Processing technic for tetrastigma hemsleyanum diels et gilg

A processing technology, the technology of cloverleaf, applied in the field of cloverleaf processing technology, can solve the problems that cloverleaf is not targeted, fully absorbed, and the medicinal properties cannot be maintained for a long time, and achieve the effect of preventing bacterial reproduction and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

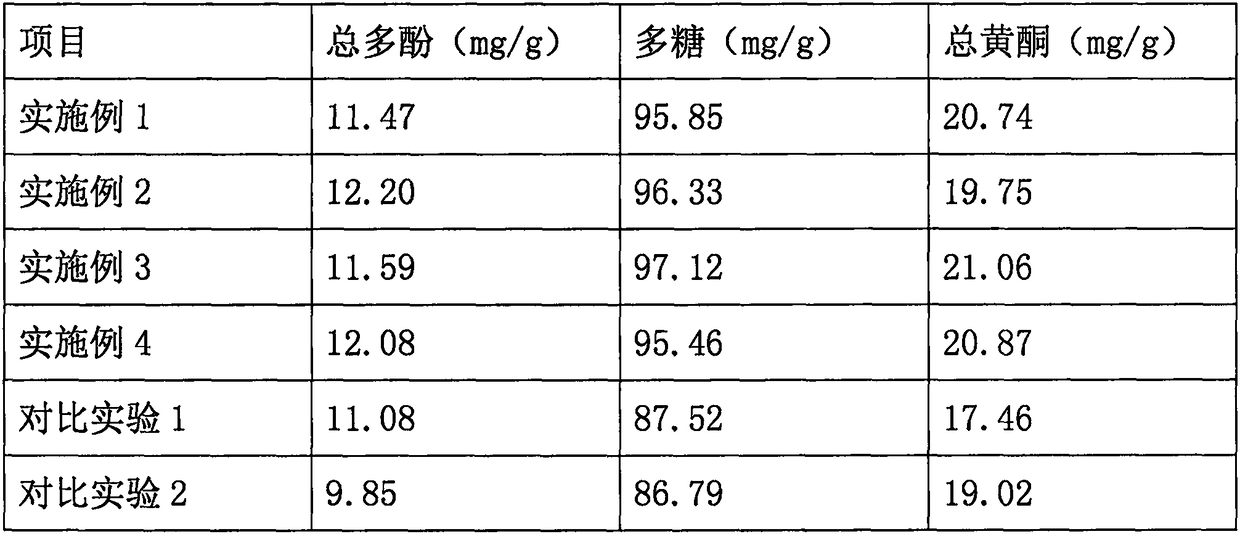

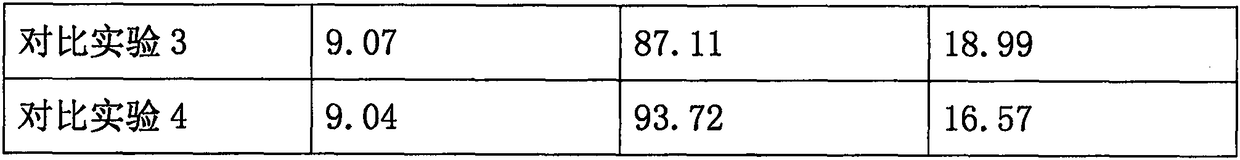

Examples

Embodiment 1

[0020] The parts by weight of the various parts of A. trilobata in the present embodiment are: 60 parts of A. clover leaves, 17 parts of stems, 30 parts of tubers, and 9 parts of fruits.

[0021] The processing technology of Clover in the present embodiment comprises the following steps: get the stem of Clover, wash, dry naturally, be ground into 80 mesh powders, put into the there-necked bottle of reflux device, add sherwood oil, reflux, Reaction condition is 70 ℃, reflux 5 times, each 130min, then use nylon gauze to filter out the stem filter residue of Clover; after cleaning the leaves of Clover, add water to grind and pulverize, filter, and the mesh size of the sieve is 130 mesh, the filtrate is ready for use; take the root tuber of Clover, dry it in a neon gas atmosphere, and cut it into thin slices with a thickness of 3.8 mm after cooling; dry the root slices again at 82°C under a nitrogen atmosphere for 30 minutes, and take out after cooling , then carry out microwave h...

Embodiment 2

[0024] The parts by weight of the various parts of A. trilobata in the present embodiment are: 65 parts of A. clover leaves, 15 parts of stems, 25 parts of tubers, and 7 parts of fruits.

[0025] The processing technology of Clover in the present embodiment, comprises the following steps: get the stem of Clover, wash, dry naturally, be ground into 40 mesh powders, put into the there-necked bottle of reflux device, add sherwood oil, reflux, Reaction condition is 70 DEG C, reflux 5 times, each 135min, then use nylon gauze to filter out the stem filter residue of Clover; After cleaning the leaves of Clover, add water to grind and pulverize, filter, and the mesh size of the sieve is 120 mesh, the filtrate is ready for use; take the root tuber of Clover, dry it in a neon gas atmosphere, and cut it into thin slices with a thickness of 4.2 mm after cooling; dry the root slices again at 85°C under a nitrogen atmosphere for 35 minutes, and take out after cooling , then carry out microw...

Embodiment 3

[0028] The parts by weight of the various parts of A. trilobata in the present embodiment are: 70 parts of A. clover leaves, 25 parts of stems, 35 parts of tubers, and 12 parts of fruits.

[0029] The processing technology of Clover in the present embodiment, comprises the following steps: get the stem of Clover, wash, dry naturally, be ground into 60 mesh powders, put into the there-necked bottle of reflux device, add sherwood oil, reflux, Reaction condition is 70 DEG C, reflux 5 times, each 135min, then use nylon gauze to filter out the stem filter residue of Clover; After cleaning the leaves of Clover, add water to grind and pulverize, filter, and the mesh size of the sieve is 110 mesh, the filtrate is ready for use; take the root tubers of Clover, dry them in a neon gas atmosphere, and cut them into thin slices with a thickness of 4.0 mm after cooling; dry the root slices again at 90°C under a nitrogen atmosphere for 38 minutes, and take them out after cooling , then carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com