A method for preparing a diaphragm for high-safety, high-energy-density lithium-ion batteries

A high-energy density, lithium-ion battery technology, applied in battery pack components, separators/films/diaphragms/spacers, circuits, etc. Large-scale equipment is required to achieve the effect of good wettability, low equipment requirements, and uniform pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

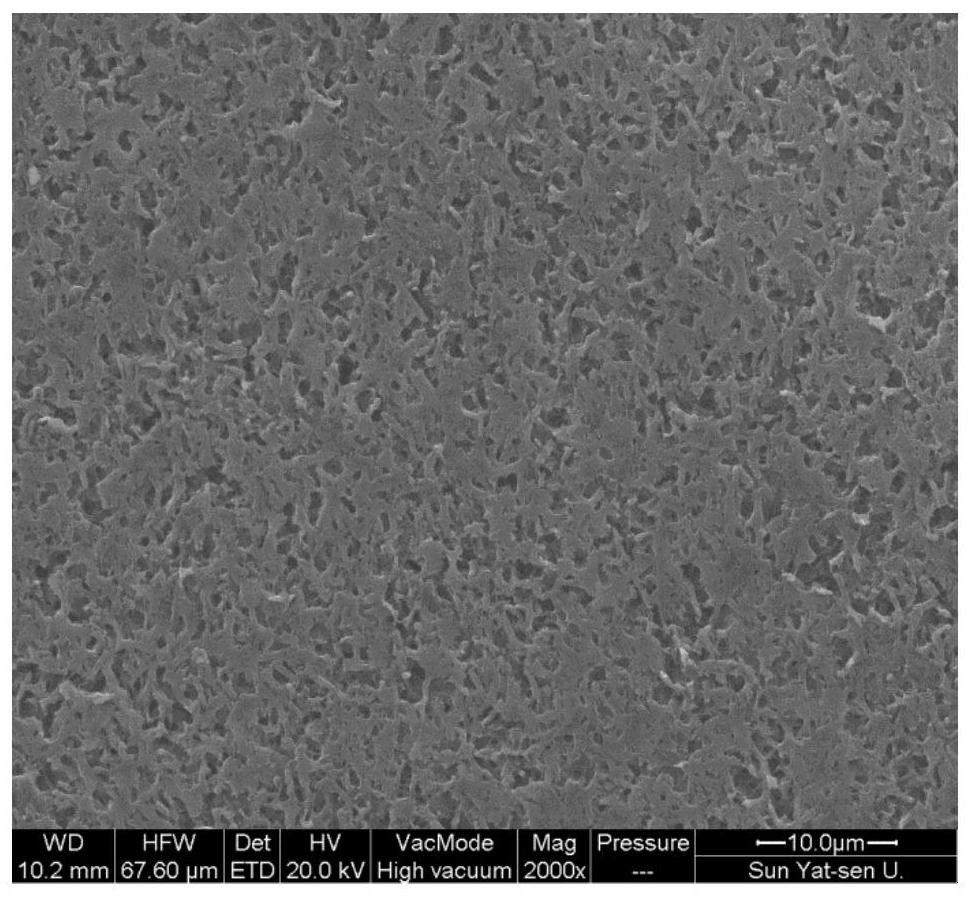

[0030] Weigh 4g of polyphenylene sulfide resin, 9g of diphenylsulfone and 3g of polyethersulfone and blend them in a quartz bottle, heat to 250°C under nitrogen protection, and mechanically stir for 20min to obtain polyphenylene sulfide, diphenylsulfone and A blended solution of polyethersulfone (wherein the mass fraction of polyphenylene sulfide is 25%, and the mass ratio of the first diluent diphenyl sulfone and the second diluent polyethersulfone is 3:1). Then pour the blended solution into an ice-water bath to obtain a blended solid of the three, which is pulverized into powder particles with a pulverizer. Weigh 0.75g of powder sample, place it in a 40μm thick polyimide mold (area: 7cm×8cm), and use a flat vulcanizer to press at 4MPa and 250°C for 3min to obtain polyphenylene sulfide and diphenyl sulfone and polyethersulfone blend films. Finally, dimethyl sulfoxide was used to extract the diphenyl sulfone and polyether sulfone for 12 hours, and the extractant was evaporat...

