Wear-resistant superhydrophobic billboard coating

A billboard and super-hydrophobic technology, applied in anti-fouling/underwater coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve the problems of billboards that cannot be cleaned and billboards that are spotty and mottled, and achieve Good wear-resisting, light-retaining and color-retaining functions, less difficulty in industrial transformation, and excellent hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

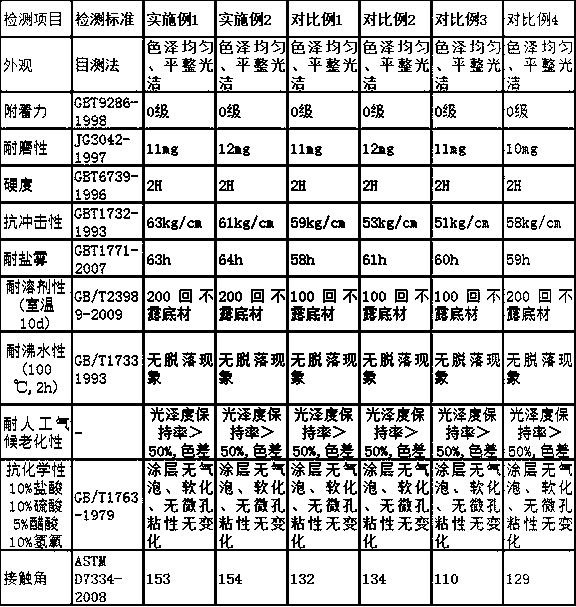

Examples

Embodiment 1

[0022] A wear-resistant super-hydrophobic billboard coating made of the following parts by weight:

[0023] Silicone diacrylate 33, polybutadiene urethane acrylate 21, tripropylene glycol diacrylate 15, polyether acrylate 7, butyl acetate 9, tricycloheptane dimethanol diacrylate 15, N-vinylpyrrolidone 4, epoxy soybean oil acrylate 3, diphenyl iodonium phosphate 0.5, propylene glycol monomethyl ether 5, polysiloxane diacrylate 3, polysulfone 3, acrylic-β-hydroxyethyl Base ester copolymer 4, 4-methylthiopyridone 0.4, fluoropropylene copolymer resin 41.

[0024] A wear-resistant super-hydrophobic billboard coating. The preparation method includes the following steps: the preparation method includes the following steps: (1) First, organic silicon diacrylate, polybutadiene urethane acrylate, and tripropylene glycol Diacrylate, polyether acrylate, butyl acetate, tricycloheptane dimethacrylate, N-vinylpyrrolidone, epoxy soybean oil acrylate are mixed uniformly, and then ultrasonically tr...

Embodiment 2

[0032] A wear-resistant super-hydrophobic billboard coating made of the following parts by weight:

[0033] Silicone diacrylate 12~33, polybutadiene urethane acrylate 11, tripropylene glycol diacrylate 8, polyether acrylate 3, butyl acetate 5, tricycloheptane dimethanol diacrylate 3. N-vinylpyrrolidone 2~4, epoxy soybean oil acrylate 3, diphenyl iodonium phosphate 0.5, propylene glycol monomethyl ether 5, polysiloxane diacrylate 3, polysulfone 3, acrylic acid- β-hydroxyethyl ester copolymer 7, 4-methylthiopyridone 0.6, fluoropropylene copolymer resin 25.

[0034] A wear-resistant super-hydrophobic billboard coating. The preparation method includes the following steps: the preparation method includes the following steps: (1) First, organic silicon diacrylate, polybutadiene urethane acrylate, and tripropylene glycol Diacrylate, polyether acrylate, butyl acetate, tricycloheptane dimethacrylate, N-vinylpyrrolidone, epoxy soybean oil acrylate are mixed uniformly, and then ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com