Preparation method of titanium oxide nanotube array film

A technology of titanium oxide nanotubes and array films, which is applied in the field of nanotube array film preparation technology, can solve the problems of nanotube array film disorder, unstable nanotube growth, complex and cumbersome preparation process, etc., and achieve stable mechanical structure, The effect of uniform length and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a titanium oxide nanotube array film described in Example 1 comprises the following steps:

[0027] (1) Cut a 10mm×20mm pure titanium sheet, polish it with metallographic sandpaper, and clean it ultrasonically with acetone, ethanol, and deionized water successively;

[0028] (2) Then use a mixed solution formed of hydrofluoric acid, concentrated nitric acid, and deionized water to polish the pure titanium sheet for 30 seconds to obtain a pretreated pure titanium sheet. The volume ratio of the three solutions is 1:4:5;

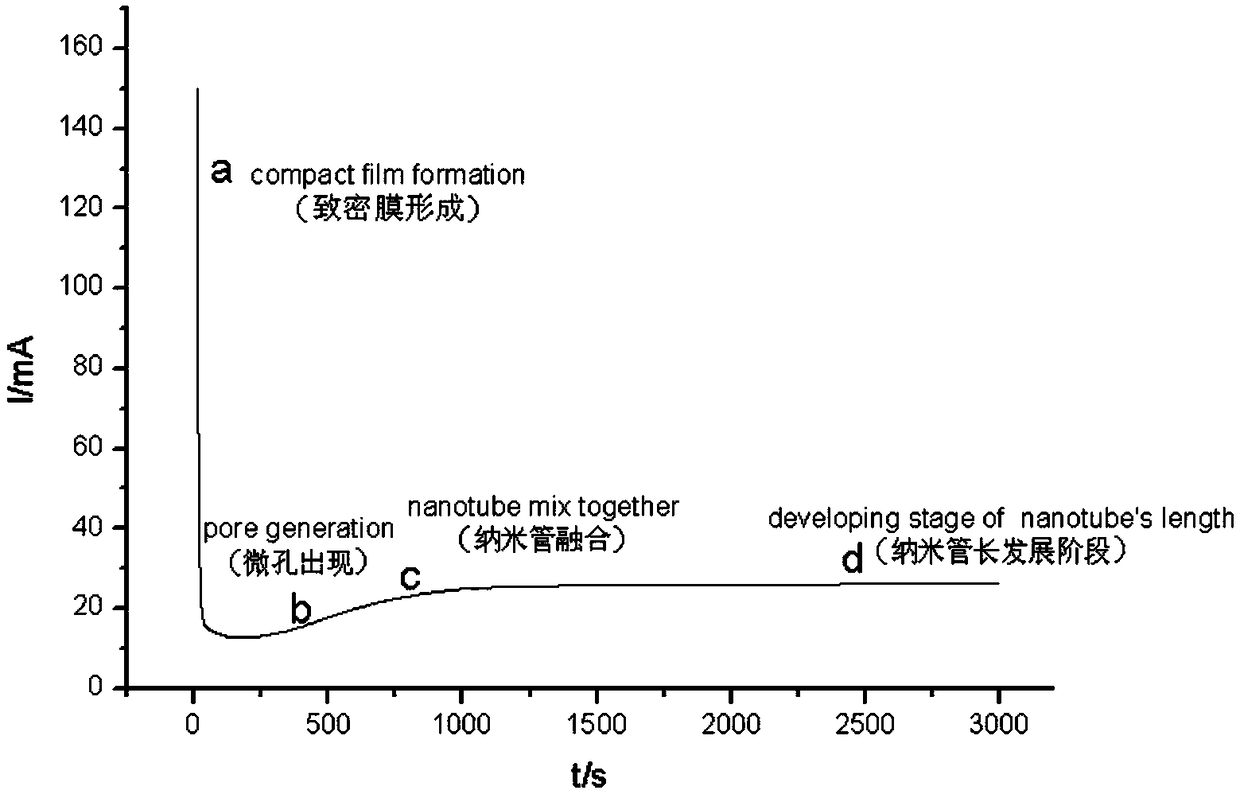

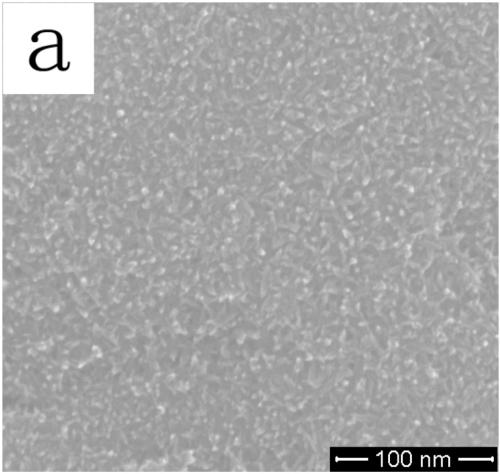

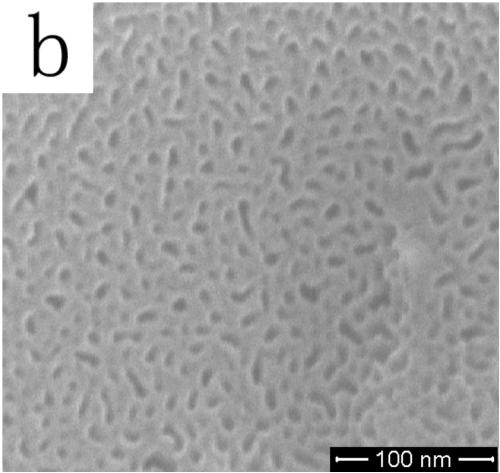

[0029] (3) At room temperature, put the pretreated pure titanium sheet as the anode and the graphite sheet as the cathode into the oxidation solution, and use a DC regulated power supply to provide a voltage of 20V for oxidation treatment for 30s to 3000s, and the surface of the pure titanium will form a structure Regular and ordered high-density titanium oxide nanotube array film;

[0030] The electrode distance between the anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com