Solvent-free and kilogram-scale preparation method for regular mesoporous phenol-formaldehyde resin

A phenolic resin, kilogram technology, applied in the field of material science, can solve the problems of cumbersome preparation process, unfavorable industrial production, high synthesis cost, and achieve the effects of green preparation process, improved surface alkalinity, and good adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

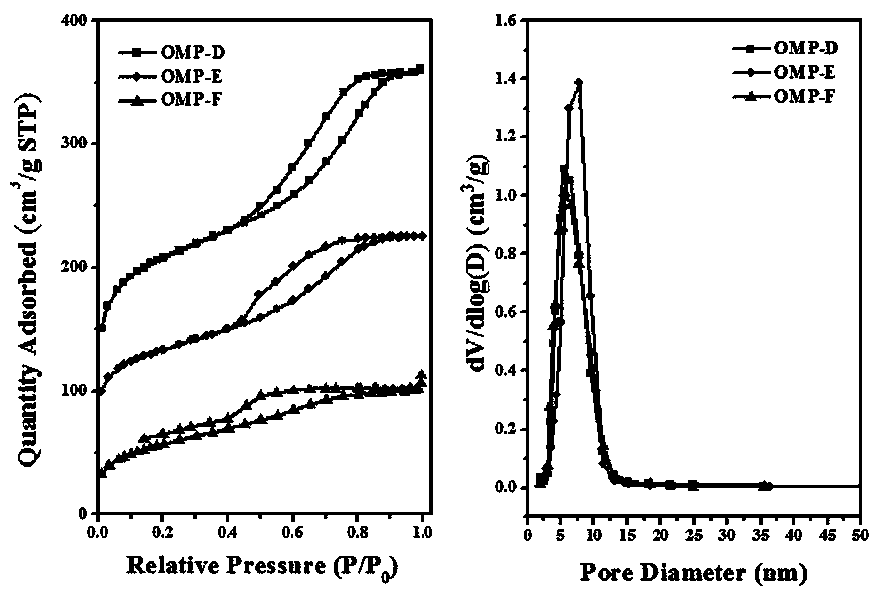

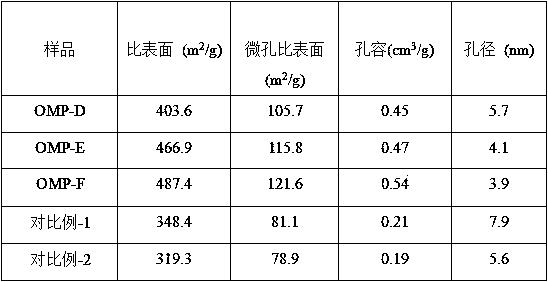

[0029] This embodiment provides a solvent-free regular mesoporous polymer with m-aminophenol as the phenolic organic compound, terephthalaldehyde as the aldehyde compound, and F127 as the block template polymer.

[0030] Its preparation method comprises the following steps:

[0031] Weigh 2.2g of block copolymer template, 0.47g of m-aminophenol and 0.64g of terephthalaldehyde in 50ml of polytetrafluoroethylene lining. Drying oven, curing at 140°C for 24 hours, the curing temperature rising rate is 5°C / min, the obtained sample is transferred to a tube furnace, and carbonized at 360°C for 5 hours under a nitrogen atmosphere, the carbonization heating rate is 5°C / min, and the removed The regular mesoporous polymer after removing the templating agent is denoted as OMP-A.

Embodiment 2

[0033] This embodiment provides a solvent-free regular mesoporous polymer with m-aminophenol as the phenolic organic compound, terephthalaldehyde as the aldehyde compound, and F127 as the block template polymer.

[0034] Its preparation method comprises the following steps:

[0035] Weigh 11g of block copolymer template, 2.35g of m-aminophenol and 3.2g of terephthalaldehyde in 50ml of polytetrafluoroethylene lining. box, cured at 140°C for 24 hours, the curing temperature rise rate was 5°C / min, the obtained sample was transferred to a tube furnace, and carbonized at 360°C for 5 hours under a nitrogen atmosphere, the carbonization temperature rise rate was 5°C / min, and the removal The regular mesoporous polymer after the template is denoted as OMP-B.

Embodiment 3

[0037] This embodiment provides a solvent-free regular mesoporous polymer with m-aminophenol as the phenolic organic compound, terephthalaldehyde as the aldehyde compound, and F127 as the block template polymer.

[0038] Its preparation method comprises the following steps:

[0039] Weigh 22g of block copolymer template, 4.3g of m-aminophenol and 6.1g of terephthalaldehyde in 100ml of polytetrafluoroethylene lining. Box, cured at 140°C for 24 hours, the curing temperature rise rate was 5°C / min, the obtained sample was transferred to a tube furnace, and carbonized at 360°C for 5 hours under a nitrogen atmosphere, the carbonization temperature rise rate was 5°C / min, and the template was removed The regular mesoporous polymer after curing is denoted as OMP-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com