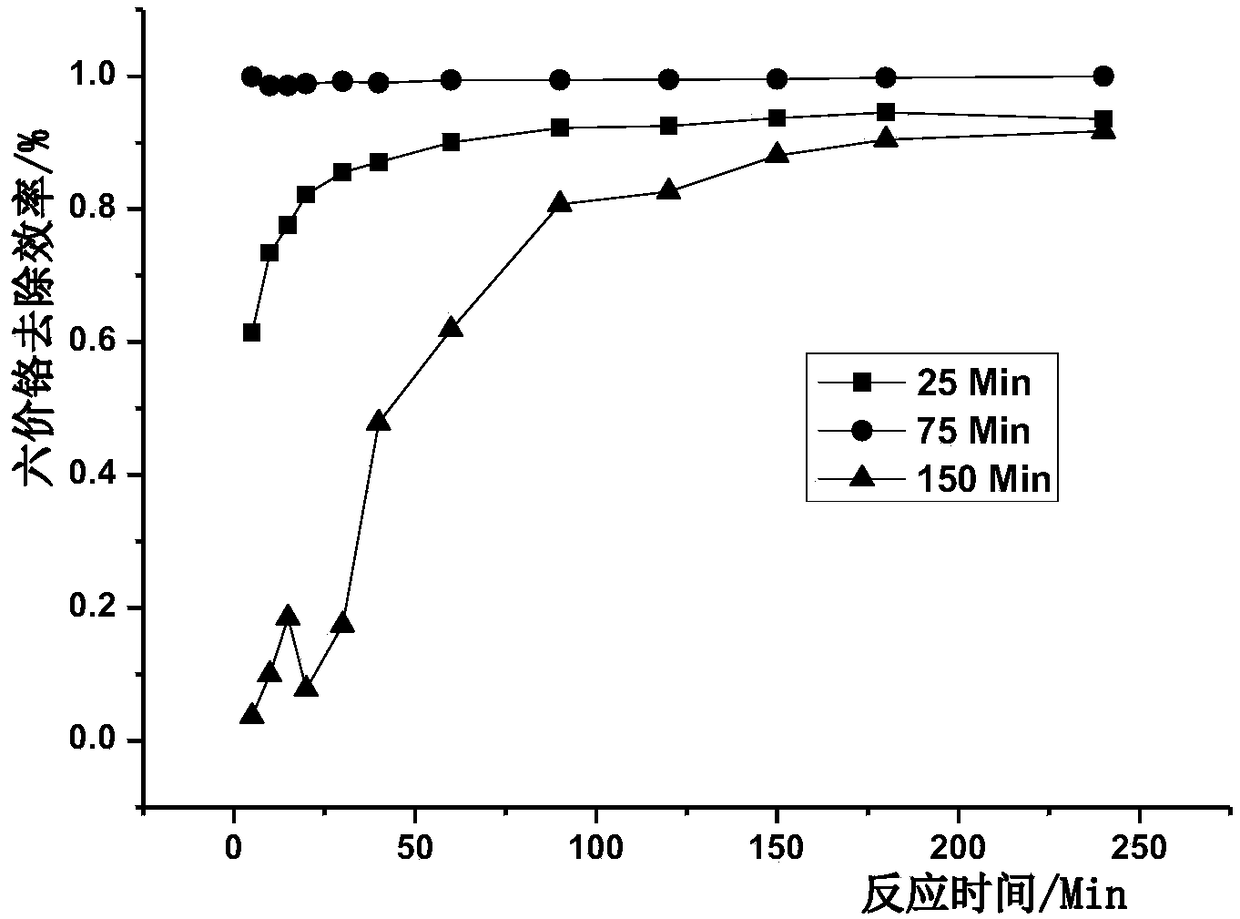

[0038] (2) Under closed conditions, feed nitrogen protection, accurately weigh graphene by mass ratio=1:4 of Fe simple substance in the reaction system: graphene and join in the mixed solution that step (1) obtains, add 0.33mL PEG-400, ultrasonically dispersed for 30min, at a stirring frequency of 500rpm, 10ml of tea polyphenol aqueous solution with a concentration of 100g / L was added dropwise and reacted for 25min, filtered and vacuum-dried at 50°C for 12h to obtain the tea polyphenol-modified graphene Loading nano-iron material.

