Preparation method and application of composite nanomaterial with aggregation-induced luminescent property and photothermal conversion property

A technology of aggregation-induced luminescence and composite nanomaterials, which is applied in the direction of luminescent materials, chemical instruments and methods, and medical preparations containing active ingredients, etc., which can solve the problems of limited application and incompatibility of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Synthesis of TPE-2

[0045] Structural formula:

[0046]

[0047] Synthesis process see figure 1 The synthetic route shown.

[0048] (1) Synthesis of TPE-002: Take 5mmol of 4,4'-dimethoxybenzophenone and 4,4'-dibromobenzophenone and 40mmol of zinc powder into a 500mL two-necked flask, add magnetic Add 250 mL of anhydrous THF, and freeze-thaw cycle 3 times to remove dissolved oxygen. Slowly add TiCl dropwise to a nitrogen-protected two-necked flask under an ice-acetone bath 4 20mmol. After returning to room temperature naturally, the reaction was heated under reflux for 12 hours. After the reaction was completed, saturated sodium bicarbonate was added dropwise to quench the reaction. The reaction system was suction filtered, and the filtrate was extracted with dichloromethane. The dichloromethane layer was collected, dried with anhydrous sodium sulfate, and separated and purified by column chromatography. The polarity of the eluent was petroleum ...

Embodiment 2

[0051] Embodiment 2: Synthesis of SPC10

[0052] Structural formula:

[0053]

[0054] Synthesis process see figure 2 The synthetic route shown.

[0055] Synthesis of SPC10: Before preparation, dry the long needle, 15mL Shrek reaction tube and magneton in a blast drying oven at 120°C. Weigh 0.2 mmol of dithiophene diketopyrrolopyrrole monomer, 0.2 mmol of cyclopentane dithiophene tin reagent, Pd 2 (dba) 3 0.016mmol, P(o-toly) 3 0.004mmol was added to the reaction tube, and after the reaction tube was replaced with nitrogen, 5.0mL of anhydrous toluene was quickly added, and the dissolved oxygen was removed by freeze-thaw cycles under reduced pressure three times. After the reaction tube returned to room temperature, a nitrogen balloon was stuck on the rubber stopper for protection, the stirring was turned on, covered with tin foil to avoid light, and the temperature was raised to 100°C for 6 hours of reaction. After the reaction was completed and returned to room tem...

Embodiment 3

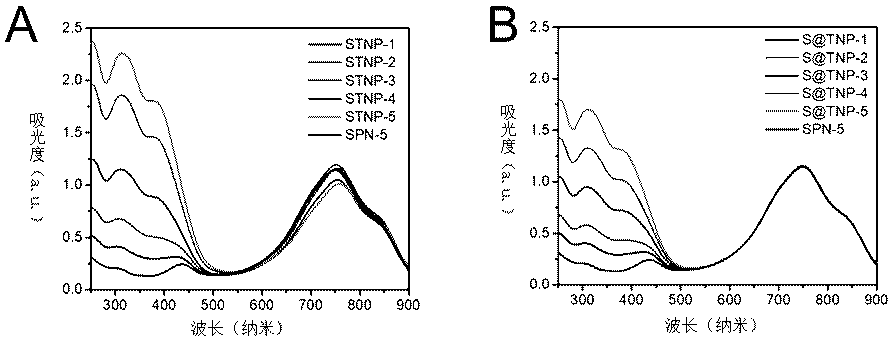

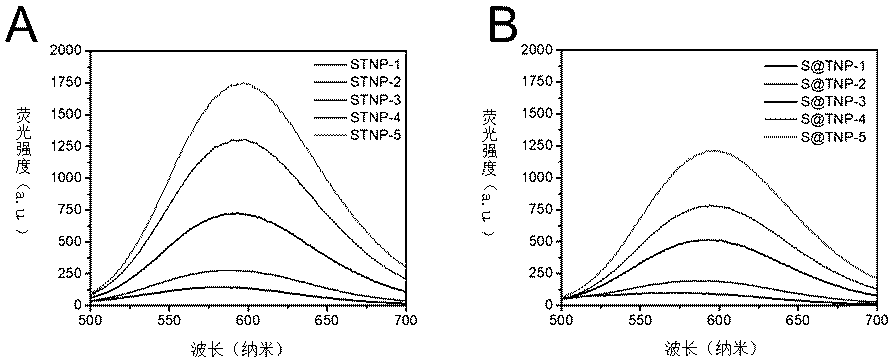

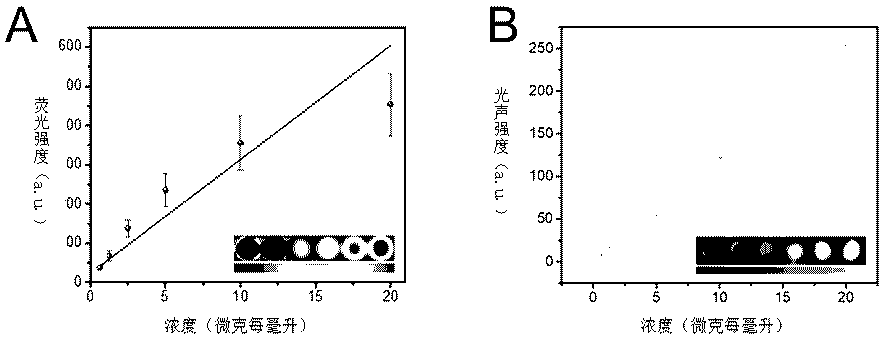

[0056] Example 3: Preparation of composite nanoparticle STNP.

[0057] Preparation method: This preparation method refers to the nano-sedimentation method, which is a commonly used preparation method for nano-organic rice particles, but changes the concentration of the solution and the ratio of the two phases of oil and water. First dissolve SPC10, TPE-2, and F127 in THF at a certain ratio (Table 1), then quickly transfer the organic solution to a large amount of water, and sonicate for 20 minutes. The obtained nanoparticle solution was centrifuged 5 times by ultrafiltration, with a cut-off molecular weight of 3500 Da, a rotating speed of 3500 rpm, and a centrifugation time of 30 minutes; the obtained polymer nanoparticle solution was diluted to 10 milliliters and filtered with a polysulfone ether filter membrane with a pore size of 0.22 microns, and then used Concentrate by ultrafiltration and centrifugation, and finally dilute to 1 mL, and store at 4°C.

[0058] Table 1: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com