Method for fabricating selective textured surface and emitter of silicon solar cell by laser

A silicon solar cell, selective technology, applied in photovoltaic power generation, circuits, electrical components and other directions, can solve the problem of inability to take into account the open voltage current and fill factor, etc., to achieve and fill factor improvement, increase specific surface area, low contact resistance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

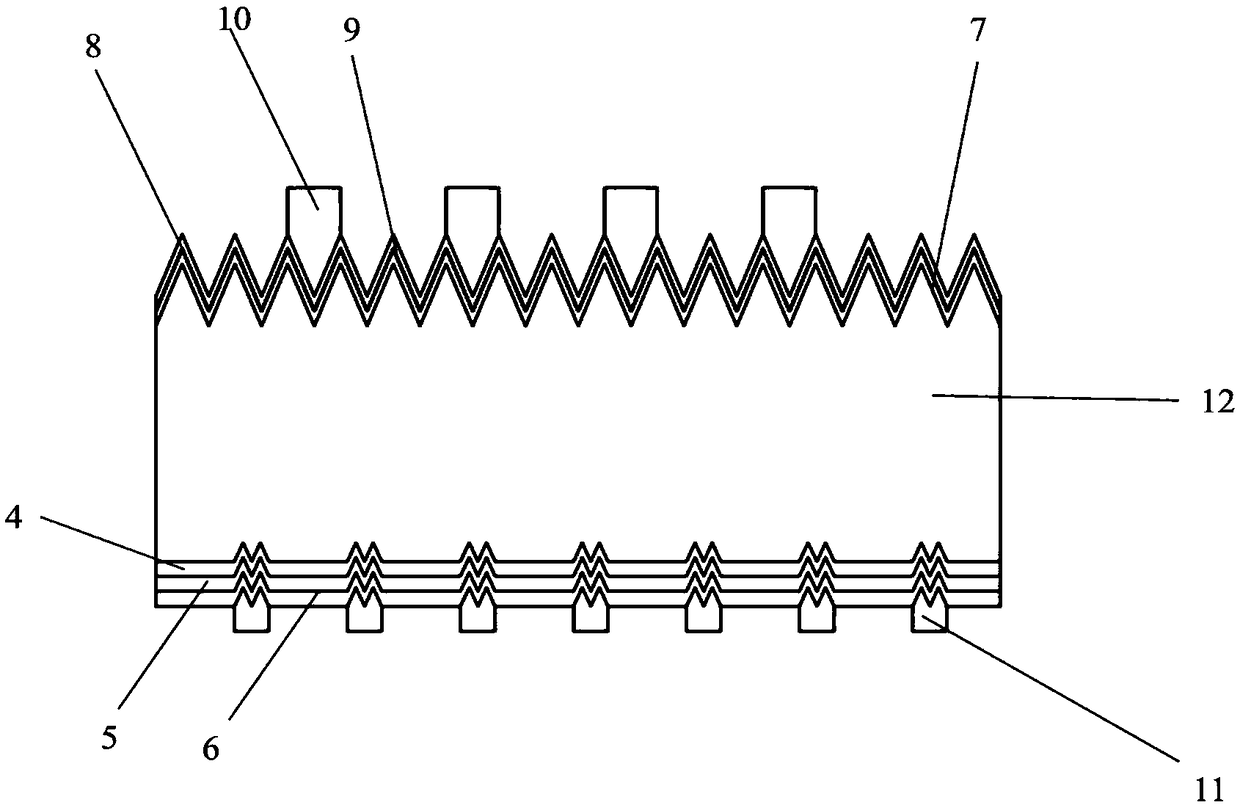

[0032] combine Figure 5 , a method for laser preparing silicon solar cell selective textured surface and emitter, it comprises the following steps:

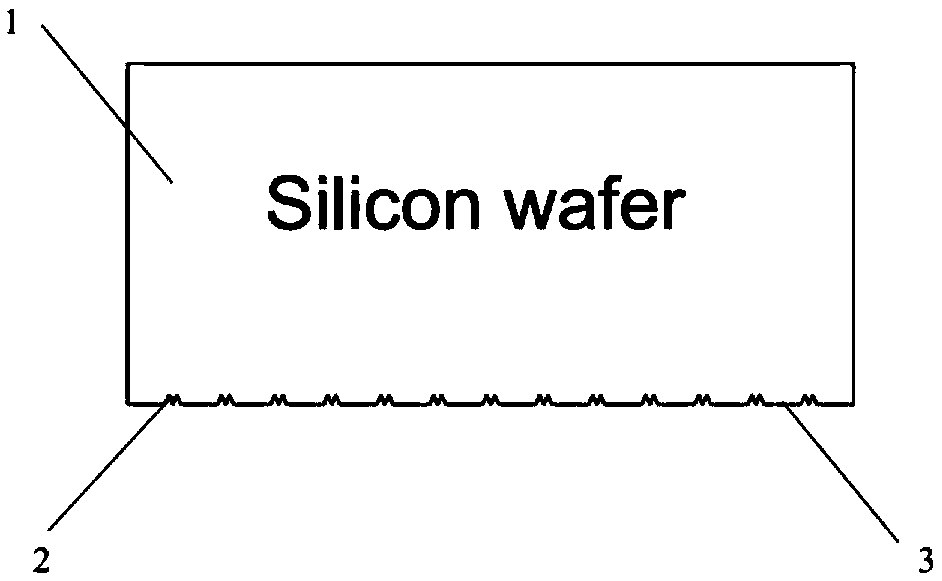

[0033] Step 1: Alkali polishing is performed on the front and back surfaces of the silicon wafer 1;

[0034] Step 2: Carry out laser etching on the back surface of the silicon wafer 1 to prepare the suede surface 2; wherein, the laser wavelength is selected as 532nm, and the spot diameter is 50-80um; the finally formed suede surface 2 structure has a width of 100-160um and a depth of 1 -5um grooves, the number and length of the suede grooves are consistent with the metal fine grid lines on the back;

[0035] Step 3: Clean the silicon wafer with a mixture of hydrofluoric acid and hydrochloric acid, remove the damaged layer, and form a polished surface 3; the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com