Embodiment 2

[0040] (1) Take 1g FeSO 4 ·7H 2 O was added to 120mL of ethanol solution with a volume fraction of 30%, stirred to make it dissolve completely to form a mixed solution;

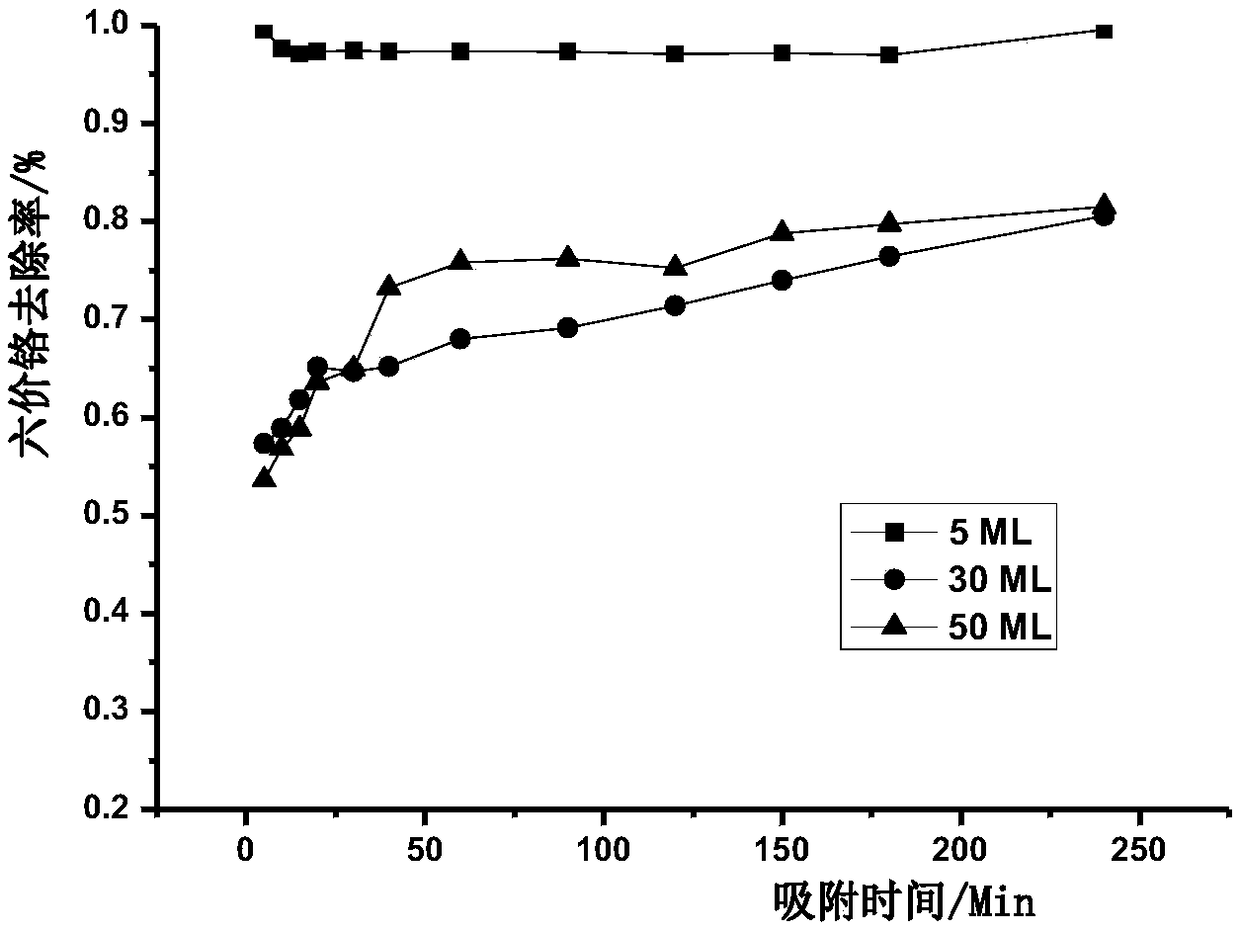

[0041] (2) Under closed conditions, feed nitrogen protection, accurately weigh graphene by mass ratio=1:4 of Fe simple substance in the reaction system: graphene and join in the mixed solution that step (1) obtains, add 0.33mL PEG-400, ultrasonically disperse for 30min, at a stirring frequency of 500rpm, add 10ml of tea polyphenol aqueous solution with a concentration of 100g / L dropwise and react for 75min, filter and vacuum dry at 50°C for 12h to obtain the tea polyphenol-modified graphene Loading nano-iron material.

Embodiment 3

[0043] (1) Take 1g FeSO 4 ·7H 2 O was added to 120mL of ethanol solution with a volume fraction of 30%, stirred to make it dissolve completely to form a mixed solution;

[0044] (2) Under closed conditions, feed nitrogen protection, accurately weigh graphene by mass ratio=1:4 of Fe simple substance in the reaction system: graphene and join in the mixed solution that step (1) obtains, add 0.33mL PEG-400, ultrasonically dispersed for 30min, at a stirring frequency of 500rpm, 10ml of tea polyphenol aqueous solution with a concentration of 100g / L was added dropwise and reacted for 150min, filtered and vacuum-dried at 50°C for 12h to obtain the tea polyphenol-modified graphene Loading nano-iron material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com