Technology suitable for automatically welding high-strength pressure steel pipes in water tunnel

A penstock and water tunnel technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as insufficient plasticity and low-temperature impact toughness, low welding quality and aesthetics, complex and changeable construction environment, etc., to reduce Effects of lack of fusion, stable welding process performance, and reduction of the probability of occurrence of lack of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

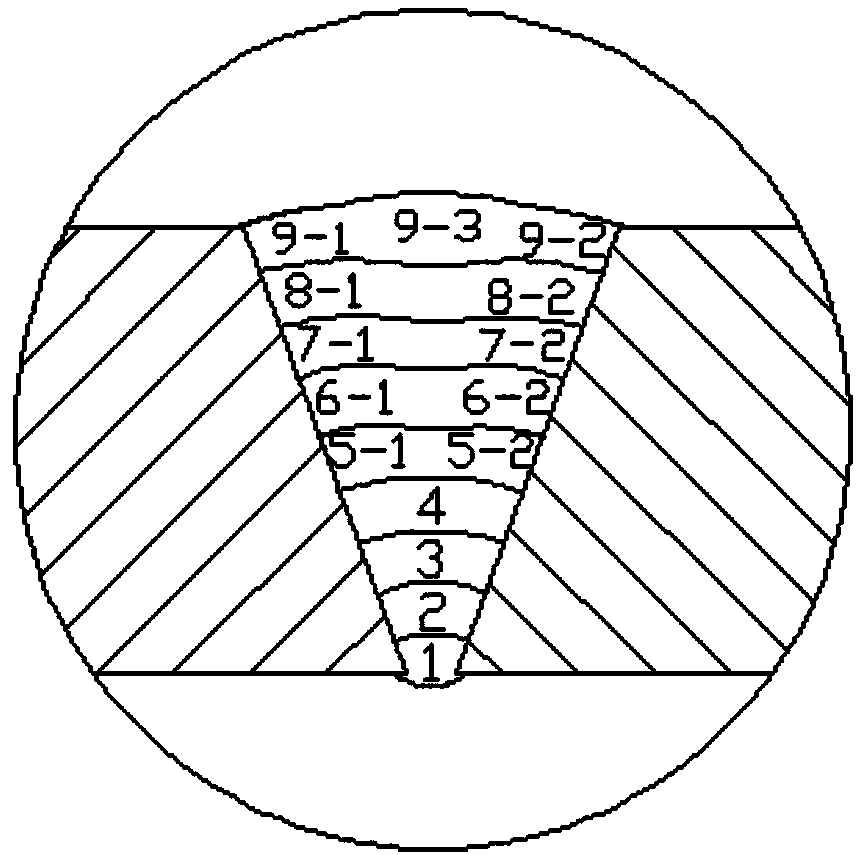

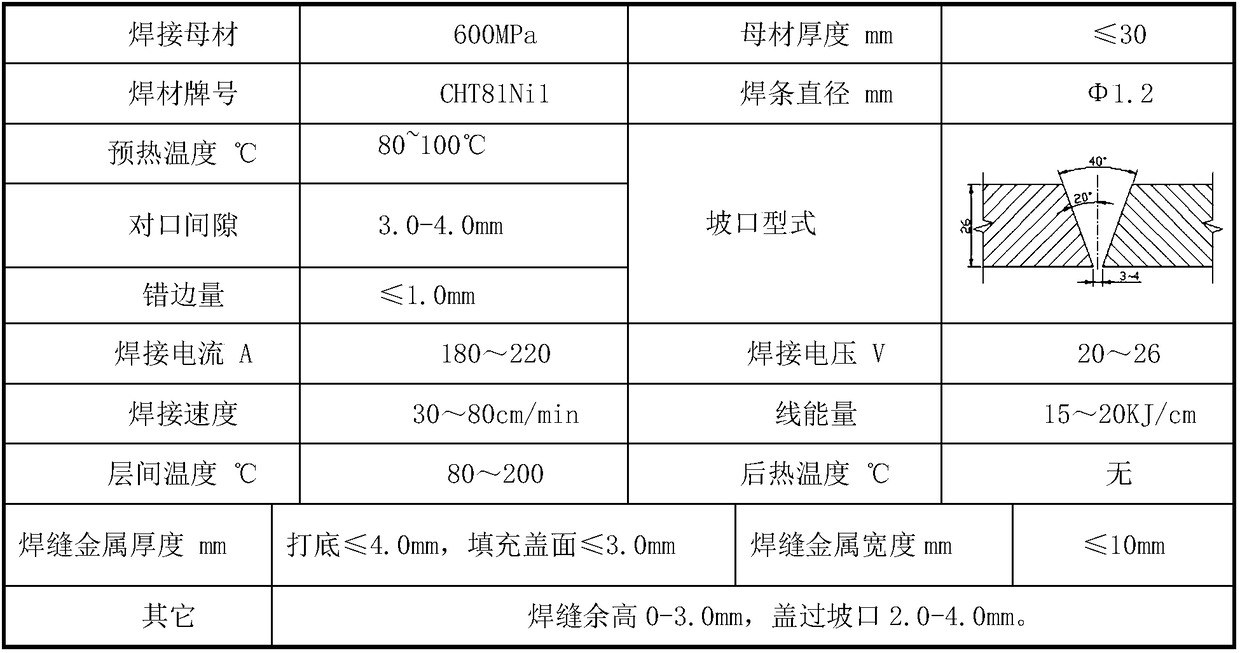

[0030] Embodiment: It is suitable for the process of automatic welding of high-strength pressure steel pipes in water tunnels. The welding object is a steel pipe with a diameter of 4.8m, a plate thickness of 26mm, and a material of 600Mpa. The overall welding equipment consists of a welding trolley, a remote control box, a track, and a welding power supply. Cooling water tank, camera monitoring system. The welding trolley runs stably, the speed is adjustable from 50-1200mm / min, the swing speed and width are adjustable, and the angle of the welding torch is adjustable within plus or minus ten degrees. Flux-cored welding wire matching the base metal of 60KG grade, grade CHT81Ni1 (Atlantic welding consumables, GB / T17493E551T1-Ni1C) or grade GFR-X80-O (Jinglei welding consumables, GB / T17493E551T8-Ni2), diameter 1.2 mm, the extension length of the welding wire is in the range of 15-20mm.

[0031] Include the following steps:

[0032] a. The annulus of the two steel pipes to be we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com