Method for reducing total nitrogen, total phosphorus and COD in low-molasses alcohol waste mash

A technology for molasses alcohol and waste mash, which is applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of loss of effective components, large land occupation, and high treatment costs, and achieve waste utilization. , the effect of reducing production costs and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

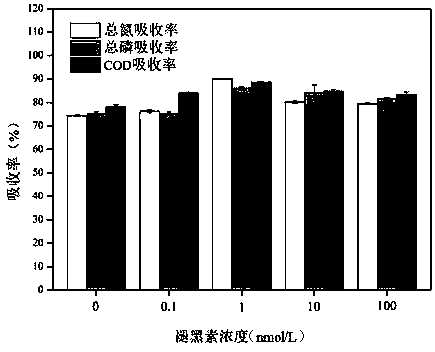

[0019] A method for reducing molasses alcohol waste mash total nitrogen, total phosphorus and COD, comprising the following steps:

[0020] (1) Culture medium preparation: Dilute the molasses alcohol waste mash to a COD value of 2000 mg / L, adjust the pH value to 7.0 with a NaOH solution with a concentration of 1mol / L, and sterilize at 121°C for 20 minutes to obtain a culture medium;

[0021] (2) Microalgae culture: inoculate the microalgae into the medium of step (1), the inoculum amount of the microalgae is 0.1g / L, and the microalgae is Monospina Monoraphidium sp. FXY-10, carried out light shake flask culture, the light intensity was 3800lux, the shaker speed was 145r / min, and the culture temperature was 23°C.

[0022] After culturing for 1 month, the culture product was centrifuged to collect the supernatant, the centrifugation speed was 3500r / min, and the centrifugation time was 5min; the COD multi-parameter photometer (Hana HI83399) was used to measure the total nitrogen, ...

Embodiment 2

[0028] A method for reducing molasses alcohol waste mash total nitrogen, total phosphorus and COD, comprising the following steps:

[0029] (1) Culture medium preparation: dilute the waste molasses alcohol mash to a COD value of 1800 mg / L, adjust the pH value to 7.0 with a NaOH solution with a concentration of 1mol / L, and sterilize at 121°C for 20 minutes to obtain a culture medium;

[0030] (2) Microalgae culture: inoculate the microalgae into the medium of step (1), the inoculum amount of the microalgae is 0.1g / L, and the microalgae is Monospina Monoraphidium sp. FXY-10, then add a concentration of 1 μmol / L melatonin mother solution with absolute ethanol as a solvent, add the concentration of melatonin in the medium to 0.1nmol / L, then carry out light shake flask culture, light The intensity is 3900lux, the rotating speed of the shaker is 150r / min, and the culture temperature is 26°C.

[0031] After culturing for 1 month, the culture product was centrifuged to collect the s...

Embodiment 3

[0034] A method for reducing molasses alcohol waste mash total nitrogen, total phosphorus and COD, comprising the following steps:

[0035] (1) Culture medium preparation: Dilute the waste molasses alcohol mash to a COD value of 2000 mg / L, adjust the pH value to 7 with a NaOH solution with a concentration of 1mol / L, and sterilize at 121°C for 20 minutes to obtain a culture medium;

[0036] (2) Microalgae culture: inoculate the microalgae into the medium of step (1), the inoculum amount of the microalgae is 0.1g / L, and the microalgae is Monospina Monoraphidium sp. FXY-10, then add a concentration of 1 μmol / L melatonin mother solution with absolute ethanol as a solvent, add the concentration of melatonin in the medium to 1nmol / L, and then carry out light shake flask culture, light intensity It is 3800lux, the rotating speed of the shaker is 145r / min, and the cultivation temperature is 23°C.

[0037] After culturing for 1 month, the culture product was centrifuged to collect the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com