Environmentally-friendly recycled paper and preparation method thereof

A recycled paper, environmentally friendly technology, applied in the field of paper manufacturing, can solve the problems of high formaldehyde content and poor waterproof ability of waste paper, and achieve the effect of improving whiteness, improving bonding degree and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

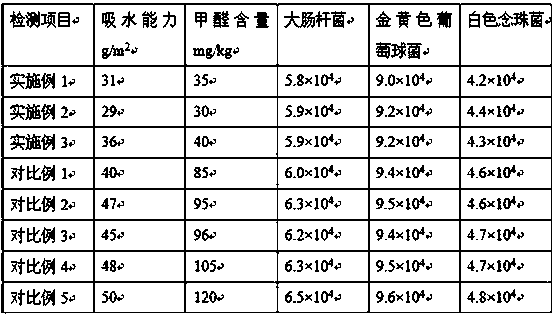

Examples

preparation example Construction

[0028] The preparation method of deinking active agent is:

[0029] Take alkylphenol polyoxyethylene ether and add isophor diisocyanate in a mass ratio of 2~5:3~6, heat up to 60~65°C and stir for 30~40min, then add 5~10% of isophor diisocyanate dropwise The dibutyltin dilaurate is controlled to drop for 20-30 minutes to obtain a mixture. Take the mixture and add acetone according to the mass ratio of 20-30:2-5, and stir and mix at 60-65°C for 1-3 hours to obtain the stirred mixture. Take the stirred mixture Add tartaric acid at a mass ratio of 10~15:3~6, heat up to 100~105°C, stir and mix for 3~5 hours, cool to room temperature, and obtain a deinking active agent.

[0030] The preparation method of waste paper formaldehyde removal additive is:

[0031] (1) Take ethyl acetoacetate according to the mass ratio of 15~20:1~3:40~50, add potassium carbonate and absolute ethanol, heat up to 80~90°C and mix for 30~40min, add ethyl acetoacetate with a mass ratio of 50~ 60% of hydroxyl...

Embodiment 1

[0043] The preparation method of deinking active agent is:

[0044] Take alkylphenol polyoxyethylene ether and add isophor diisocyanate in a mass ratio of 2:3, heat up to 60°C and stir and mix for 30 minutes, then add dibutyltin dilaurate dropwise with 5% isophor diisocyanate mass to control the dropping time After 20 minutes, the mixture was obtained. Take the mixture and add acetone according to the mass ratio of 20:2, stir and mix at 60°C for 1 hour to obtain the stirred mixture, take the stirred mixture and add tartaric acid according to the mass ratio of 10:3, heat up to 100°C, stir and mix for 3 hours, and cool to room temperature , to obtain deinking active agent.

[0045] The preparation method of waste paper formaldehyde removal additive is:

[0046] (1) Take ethyl acetoacetate, add potassium carbonate and absolute ethanol at a mass ratio of 15:1:40, heat up to 80°C and stir and mix for 30 minutes, add hydroxyl-terminated hyperbranched polyester with 50% of the mass ...

Embodiment 2

[0058] The preparation method of deinking active agent is:

[0059] Take alkylphenol polyoxyethylene ether and add isophor diisocyanate in a mass ratio of 5:6, heat up to 65°C and stir and mix for 40 minutes, then add dibutyltin dilaurate dropwise with 10% isophor diisocyanate mass to control the dropping time 30min to get the mixture, take the mixture and add acetone according to the mass ratio of 30:5, stir and mix at 65°C for 3h to obtain the stirred mixture, take the stirred mixture and add tartaric acid according to the mass ratio of 15:6, heat up to 105°C, stir and mix for 5h, and cool to room temperature , to obtain deinking active agent.

[0060] The preparation method of waste paper formaldehyde removal additive is:

[0061] (1) Take ethyl acetoacetate, add potassium carbonate and absolute ethanol at a mass ratio of 20:3:50, heat up to 90°C and stir and mix for 40 minutes, add hydroxyl-terminated hyperbranched polyester with 60% mass of ethyl acetoacetate, and then h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com