Method of homogeneous titanium dioxide-tin dioxide composite material

A technology of tin dioxide and titanium dioxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, water treatment of special compounds, etc., can solve the problems that cannot be designed, can not really achieve synergy, and achieve Performance optimization, avoiding phase separation problems, and the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

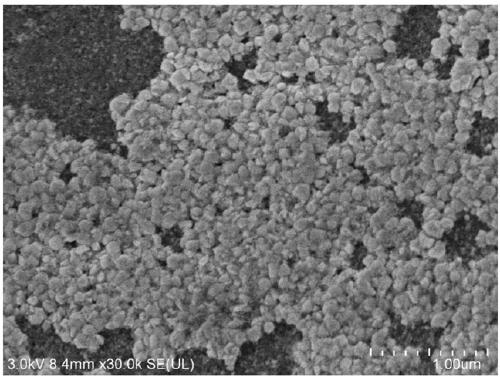

[0032] In 60 mL of ethanol solution, add 1.13 g of stannous chloride dihydrate and 1.65 g of p-carboxybenzylmethoxim powder. The reaction temperature of reflux heating is controlled at 90-100°C, and the reaction time is 6 hours. After the reaction is completed, rotary evaporation is carried out. The rotary evaporation temperature is 50-70°C. The powder obtained after rotary evaporation is placed in a vacuum drying oven. The drying time is After 6 hours, tin dioxide-p-carboxybenzyl oxime powder was obtained. In the state that the double row tube system is filled with inert gas, add 25mL of ethanol solvent, 0.35mL of tetrabutyl titanate and 0.447g of tin dioxide-p-carboxybenzoxime powder. Magnetic stirring reaction for 2-3 hours, after the reaction is completed, the above mixed solution is uniformly dripped on the glass plate, and the solution is hydrolyzed into powder, which can be scraped off with a blade to obtain SnO 2 :TiO 2 =1:1 single-source precursor xerogel powder, an...

Embodiment 2

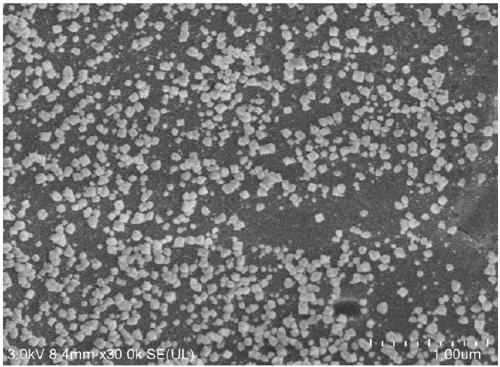

[0034]In 40 mL of ethanol solution, add 1.13 g of stannous chloride dihydrate and 1.65 g of p-carboxybenzylmethoxim powder. The reaction temperature of reflux heating is controlled at 90-100°C, and the reaction time is 6 hours. After the reaction is completed, rotary evaporation is carried out. The rotary evaporation temperature is 50-70°C. The powder obtained after rotary evaporation is placed in a vacuum drying oven. The drying time is After 6 hours, tin dioxide-p-carboxybenzyl oxime powder was obtained. In the state that the double row tube system is filled with inert gas, add 50mL of ethanol solvent, 1.38mL of tetrabutyl titanate and 0.8984g of tin dioxide-p-carboxybenzoximine powder. Magnetic stirring reaction for 2-3 hours, after the reaction is completed, the above mixed solution is uniformly dripped on the glass plate, and the solution is hydrolyzed into powder, which can be scraped off with a blade to obtain SnO 2 :TiO 2 =1:2 single-source precursor xerogel powder, ...

Embodiment 3

[0036] In 40 mL of ethanol solution, add 1.13 g of stannous chloride dihydrate and 1.65 g of p-carboxybenzylmethoxim powder. The reaction temperature of reflux heating is controlled at 90-100°C, and the reaction time is 6 hours. After the reaction is completed, rotary evaporation is carried out. The rotary evaporation temperature is 50-70°C. The powder obtained after rotary evaporation is placed in a vacuum drying oven. The drying time is After 6 hours, tin dioxide-p-carboxybenzyl oxime powder was obtained. In the state that the double row tube system is filled with inert gas, add 50mL of ethanol solvent, 1.38mL of tetrabutyl titanate and 0.8984g of tin dioxide-p-carboxybenzoximine powder. Magnetic stirring reaction for 2-3 hours, after the reaction is completed, the above mixed solution is uniformly dripped on the glass plate, and the solution is hydrolyzed into powder, which can be scraped off with a blade to obtain SnO 2 :TiO 2 =1:2 single-source precursor xerogel powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com