A preparation method of a high-rate silicon oxide-based lithium battery negative electrode material

A technology of silicon oxide-based lithium and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor electronic ion conductance, etc., and achieve the effects of accelerating kinetics, stabilizing cycle performance, and buffering volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present disclosure discloses a method for preparing a high-rate silicon oxide-based lithium battery negative electrode material. The method specifically includes the following steps:

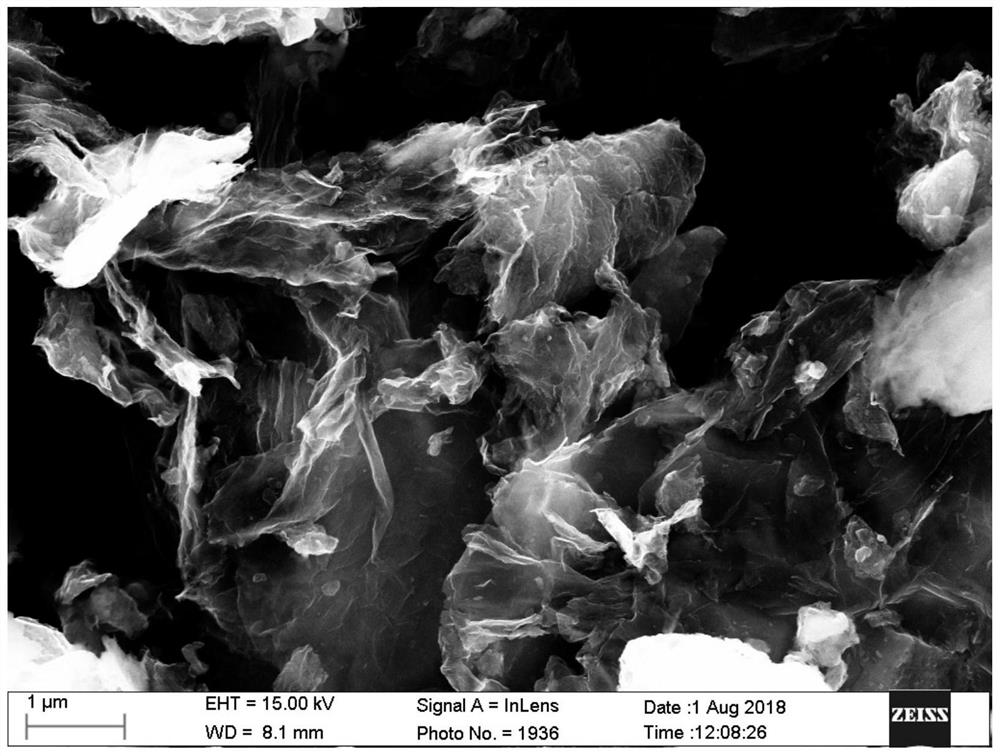

[0027] Step 1. Preparation of silicon oxide-carbon / graphene powder:

[0028] 1.1 Take a certain amount of silicon ester and dissolve it in ethanol, then add ionized water and hydrochloric acid, and stir evenly to obtain the mixed solution A;

[0029] 1.2 Take a certain amount of sucrose, put it in the graphene oxide dispersion, stir until dissolved, and obtain the mixed solution B;

[0030] 1.3 Add ammonia water to the mixed solution A to adjust the pH value, first obtain the silicone gel, and after the reaction is completed, continue to add the mixed solution B to the silicone gel to obtain a silicon-oxygen-sucrose-graphene oxide brown gel;

[0031] 1.4 Mill the silicon-oxygen-sucrose-graphene oxide brown gel in a ball mill jar for a period of time, and then transf...

Embodiment 1

[0046] Weigh 2.5 g of tetraethyl orthosilicate and dissolve it in 4 mL of ethanol, stir for a while, then add 2 mL of deionized water and 1 mL of hydrochloric acid into it to obtain a mixed solution A. After the mixture A was vigorously stirred for 1 hour, a silica sol was obtained, and the pH of the sol was adjusted to 6.5 with 1M ammonia water, and the stirring was continued for a period of time to obtain a silica gel. Measure 70 mL of graphene oxide dispersion, graphene oxide concentration is 4 mg mL -1 , then weighed 0.6 g of sucrose and added it, and stirred until completely dissolved to obtain the mixed solution B.

