Preparation method of instant flat peach slices

A flat peach and slicing technology, which is applied in food preservation, fruit and vegetable fresh-keeping, food science, etc., can solve the problems of single deep processing means, high water content, high sugar content of flat peach fruit, etc., to solve the problem of easy deterioration and rot, increase economic added value, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

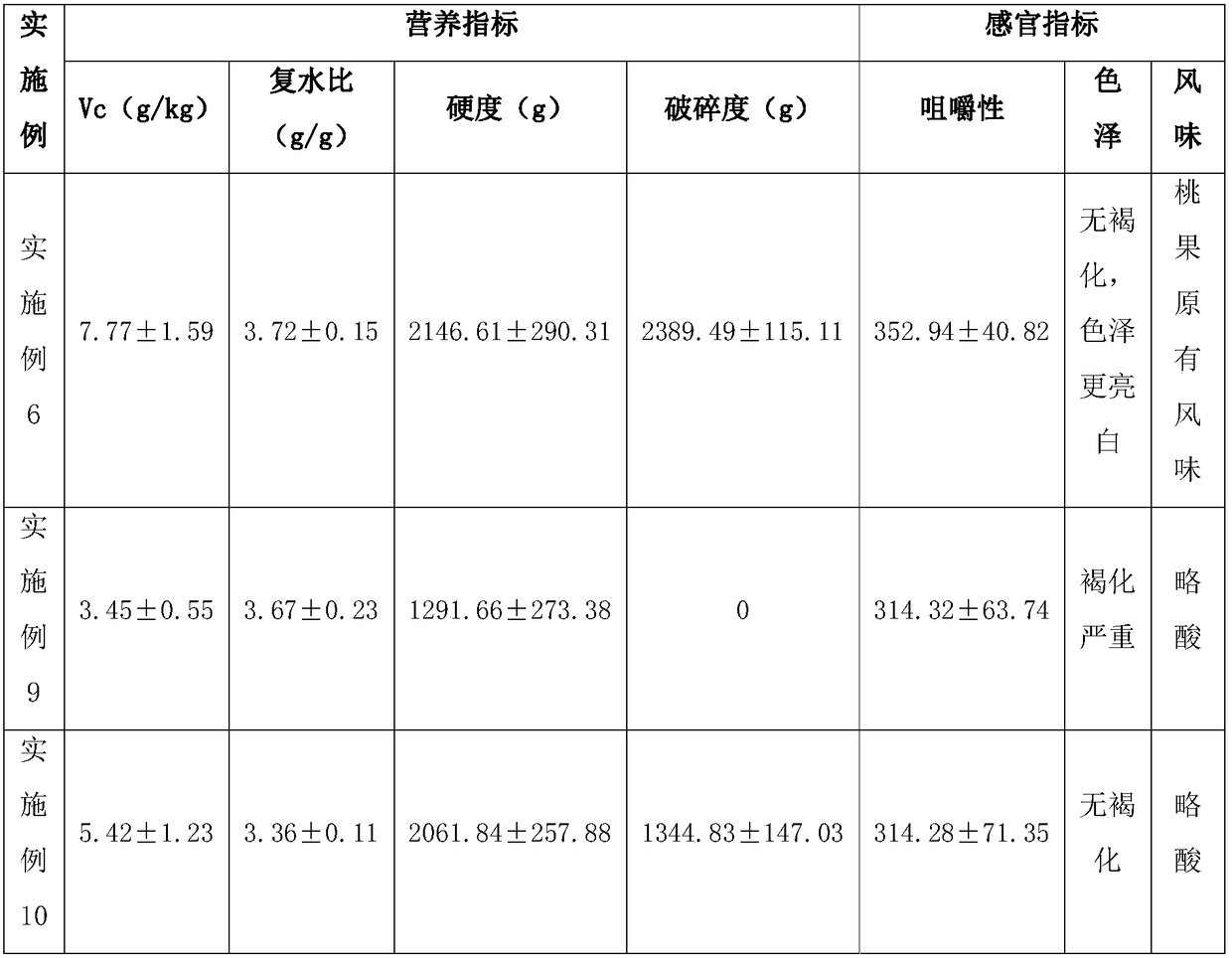

Examples

Embodiment 1

[0031] Embodiment 1: This embodiment 1 discloses a preparation method for preparing flat peach slices. The flat peaches are washed and dried, cored and cut into 5 mm thick slices, and then the cut flat peach slices are immersed in the color protection solution to protect the color 30min, the color-protecting solution is 0.15% by weight of ascorbic acid, 0.6% by weight of citric acid, 0.33% by weight of sodium chloride and the rest of the ultra-pure water, placed in the environment of -25 ° C after color protection Freeze for 11 hours, and finally put it into a vacuum freeze-drying chamber. The temperature of the cold trap is -45°C, the vacuum degree is 15Pa, and the freeze-drying time is 11 hours. After that, the finished peach crisps are obtained. The prepared peach crisps are vacuum-packed to obtain The flat peach slices are crispy in texture, retain the original flavor of fresh peach fruit, and have no browning, and the color is brighter and whiter.

Embodiment 2

[0032] Embodiment 2: This embodiment 2 discloses a preparation method for preparing flat peach slices. The flat peaches are washed and dried, cored and cut into 4mm thick slices, and then the cut flat peach slices are immersed in the color protection solution to protect the color 20min, the color protection solution is 0.1% by weight of ascorbic acid, 0.45% by weight of citric acid, 0.28% by weight of sodium chloride and the rest of the ultrapure water, after color protection, placed in -15 ° C environment Freeze for 12 hours, and finally put it into a vacuum freeze-drying chamber. The temperature of the cold trap is -47°C, the vacuum degree is 10Pa, and the freeze-drying time is 12 hours. After that, the finished peach crisps are obtained. The prepared peach crisps are vacuum-packed to obtain The flat peach slices are crispy in texture, retain the original flavor of fresh peach fruit, and have no browning, and the color is brighter and whiter.

Embodiment 3

[0033] Embodiment 3: This embodiment 3 discloses a preparation method for preparing flat peach slices. Wash and dry the flat peaches, remove the core and cut them into 6mm thick slices, and then immerse the cut flat peach slices in the color protection solution to protect the color 25min, the color-protecting solution is 0.14% by weight of ascorbic acid, 0.5% by weight of citric acid, 0.3% by weight of sodium chloride and the rest of the ultrapure water, placed in the environment of -20 ° C after color protection Freeze for 9 hours, and finally put it into a vacuum freeze-drying chamber. The temperature of the cold trap is -46°C, the vacuum degree is 20Pa, and the freeze-drying time is 10 hours. After that, the finished peach crisps are obtained. The prepared peach crisps are vacuum-packed to obtain The flat peach slices are crispy in texture, retain the original flavor of fresh peach fruit, and have no browning, and the color is brighter and whiter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com