Production method of biological charcoal based slow-release compound fertilizer

A slow-release compound fertilizer and biochar technology, applied in chemical instruments and methods, nitrogen fertilizers, potash fertilizers, etc., can solve the problems of poor application effect and single nutrient elements, and achieve the effects of low cost, abundant resources, and improved fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

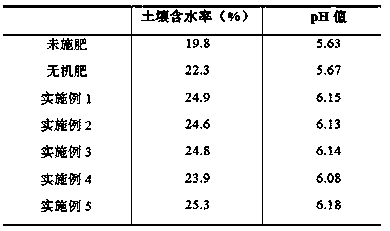

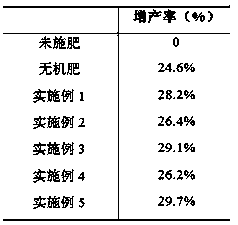

Examples

Embodiment 1

[0027] A biochar-based slow-release compound fertilizer and a production method thereof, the specific steps are as follows:

[0028] (1) Dry the crop stalks as the biomass raw material at 70° C., and crush them to a particle size of 1 mm.

[0029] (2) Mix the above-mentioned biomass raw material with a mixed activator, and soak for 2 hours. The mixed activator is a combination of three agents including ammonium chloride, phosphoric acid, and potassium sulfate. The mass ratio of the three agents to the biomass raw material is It is 2:0.8:0.6:1.

[0030] (3) After the impregnated biomass was heated and dried, it was carbonized in a protective atmosphere at 200°C for 1 hour, and then activated in a protective atmosphere at 500°C for 4 hours, with a heating rate of 10°C / min.

[0031] (4) Cool the activated biomass to room temperature under a protective atmosphere (water vapor) to obtain the product.

Embodiment 2

[0033] A biochar-based slow-release compound fertilizer and a production method thereof, the specific steps are as follows:

[0034] (1) Dry the biomass raw materials (wood chips and bagasse) at 80°C and crush them to a particle size of 2mm.

[0035] (2) Mix the above-mentioned biomass raw material with a mixed activator, and soak for 5 hours; the mixed activator is a combination of three agents including ammonium chloride, phosphoric acid, and potassium sulfate, and the mass ratio of the three agents to the biomass raw material is It is 1:0.4:0.3:1.

[0036] (3) After the impregnated biomass was heated and dried, it was carbonized in a protective atmosphere at 300°C for 2 hours, and then activated in a protective atmosphere at 600°C for 3 hours, with a heating rate of 12°C / min.

[0037] (4) Cool the activated biomass to room temperature under a protective atmosphere (water vapor and carbon dioxide) to obtain the product.

Embodiment 3

[0039] A biochar-based slow-release compound fertilizer and a production method thereof, the specific steps are as follows:

[0040] (1) Dry the biomass raw material (straw) at 120°C and crush it to a particle size of 5mm.

[0041] (2) Mix the above-mentioned biomass raw materials with a mixed activator, and soak for 12 hours. The mixed activator is a combination of ammonium chloride and phosphoric acid, and the mass ratio of the two kinds of medicaments to the charcoal is 4:2:1 .

[0042] (3) After the impregnated biomass was heated and dried, it was carbonized in a protective atmosphere at 400°C for 3 hours, and then activated in a protective atmosphere at 700°C for 2 hours, with a heating rate of 15°C / min.

[0043] (4) Cool the activated biomass to room temperature under a protective atmosphere (nitrogen) to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com