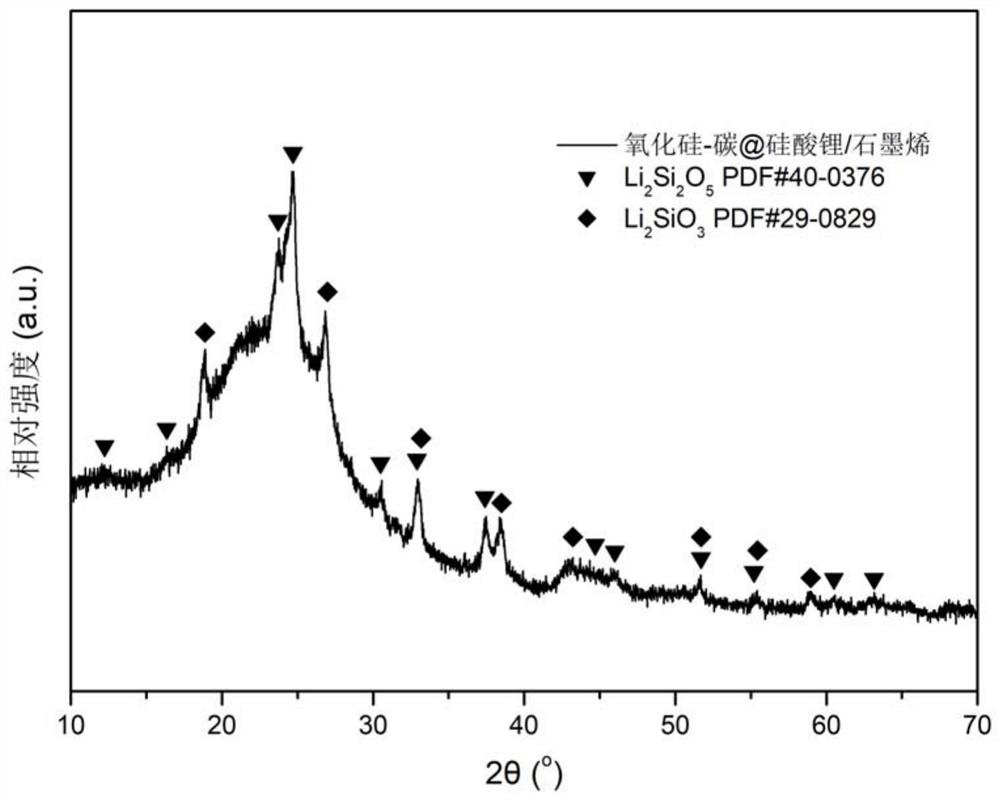

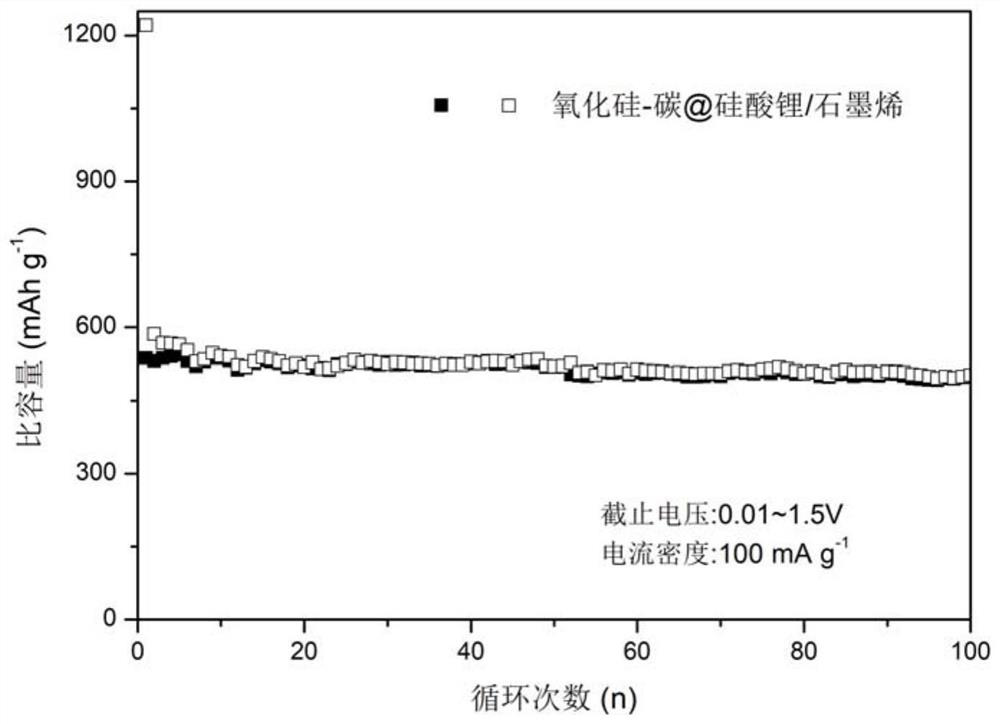

[0047] Add the mixed solution B to the silicone gel, and after stirring for a period of time, a silicon-oxygen-sucrose-graphene oxide brown gel is obtained. The brown gel was transferred to a ball mill tank, the ball milling speed was 300 rpm, and the ball milling time was 3 h. The brown gel after ball milling was transferred to a freeze dryer, and the dryi...

Embodiment 2

[0052] Weigh 3 g of ethyl orthosilicate and dissolve it in 4 mL of ethanol, stir for a while, then add 2 mL of deionized water and 1 mL of hydrochloric acid into it to obtain a mixed solution A. After the mixture A was vigorously stirred for 1 hour, a silica sol was obtained, and the pH of the sol was adjusted to 6.5 with 1M ammonia water, and the stirring was continued for a period of time to obtain a silica gel. Measure 160 mL of graphene dispersion, the content of graphene oxide is 8 mg mL -1 , then weighed 2 g of sucrose and added it, stirred until completely dissolved, and obtained the mixed solution B.

[0053] Add the mixed solution B into the silicone gel, and after stirring for a period of time, a silicon-oxygen-sucrose-graphene oxide brown gel is obtained. The brown gel was transferred to a ball mill jar, the ball milling speed was 150 rpm, and the ball milling time was 7 h. The brown gel after ball milling was transferred to a freeze dryer, and the drying time was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com