Coal mining water treatment chemical and coal mining water treatment method thereof

A water treatment and coal mine technology, applied in mining wastewater treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing pipeline renewal costs, inhibiting scaling and corrosion, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

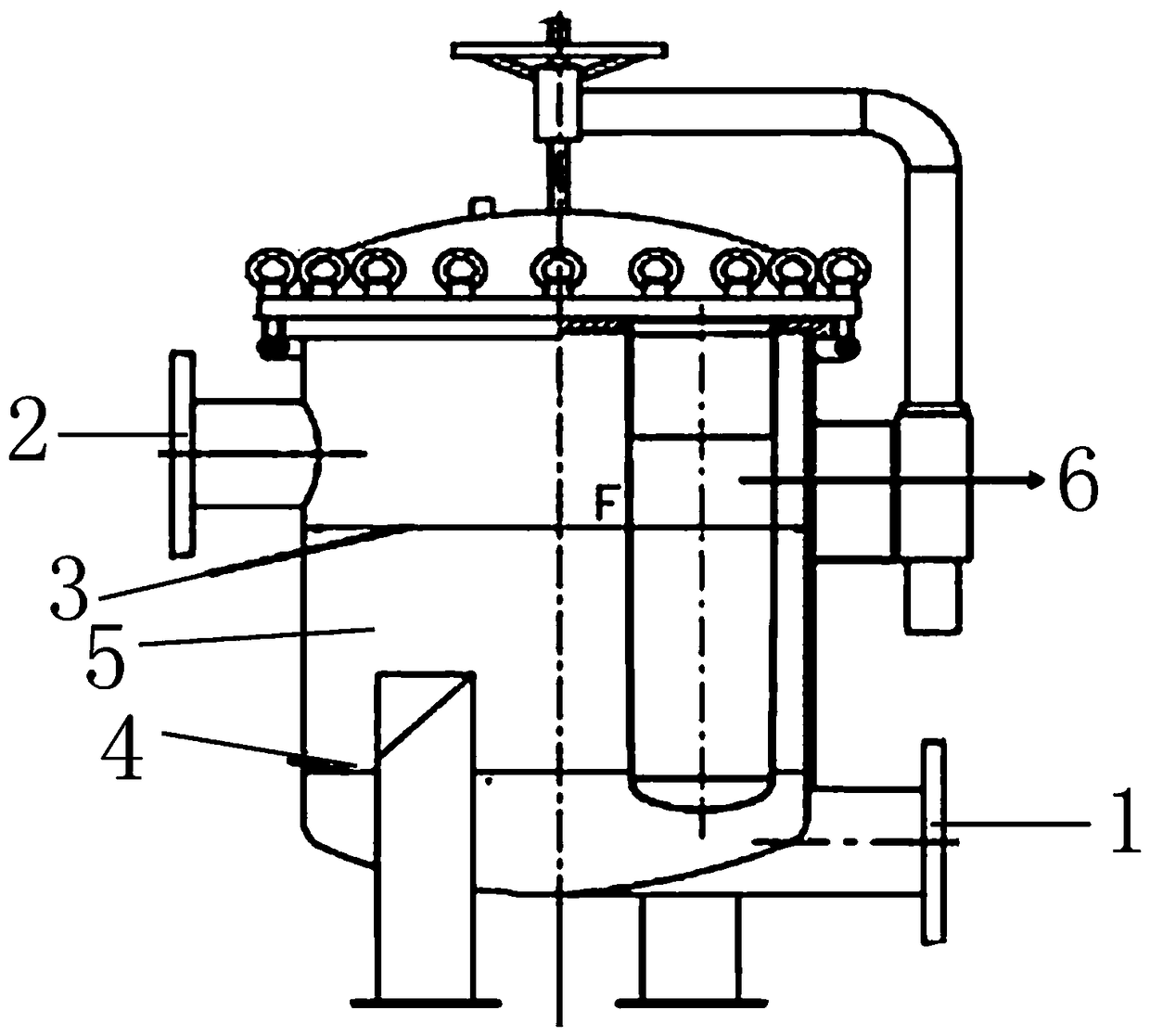

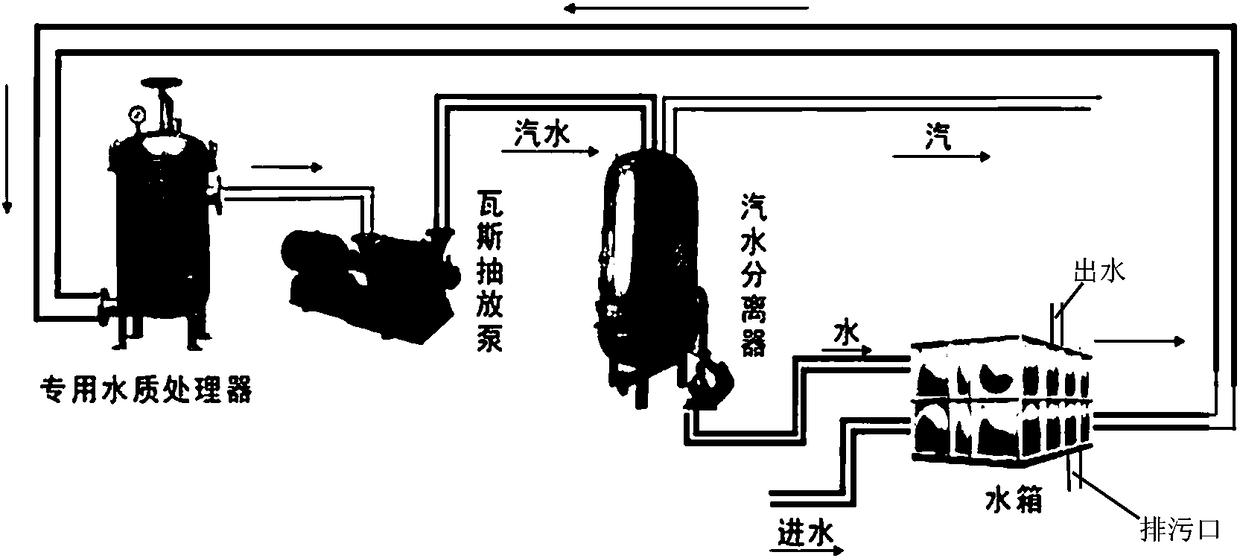

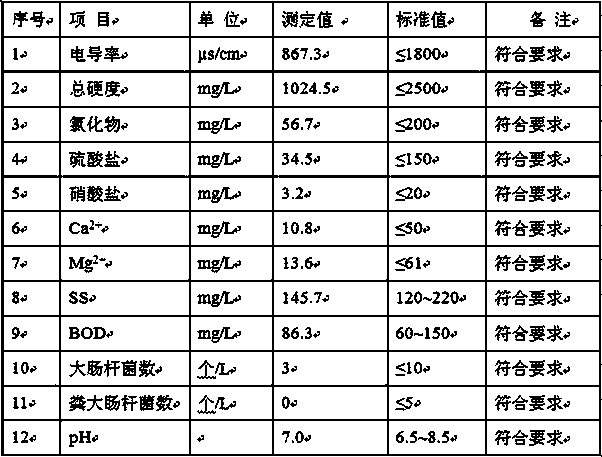

Image

Examples

Embodiment Construction

[0017] A coal mining water treatment agent, prepared from the following raw materials in weight percentage: 1.0 wt% solid stearyl imidazoline silver acetate, 1.0 wt% solid potassium ferrate, 10.0 wt% solid sodium dihydroxyethylglycinate, 10.0 wt% solid sodium 2-oxyacetoxymalonate, 13.0 wt% solid potassium molybdate, 10.0 wt% solid 2-propargylmercaptobenzimidazole, 25.0 wt% solid sodium hexamethylenetetramine diacetate, Viscous fluid melamine formaldehyde resin 30.0 wt%; wherein: stearyl imidazoline silver acetate and potassium ferrate are fungicides; sodium bishydroxyethylglycinate and sodium 2-oxyacetoxymalonate are scale inhibitors and removers; Potassium molybdate is an inorganic salt descaling agent; 2-propargylmercaptobenzimidazole is a corrosion inhibitor; sodium hexamethylenetetramine diacetate is a corrosion inhibitor; melamine formaldehyde resin is a binder.

[0018] Stearyl imidazoline silver acetate, a new type of strong antibacterial and fungicide for industrial us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com