Fireproof cable and preparation method thereof

A technology for fireproof cables and cables, applied in rubber insulators, organic insulators, etc., can solve problems such as unsatisfactory fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

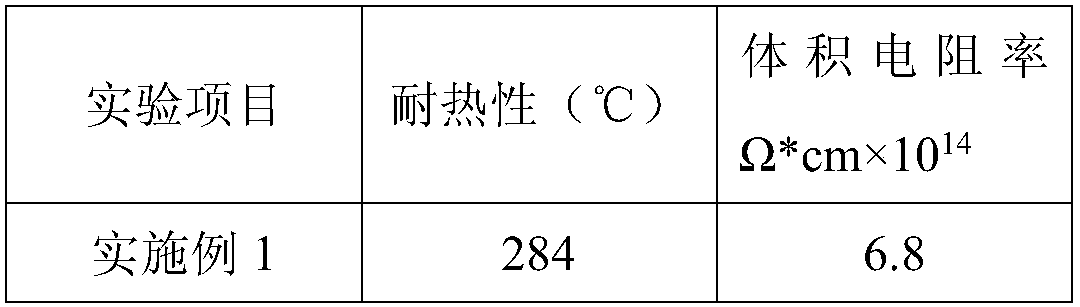

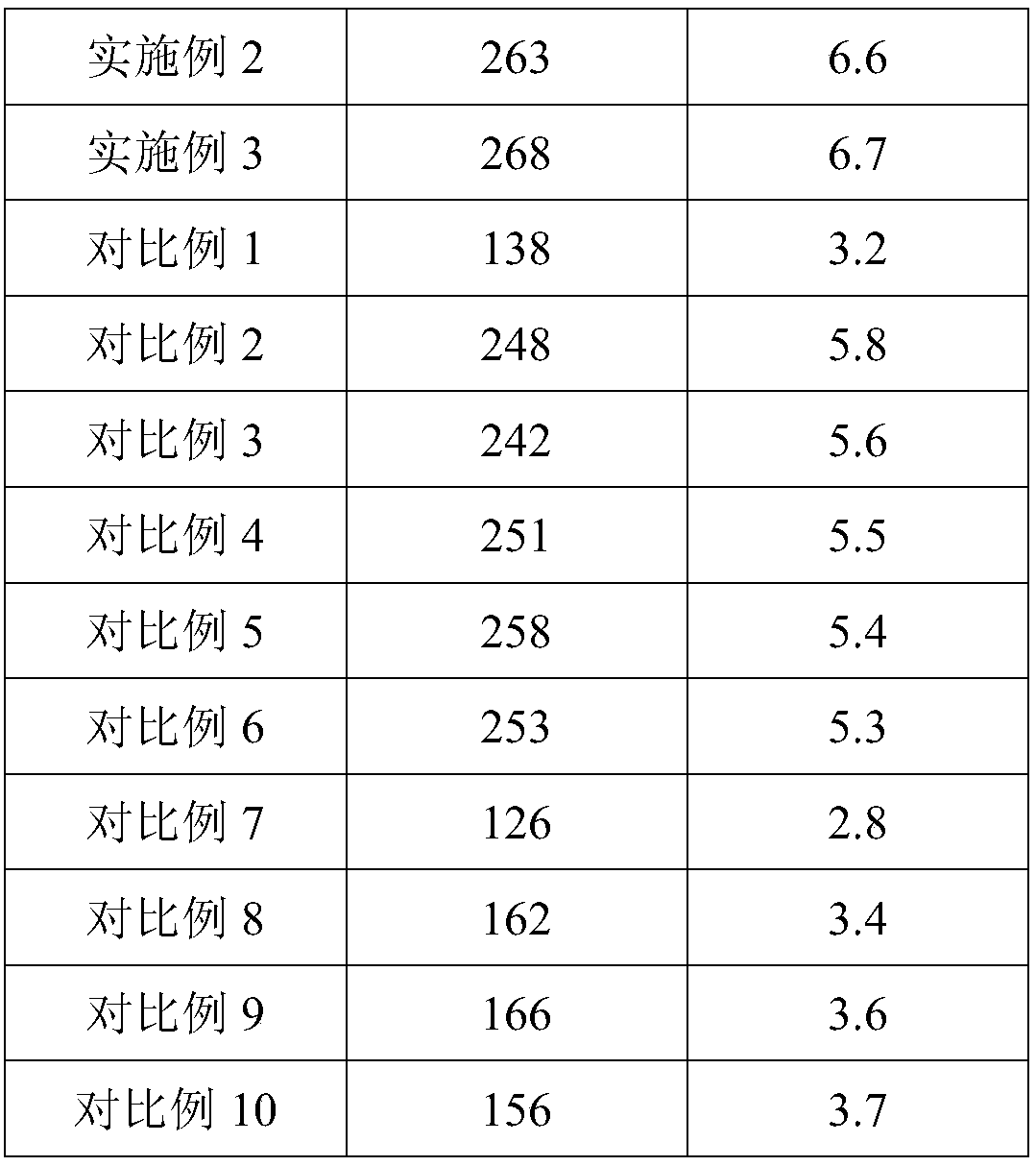

Examples

preparation example Construction

[0026] The preparation method of described fireproof cable comprises the following steps:

[0027] S1. Mix ethylene-propylene rubber, styrene-butadiene rubber and ammonium polyphosphate evenly, heat up to 120-130°C, keep warm for 10-30min, then stir at 1500-2500r / min for 10-30min, cool to room temperature to obtain the base material;

[0028] S2. Mix methylphenyl silicone resin and fluorocarbon resin evenly, heat up to 110-130°C, keep warm for 20-40min, then add silicon dioxide, carbon nanotubes, silicon hydrogen groups, cellulose ether, carbon black N330 , glass fiber, sodium silicate, chlorinated paraffin, simethicone, expanded vermiculite, accelerator TMDT, zinc oxide, stearic acid, antioxidant RD, mix evenly, and stir at 850-1050r / min for 1-2h, Then continue to heat up to 80-90°C, keep warm for 5-15min, then add modified heat-resistant agent and trisilanol phenyl silsesquioxane and mix evenly, stir at 2500-3500r / min for 5-15min, and cool to room temperature obtain modifie...

Embodiment 1

[0031] A fireproof cable, which is composed of a cable core and a protective sheath wrapped outside the cable core, the protective sheath, in parts by weight, includes the following raw materials: 112 parts of ethylene-propylene rubber, 16.5 parts of methyl phenyl silicone resin 9.4 parts of styrene-butadiene rubber, 34.5 parts