Embodiment 2

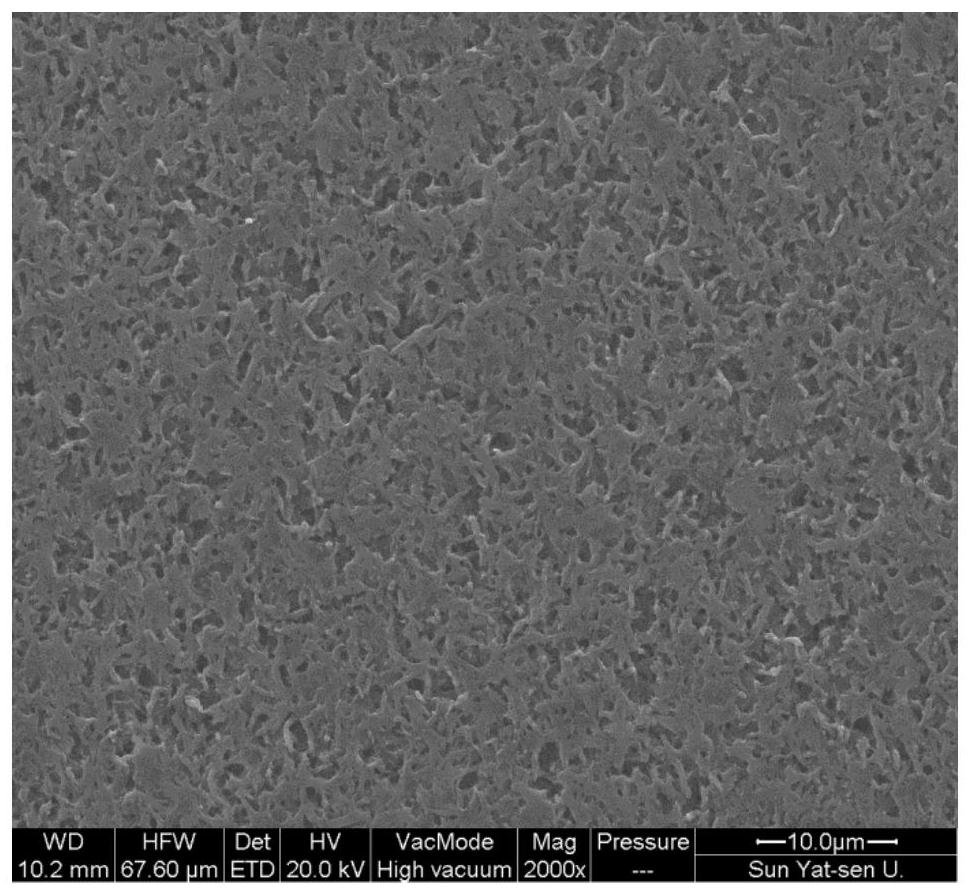

[0032] Weigh 4g of polyphenylene sulfide resin, 10g of diphenyl sulfone and 2g of polyether sulfone blend, wherein the mass fraction of polyphenylene sulfide is 25%, the mass ratio of the first diluent diphenyl sulfone and the second diluent polyether sulfone The ratio is 5:1, and other experimental steps are the same as in Example 1 to prepare a polyphenylene sulfide porous membrane (diaphragm A2).

Embodiment 3

[0034] Weigh 3g of polyphenylene sulfide resin, 8g of diphenyl sulfone and 1g of polyether sulfone blend, wherein the mass fraction of polyphenylene sulfide is 25%, the mass ratio of the first diluent diphenyl sulfone and the second diluent polyether sulfone The ratio is 8:1, and other experimental steps are the same as in Example 1 to prepare a polyphenylene sulfide porous membrane (diaphragm A3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com