Preparation of high-performance ZnS @ SiO2/C cathode and lithium/sodium storage application of cathode

A high-performance, negative-electrode technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of high raw material and technology costs, lack of mechanical stability and durability, structural damage, etc. Sustainable development prospects and research value, stable electrochemical performance and high reversibility, and the effect of realizing waste resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

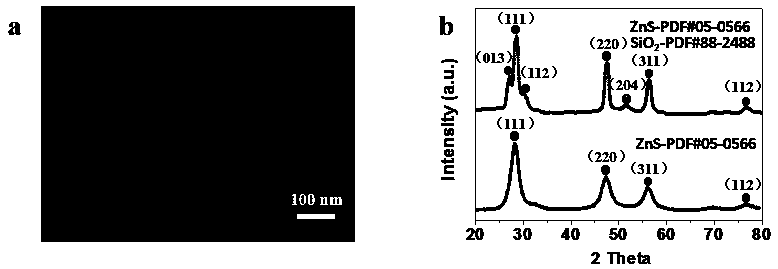

[0034] Example 1 ZnS@SiO 2 Synthesis of / C anode materials

[0035] (1) ZnS@Si(OH) 4 Synthesis of precursors: ultrasonically dissolve zinc salts and organic salts in deionized water, add a small amount of waste glass fragments, stir and react in a heated water bath, the solution changes from colorless and transparent to white suspension, and after cooling, use deionized Washing with water, filtering and drying to obtain the precursor powder;

[0036] (2) ZnS@SiO 2 Synthesis of / C anode material: ZnS@Si(OH) prepared in step (1)(a) 4 The precursor powder was evenly distributed inside the crucible, and then the crucible was placed in the middle area of the quartz tube furnace, and under the protection of a nitrogen atmosphere, the o Cmin -1 The heating rate increases to 900 o C. At this time, the ethanol saturated steam is slowly introduced into the inlet valve, and the ethanol gas is quickly brought to the central area of the tube furnace by the air flow and continues to...

Embodiment 2

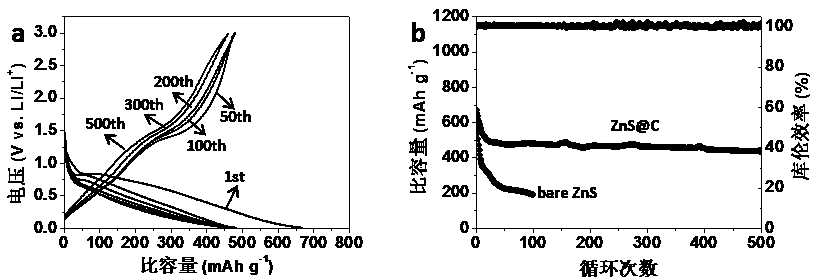

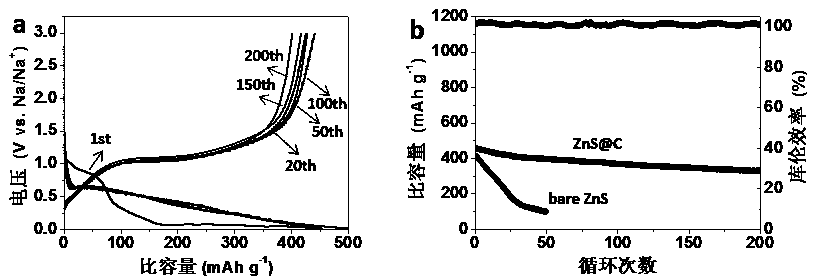

[0038] Example 2 uses ZnS@SiO 2 Production and testing method of lithium / sodium storage battery with / C as negative electrode

[0039] (1) Preparation of negative electrode sheet: ZnS@SiO obtained in step (1) 2 / C Powder material, conductive agent, binder are fully ground in a ball mill with an organic solvent in a mass ratio of 8:1:1, and then the resulting slurry is evenly coated on a copper foil with a scraper, and it is obtained after vacuum baking ZnS@SiO 2 / C negative plate;

[0040] (2) Half-cell assembly and performance testing: ZnS@SiO 2 / C Negative plate is transferred to the glove box and packaged with CR 2025 button battery case;

[0041] (a) For the lithium storage half-cell test, the lithium sheet was used as the counter electrode, and the Celgard 2500 type polypropylene film was used as the separator, dissolved with 1 M LiPF 6 And the EC / DEC mixture with a volume ratio of 1:1 is used as the electrolyte;

[0042] (b) For the sodium storage half-cell test, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com