of fluorocarbon resin, 7.4 parts of ammonium polyphosphate, 7.2 parts of silicon dioxide, 6.2 parts of carbon nanotubes, 5.1 parts of silicon hydrogen group, 6 parts of cellulose ether, carbon black N3305.8 3.4 parts of glass fiber, 3.2 parts of sodium silicate, 7.4 parts of chlorinated paraffin, 2.6 parts of dimethyl silicone oil, 7.8 parts of expanded vermiculite, 10.6 parts of modified heat-resistant agent, trisilanol phenyl silsesquioxane 2.3 parts, accelerator TMDT 5.7 parts, zinc oxide 5.7 parts, stearic acid 4.8 parts, antioxidant RD 4.9 parts.

[0032] The modified heat-resistant agent is prepared according to the following process: mix 9.6 part...

Embodiment 2

[0038] A fireproof cable, which is composed of a cable core and a protective sheath wrapped outside the cable core, the protective sheath, in parts by weight, includes the following raw materials: 100 parts of ethylene-propylene rubber, 25 parts of methyl phenyl silicone resin 8 parts of styrene-butadiene rubber, 40 parts of fluorocarbon resin, 5 parts of ammonium polyphosphate, 9 parts of silicon dioxide, 4 parts of carbon nanotubes, 6 parts of silicon hydrogen group, 1 part of cellulose ether, 9 parts of carbon black N3309, 1 part of glass fiber, 4 parts of sodium silicate, 5 parts of chlorinated paraffin, 3 parts of dimethyl silicone oil, 6 parts of expanded vermiculite, 12 parts of modified heat-resistant agent, 1 part of trisilanol phenyl silsesquioxane , accelerator TMDT 9 parts, zinc oxide 4 parts, stearic acid 6 parts, antioxidant RD 2 parts.

[0039] The modified heat-resistant agent is prepared according to the following process: 8 parts by weight of carbamate, 5 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com