Method for preparing geopolymer rubber composite material by utilizing spent FCC (fluid catalytic cracking) catalyst

A technology of geopolymer and waste catalyst, applied in the field of solid waste resource utilization, can solve the problems of high brittleness, environmental pollution, energy waste, etc., and achieve the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

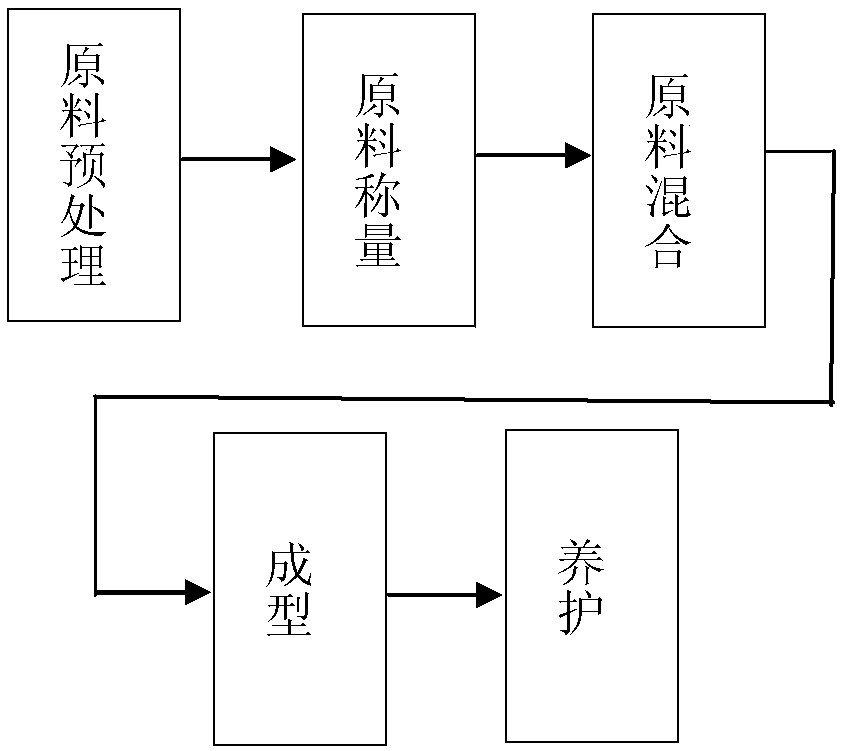

Method used

Image

Examples

Embodiment 1

[0037] The geopolymer rubber composite material is prepared from FCC waste catalyst, and the mass ratio of ultrafine FCC waste catalyst powder, ultrafine fly ash, waste rubber powder, and sodium silicate is 40:20:15:30; wherein, ultrafine FCC The spent catalyst powder is made by ball milling of FCC spent catalyst, and its specific surface area is 325m 2 / kg, 28 days activity index 95%; superfine fly ash is made by ball milling of fly ash, its specific surface area is 550m 2 / kg, 28-day activity index 98%; waste rubber powder is mechanically processed and pulverized from waste rubber tires, with a particle size of 30 mesh; add an appropriate amount of water to the above mixture, and prepare geopolymer rubber compound by stirring, molding and curing Material.

[0038] The leaching concentration of nickel element of the prepared geopolymer rubber composite material was reduced from 9.6mg / L to 1.5mg / L, the leaching toxicity of V element was reduced from 18.2mg / L to 3.2mg / L, and th...

Embodiment 2

[0040] The geopolymer rubber composite material is prepared from FCC waste catalyst, and the mass ratio of ultrafine FCC waste catalyst powder, ultrafine fly ash, waste rubber powder, and sodium hydroxide is 60:10:10:20; wherein, ultrafine FCC The spent catalyst powder is made by ball milling of FCC spent catalyst, and its specific surface area is 425m 2 / kg, 28 days activity index 98%; superfine fly ash is made by ball milling of fly ash, its specific surface area is 600m 2 / kg, 28 days activity index 98%; waste rubber powder is to be pulverized by waste rubber tire mechanical processing, and particle size is 40 orders; Add the water that quality is 0.4 of the total mass of above-mentioned mixture to above-mentioned mixture, through stirring, molding, The geopolymer rubber composite was prepared by curing.

[0041] The leaching concentration of nickel element in the prepared geopolymer rubber composite material was reduced from 9.6mg / L to 0.98mg / L, the leaching toxicity of V...

Embodiment 3

[0043] Prepare geopolymer rubber composite material by FCC waste catalyst, the mass ratio of ultrafine FCC waste catalyst powder, ultrafine fly ash, waste rubber powder, water glass is 50:15:10:30; Wherein, ultrafine FCC waste The catalyst powder is made by ball milling of FCC waste catalyst, and its specific surface area is 450m 2 / kg, 28 days activity index 90%; superfine fly ash is made by ball milling of fly ash, its specific surface area is 600m 2 / kg, 28 days activity index 90%; waste rubber powder is machined and pulverized by waste rubber tires, particle size is 50 mesh; the chemical formula of water glass is R 2 O nSiO 2 , wherein R is Na or K, and n is 0.8-2.0; adding water with a mass of 0.45% of the total mass of the above mixture to the above mixture, and preparing a geopolymer rubber composite material through stirring, molding and curing.

[0044] The leaching concentration of nickel element of the prepared geopolymer rubber composite material was reduced from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com